Perhaps a regular 7/8” air shifter ram would do the trick. Attach it to the cable Clevis and that would glive you a bit more mechanical advantage. Maybe not as much as a NLR unit but it should be more then what you can get away with with just springs.yes, I drew up a hollow air cylinder, but never made it. the cover would need to be spaced out like a typical lock up for it to work, so kinda defeats half of the purpose of going with it in the first place. i like the anderson/nlr busa version that doesnt poke out of the fairing. my street 12 dynoed at 304sae with 3 hd springs. i ended up putting in 4 just in case it tried to slip in 6th. its a little heavy to pull, where a regular or air lock up would be nicer on the hand, but ill make due. prefer the stealth look of nothing poking out

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Lucy turbo build, and testing

- Thread starter Boosted Cycle Perf

- Start date

More options

Meta tagsMr Brown

Registered

I think he means running it the other way, so it applies pressure on the clutch when the lever is outhows that applying pressure to the pack? what youre describing just helps me pull the clutch in?

Mr Brown

Registered

Gotcha. Maybe that's not what he meant, but that's how it worked in my head....thats not how it works... pushing it away doesnt push on the pack, it just creates extra clearance

Air shifter rams always have 2 ports. Depending on what side you apply pressure to, dictates what way it moves.thats not how it works... pushing it away doesnt push on the pack, it just creates extra clearance

As shown by this crude drawing, if you extended the throw out lever, and connect the ram as shown, and pressurize the lower port it would add (in theory as I don’t know the inner workings of those clutches) pressure to the clutch.

Ju

Just spit ballin.

just re read this... if think I get what you mean now.thats not how it works... pushing it away doesnt push on the pack, it just creates extra clearance

Just spit ballin.

Mr Brown

Registered

That's what I was thinking you were getting at.Air shifter rams always have 2 ports. Depending on what side you apply pressure to, dictates what way it moves.

As shown by this crude drawing, if you extended the throw out lever, and connect the ram as shown, and pressurize the lower port it would add (in theory as I don’t know the inner workings of those clutches) pressure to the clutch.

View attachment 1600560

202mphbusa

Registered

any way to use oil pressure and a vtec solinoid to push some locking pins between the inner and outer hubs to LOCK the clutch so slippage would be impossible

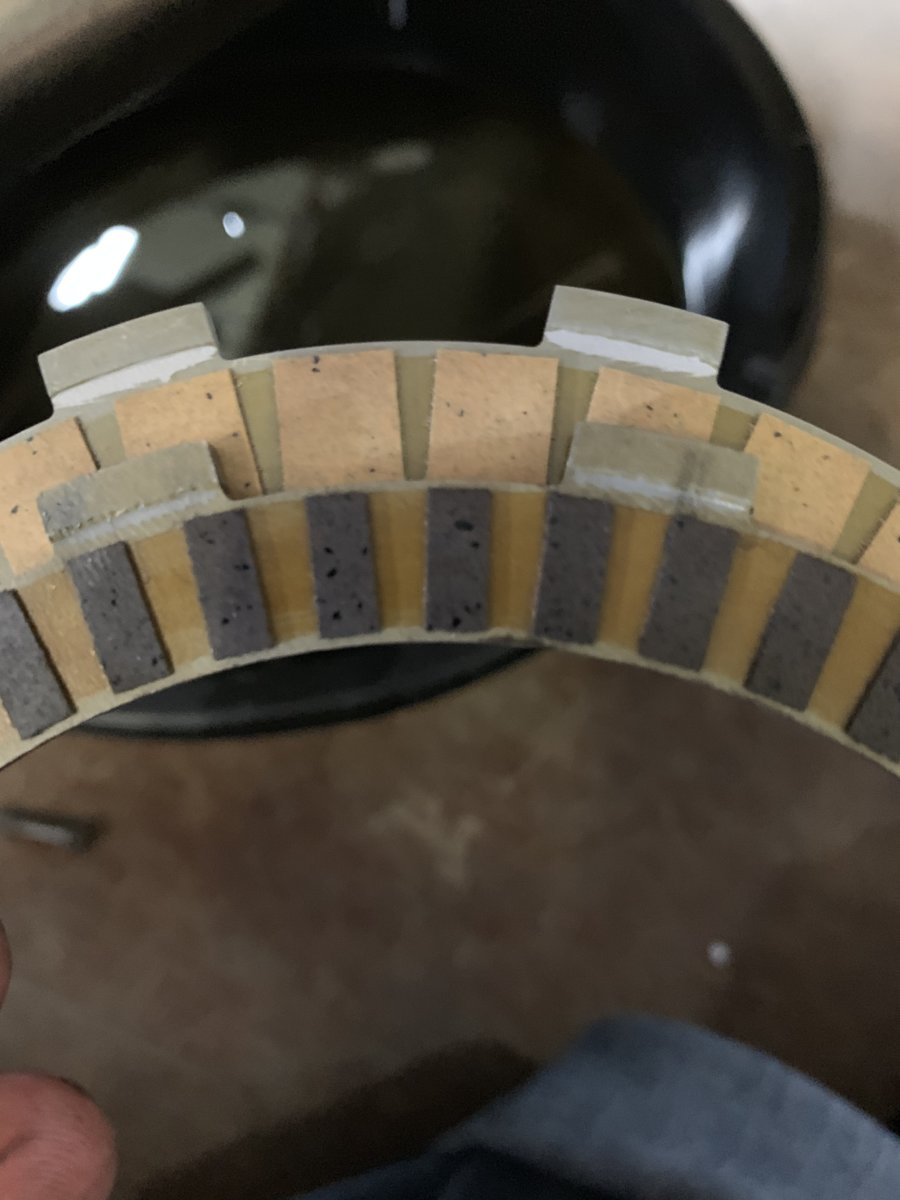

I pulled the clutch to measure the stack height. 1.750... not exactly ideal, but should of worked. The oil was trashed with clutch material so I checked it just in time.

I also noticed that all of the fibers were the small pads. So essentially I had half the gripping force. So I ripped all that out, and put in the new clutch pack I got from C10.

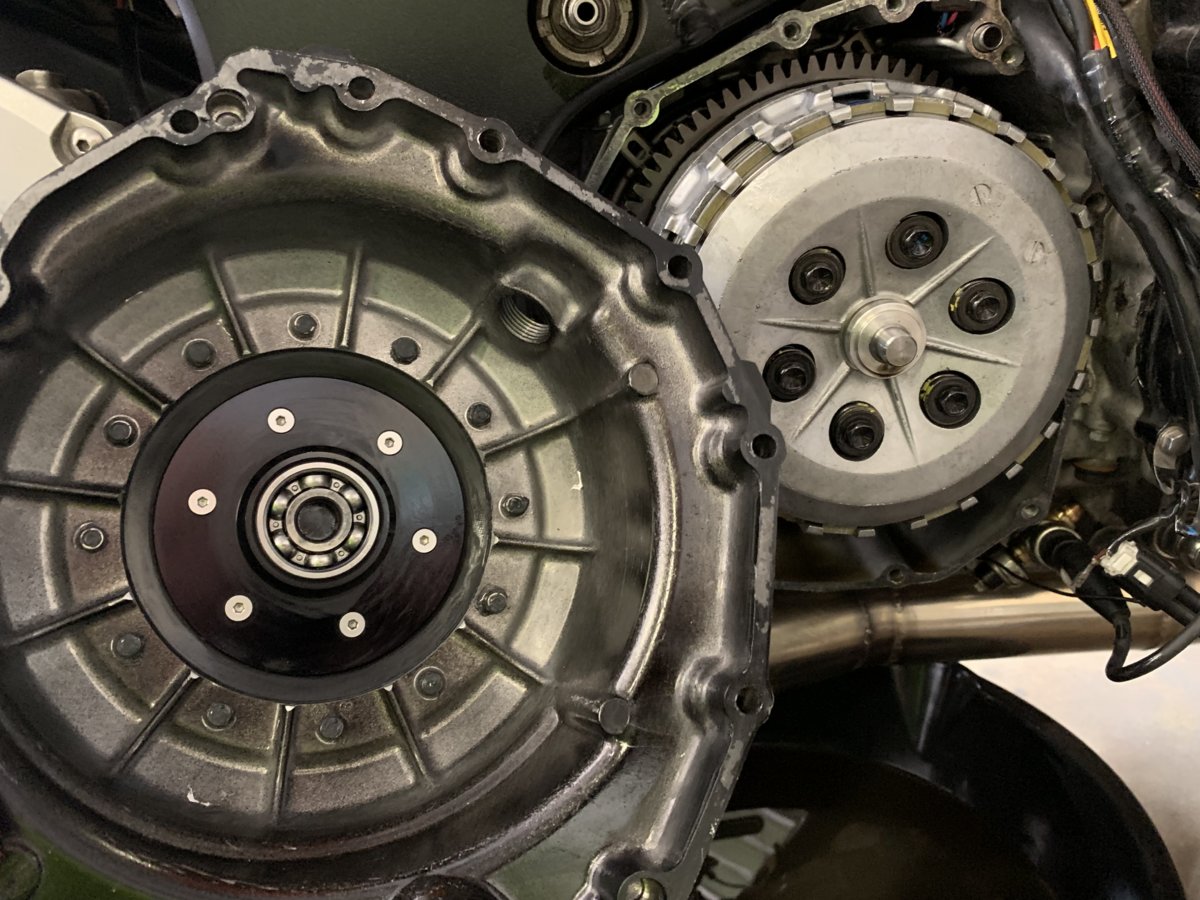

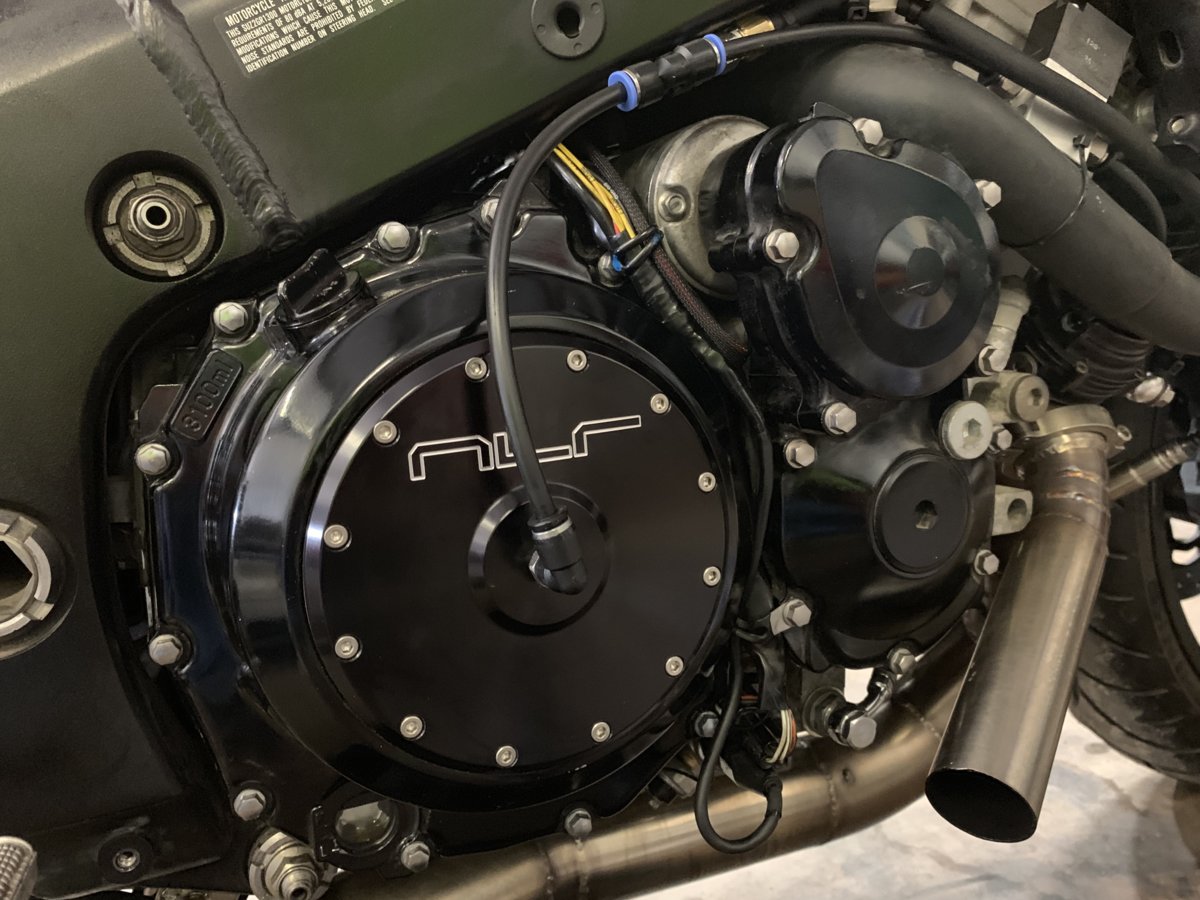

I took the liberty of cursing my existence with pesky air problems and put my NLR clutch on.

And while I was going through some stuff the other day I found an air solenoid, so I wired it up to try the ecu based boost controller since I’ve never actually messed with it. We’ll see how that goes.

I also noticed that all of the fibers were the small pads. So essentially I had half the gripping force. So I ripped all that out, and put in the new clutch pack I got from C10.

I took the liberty of cursing my existence with pesky air problems and put my NLR clutch on.

And while I was going through some stuff the other day I found an air solenoid, so I wired it up to try the ecu based boost controller since I’ve never actually messed with it. We’ll see how that goes.

ali123

Banned

have u ever considered designing ure OWN air feed clutch?I pulled the clutch to measure the stack height. 1.750... not exactly ideal, but should of worked. The oil was trashed with clutch material so I checked it just in time.

I also noticed that all of the fibers were the small pads. So essentially I had half the gripping force. So I ripped all that out, and put in the new clutch pack I got from C10.

I took the liberty of cursing my existence with pesky air problems and put my NLR clutch on.

And while I was going through some stuff the other day I found an air solenoid, so I wired it up to try the ecu based boost controller since I’ve never actually messed with it. We’ll see how that goes.

View attachment 1600594

View attachment 1600595

View attachment 1600596

View attachment 1600597

View attachment 1600598

View attachment 1600599

have u ever considered designing ure OWN air feed clutch?

No, I see no room for improvement on this one.

I haven’t had much time to mess with Lucy lately. But over the last month I’ve been taking care of some maintenance stuff. New forks, front brakes/pads. I also pulled the header off to weld the bung in for the back pressure sensor. And decided to try one more slightly larger turbo. Really just a little bigger on the turbine wheel. The chain and sprockets are shot, but I wanted to make a few pulls to compare without too many variables changing.

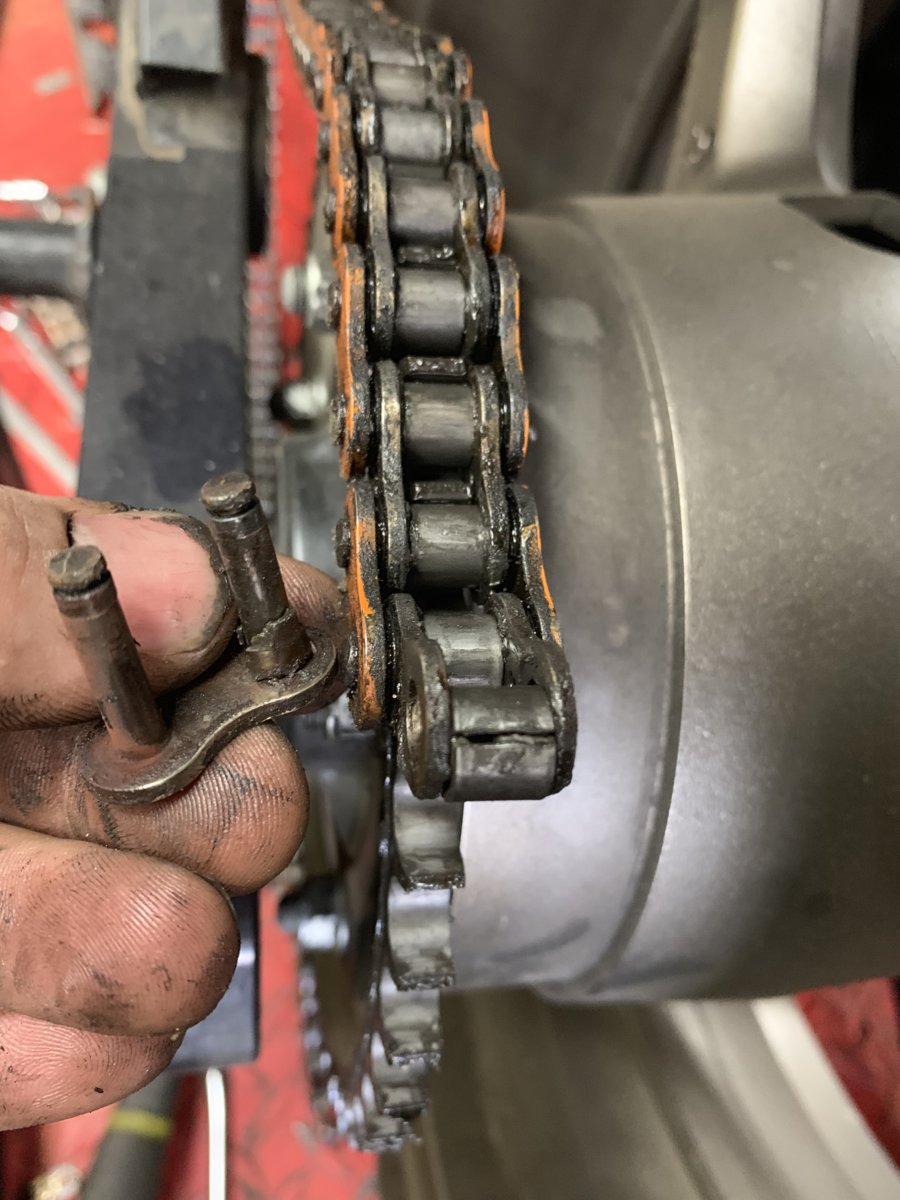

I’m very skeptical of these gains, but I’ll have to revisit the dyno again after doing the chain and sprockets. As you can see from the video, the rollers on the master link came apart.

VP made a delivery. 2 drums of X98.

I’m very skeptical of these gains, but I’ll have to revisit the dyno again after doing the chain and sprockets. As you can see from the video, the rollers on the master link came apart.

VP made a delivery. 2 drums of X98.

busakiller

Registered

awesome to see you test back pressure. That will help a lot when you turn it up. Should help with better sizing turbos? Iam waiting on when you build a intercooler plenum. That be cool to see the temperature drops with that

That is such a smart answer.No, I see no room for improvement on this one.

Knowing when to dig in and when to move on is the sign of a great builder.

Knowing when to dig in and when to move on is the sign of a great builder.The backside on the other turbo was plenty loose enough to get over 400hp. I wanted to try this one to see if I could bridge the 50-ish HP gap between stage 1-2 turbo territory and stage 3. (Getting in to the 500+hp 35R selections)awesome to see you test back pressure. That will help a lot when you turn it up. Should help with better sizing turbos? Iam waiting on when you build a intercooler plenum. That be cool to see the temperature drops with that

Watching back pressure alone will drive you crazy. You’ll see random spikes and dips in the read outs. You have to take other data in to consideration when trying to figure out back pressure.

Such is the life of a shop owner, you never have time to work on your own stuff. Over the last 2 weeks I completed 3 RCC stage 1s minus tunes on two of them, broke down busakillers engine, sent the cylinders and head off to the machine shop, fab’d charge pipes and dumps for a custom build, cut out another run of low profile gauge mounts ($30 shipped!) and a few other odd jobs. I really need help here at the shop but reliable help is hard to come by in my area for some reason.

Anyways one of the bikes last week required a swing arm change so since all the tools were out for that task, I threw Lucy on the lift to swap out the swingarm, chain and sprockets. The chain and sprockets were TRASHED. I’m lucky the chain didn’t come completely apart on the dyno.

The arm is an old school gen 1 velocity arm from my old bike. This is just temporary until I can get the funds together for a Hardcore arm.

Anyways one of the bikes last week required a swing arm change so since all the tools were out for that task, I threw Lucy on the lift to swap out the swingarm, chain and sprockets. The chain and sprockets were TRASHED. I’m lucky the chain didn’t come completely apart on the dyno.

The arm is an old school gen 1 velocity arm from my old bike. This is just temporary until I can get the funds together for a Hardcore arm.

TurboBusa0704

Registered

Close callSuch is the life of a shop owner, you never have time to work on your own stuff. Over the last 2 weeks I completed 3 RCC stage 1s minus tunes on two of them, broke down busakillers engine, sent the cylinders and head off to the machine shop, fab’d charge pipes and dumps for a custom build, cut out another run of low profile gauge mounts ($30 shipped!) and a few other odd jobs. I really need help here at the shop but reliable help is hard to come by in my area for some reason.

Anyways one of the bikes last week required a swing arm change so since all the tools were out for that task, I threw Lucy on the lift to swap out the swingarm, chain and sprockets. The chain and sprockets were TRASHED. I’m lucky the chain didn’t come completely apart on the dyno.

The arm is an old school gen 1 velocity arm from my old bike. This is just temporary until I can get the funds together for a Hardcore arm.

View attachment 1602872

View attachment 1602873

View attachment 1602874

View attachment 1602876

View attachment 1602877

Sure was. Felt part of the roller hit my leg. I was in it to win it, I wanted to see the numbers.Close call

I’ve had such very little time to work on Lucy with every else in the shop. Usually only a few mins here and there before I leave for the day. I was finally able to get back on the dyno and do some comparison pulls against an rcc stage 1 I just finished that’s set up pretty much the same.

While I’m down a few ft lbs of torque from 4-5k rpm, it’s up on power everywhere else. Uncorrected mine was 253 to the rcc 240.

I’m going to run like this for the next few months and hopefully get it to the track in the next few weeks.

While I’m down a few ft lbs of torque from 4-5k rpm, it’s up on power everywhere else. Uncorrected mine was 253 to the rcc 240.

I’m going to run like this for the next few months and hopefully get it to the track in the next few weeks.

Similar threads

- Replies

- 91

- Views

- 10,078