I’m new in the busa world but this is silly. Modifing designs is what progresses things. Boosted saw a flaw or a better way to mount pump so made his own bracket and is using different components. New people making same products is better for consumers. (Supply vs demand). I get why Rcc is upset but if you have the best turbo kit on the planet and do it better then why do you care. Keep doing you and make better and better parts. Without competition there is no progression and product development slows down. It’s absolutely in everything. Combustion engines, turbos, computers, TVs etc. someone designs something, then someone tweaks it to make it better, then the original designer can tweak the new design and make it better and it keeps going that way. The only way to secure your design is to patent it and make tweaks to try to extend The patent when it runs out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Say hello to Lucy, the new shop bike.

- Thread starter Boosted Cycle Perf

- Start date

More options

Meta tagsI have known Rob has been planning turbo kits for some time now, its not new. I really don't care, he can try it if he likes. But it does bug me when I trust someone, refer work to them, and they basically copy a specific part we have made. I know you guys think whats the big deal? You will never understand it and I will not try to explain it, I have better things to do,

Richard

You don’t think anyone else here has made turbo kits that have been copied before. I have, just wasn’t for a busa. Is was a front mount for a Mazda speed 3 way back in the day. Then it was turbo manifolds on Evos. I admittedly was upset at first when I saw copies on eBay selling for 1/3 the price as mine. But then just pushed through it and made mine better and better. Please don’t make the assumption you are the only person who has build, tuned, modified, designed parts on this forum. RCC kits look great and work well. But there

Is always room for improvement. Like maybe switch from old T3 with 4 bold out turbine to the better designed vband in and out?

You don’t think anyone else here has made turbo kits that have been copied before. I have, just wasn’t for a busa. Is was a front mount for a Mazda speed 3 way back in the day. Then it was turbo manifolds on Evos. I admittedly was upset at first when I saw copies on eBay selling for 1/3 the price as mine. But then just pushed through it and made mine better and better. Please don’t make the assumption you are the only person who has build, tuned, modified, designed parts on this forum. RCC kits look great and work well. But there

Is always room for improvement. Like maybe switch from old T3 with 4 bold out turbine to the better designed vband in and out?

Richard has been plagued over the years with people directly ripping off his products, and name. To this very day there’s a company that sells the EXACT version of the original ultra plenum from its original sheet metal design. The company even went as far as to name their turbo company “Ultra turbo systems”. And it just so happened that when you’d google Rcc ultra plenum, that other company just so happened to show up. That company also tends to tell people calling about their products that they’re talking to “Richard”. Very recently I had to call Richard to verify his kits weren’t on sale as a price a prospective customer told me after I quoted him for and actual Ultra set up was way too cheap. The price Conveniently fell in line with that other companies web site.

There’s also a company overseas that was claiming to be or was making rcc products.

But then there’s the small battles on the monthly basis of guys selling used kits which may have a few Rcc parts, but are selling them labeled as Rcc kits, when a majority of the parts are junk. Those are the situations where I’ll volunteerly step in and correct those people.

There’s many other situations I can go on about, as I’ve know of Richard as far back as when he was still working with Dennis WAY back making the first kits back then. So I’ve seen and can appreciate his efforts in doing what he does, at the caliber he does, and consistently. People are quick to roll their noses at the price tag of a turbo kit for a motorcycle as the actual physical parts you receive in retrospect to a car kit is significantly less. Materials are fairly cheap. The cost encured is vastly ate up by labor. Building a proper header that allows the bike to gate properly is a pain in the ass. Porting turbine housings to also further ensure proper gating (especially on gen 2s) is an even bigger pain in the ass. Sourcing and modify other parts so that they work on a tightly packaged motorcycle is flat out time consuming. I can truly understand his frustrations in wanting to protect his products.

With that being said Vband housings suck on bikes. You can’t build a header for a vband housing that fits the bikes properly and also allows for boost to gate low enough. That’s why the on3 kits make so much power on the gen 2. 4lb spring, but they’re making almost 8psi, and around 260-270hp. Funny thing is they contacted me on IG asking why their stuff doesn’t work properly.

Rcc actually uses the old ford 5 bolt housings. Tighter packaging, but those housings have a lot more meat in them where you can properly port the turbine housings. Honestly the best option on the bikes.

As far as my kits are concerned they’re going to be random small runs. As mentioned before, the labor involved to build the kits is just too much for me to be sustainable. It’s more for me to push myself as a fabricator, and force me to learn more and utilize technology and to try some ideas I’ve had from building this bikes from over the years. But also gives some guys the option to go boosted on a more budget minded system that isn’t junk.

Thanks for explaining everything. I should have figured there was a reason vband housings weren’t used and now looking at the manifolds I see how it will be hard to make proper collector.

Sorry Richard if my responses came off harsh. I can only imagine how much crap you have had to deal with and the frustration builds to a point where you have had enough. This has given me a chance to “study” all the kids avail and I must say yours are top notch. Keep up the good work, I don’t think anyone will be able to compete with RCC on the mass scale.

Sorry Richard if my responses came off harsh. I can only imagine how much crap you have had to deal with and the frustration builds to a point where you have had enough. This has given me a chance to “study” all the kids avail and I must say yours are top notch. Keep up the good work, I don’t think anyone will be able to compete with RCC on the mass scale.

Rocketmn

Registered

PIT BULL Stands had the Knock-Off thing happen to them..There's Knock-Offs in so much Sh*t nowadays, its Pathetic Man. I'm not sayin' that's what's happening here and I'm not sayin' it's not. It's almost like R&D doesn't mean anything anymore to people in terms of how much time and money it takes a person or people to design something, and I'm NOT speaking about anyone specific...People are always looking for the bottom dollar and as long as people are willing to buy the so called knock-offs, it will continue. Coming from a Family with several successful businesses, I SO Totally Understand This..It's Fuc*ing Stealing! Again, not aimed at anyone here... Just my 2 cents, as usual..

As promised I’m gonna get all down and dirty with data. The logger finally arrived along with the rest of the sensors. Cool thing about the wideband failsafe is it’s AEM NET compatable, meaning it’s canbus. So that saves a lot of inputs from being used.

Signals I’ll be logging:

Canbus:

Ethanol content

Fuel temp

Boost

AFR

Analog signals will be:

Intake temps

Exhaust back pressure

Fuel pressure

Oil pressure

Rpm

AEM also has a canbus egt set up I’ll be getting here shortly. It’s 8 channel so of course I’ll do all 4 exhaust runners, and I’d like to drill and tap the head down low in the runner. My reasoning for this is to see if intake temps drop post injector when using ethanol fuel vs pump. X98 has 10% methanol added to it so I’m interested to see if that 40hp gain we saw on the last bike I tuned on x98 were because of lowered intake temps from the methanol evaporating in the fuel, or is it for some other reason.

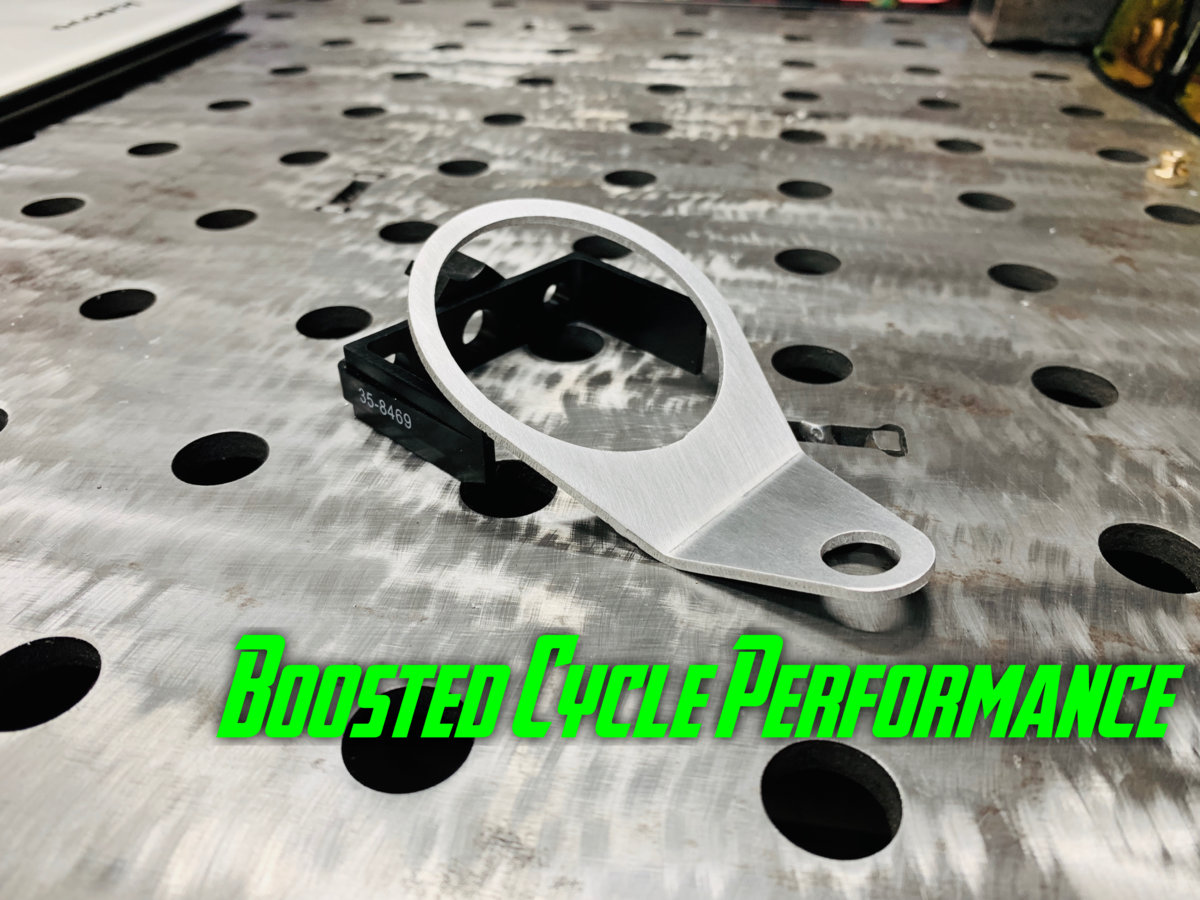

Also next week I’ll have these nice little gauge holders for sale. Low profile, and can see the whole tach vs other options on the market. They’re made in house, out of American manufactured aluminum.

Signals I’ll be logging:

Canbus:

Ethanol content

Fuel temp

Boost

AFR

Analog signals will be:

Intake temps

Exhaust back pressure

Fuel pressure

Oil pressure

Rpm

AEM also has a canbus egt set up I’ll be getting here shortly. It’s 8 channel so of course I’ll do all 4 exhaust runners, and I’d like to drill and tap the head down low in the runner. My reasoning for this is to see if intake temps drop post injector when using ethanol fuel vs pump. X98 has 10% methanol added to it so I’m interested to see if that 40hp gain we saw on the last bike I tuned on x98 were because of lowered intake temps from the methanol evaporating in the fuel, or is it for some other reason.

Also next week I’ll have these nice little gauge holders for sale. Low profile, and can see the whole tach vs other options on the market. They’re made in house, out of American manufactured aluminum.

I like those gauge holders, I'll take one

Right on, they’ll be ready to go next week. Waiting on the shipping envelopes to come in, then I’ll pre package a bunch.

Johnnie Phatt

Registered

Cool thing about the wideband failsafe is it’s AEM NET compatable, meaning it’s canbus. So that saves a lot of inputs from being used.

Its a good thing other people are doing quality work and researching their products. Because I do not have a clue what any other above means. . Which is all the more reason to go with people you can trust to fro a good job

. Which is all the more reason to go with people you can trust to fro a good job

Its a good thing other people are doing quality work and researching their products. Because I do not have a clue what any other above means.

. Which is all the more reason to go with people you can trust to fro a good job

. Which is all the more reason to go with people you can trust to fro a good jobOh crap! Thank you!

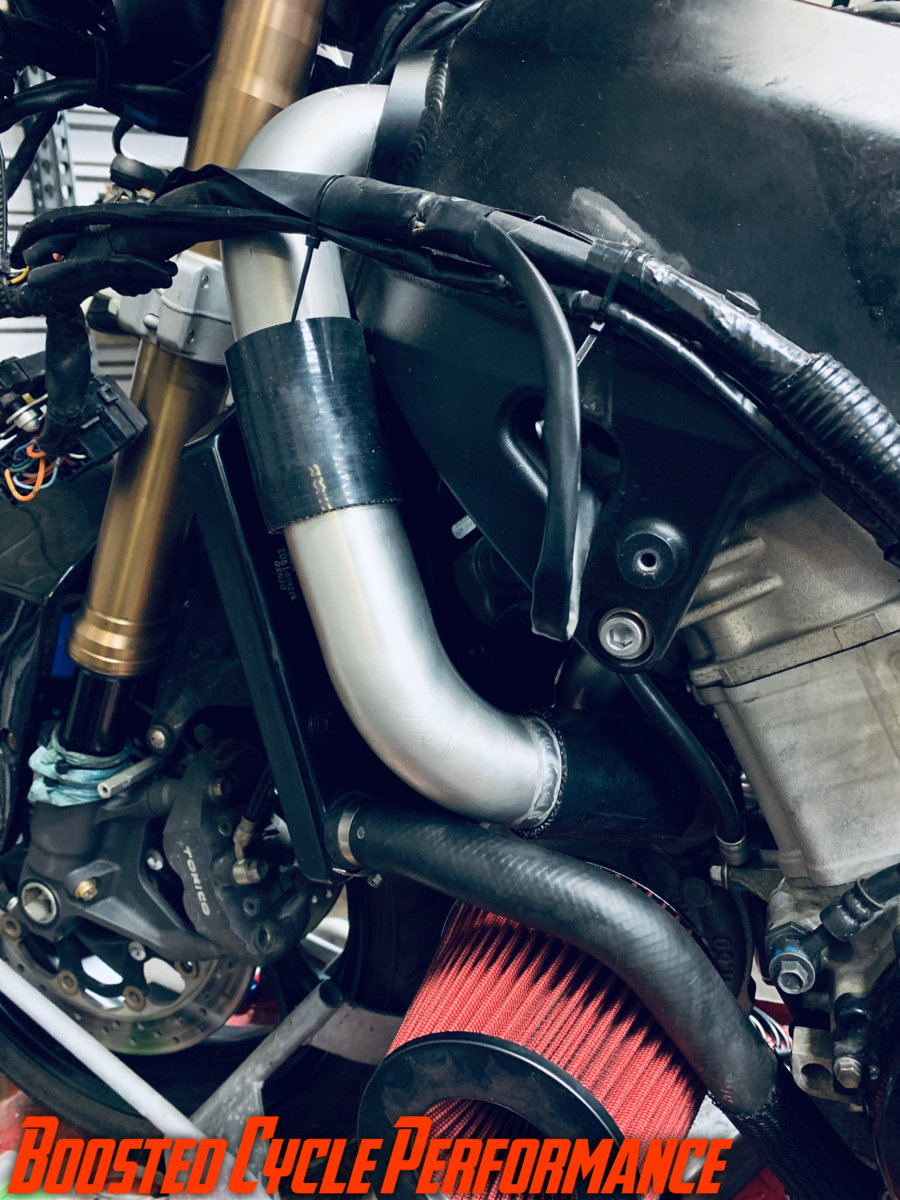

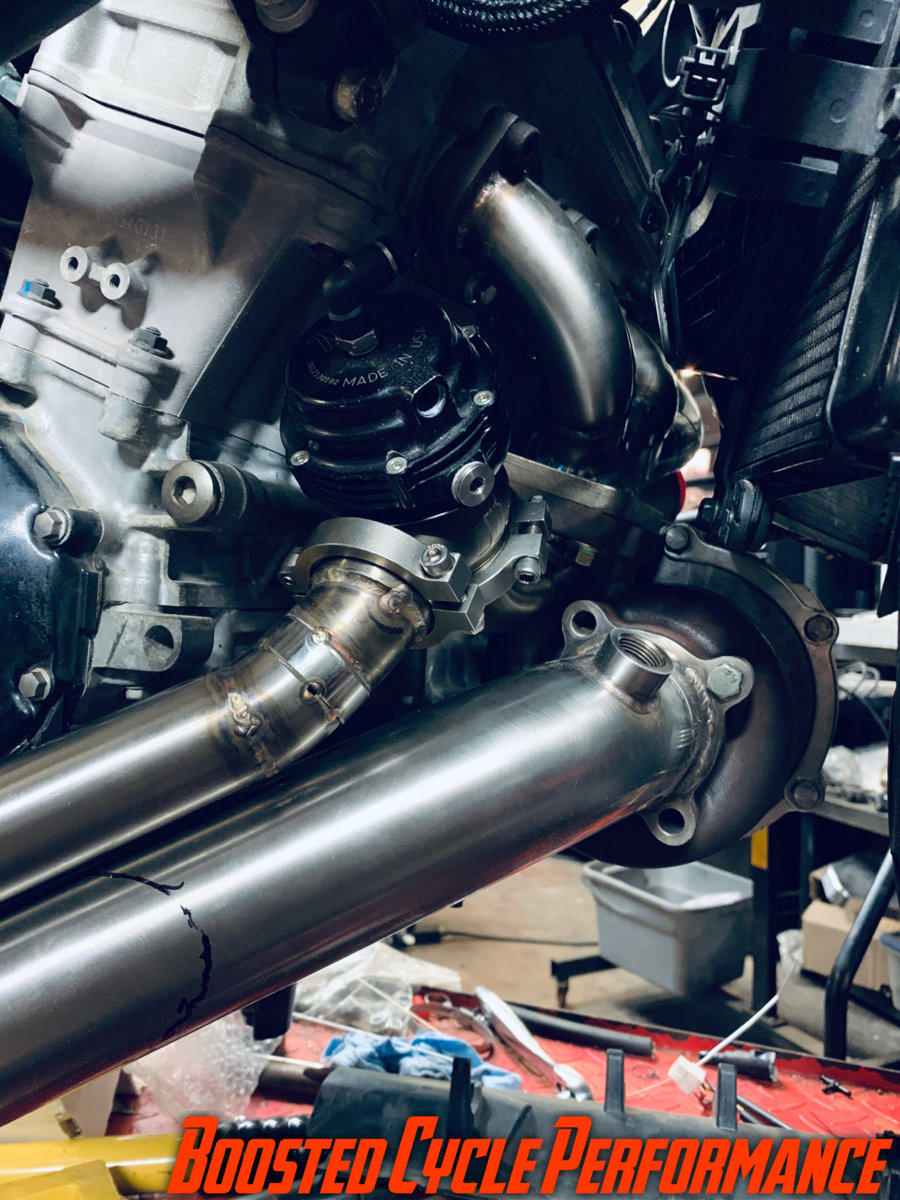

Finally got rid of that stock header. Should make a bit more power now...

Need to figure out where I want to clock the dumps, and then I need to finish the air box.

Need to figure out where I want to clock the dumps, and then I need to finish the air box.

Got ole Lucy fired up today on some old e85, pump fuel concoction. Fired on the first try off of one of my base maps I’ve been developing. Ethanol fuel cold starts are rough with stock ECUs.

I also figured out a concept to enable full flex fuel with a stock ecu. While the idea is in its infancy, from what I’ve seen today it’s looking extremely promising. More to come,

I also figured out a concept to enable full flex fuel with a stock ecu. While the idea is in its infancy, from what I’ve seen today it’s looking extremely promising. More to come,

Bigpopa64

Registered

Johnnie Phatt

Registered

Is it possible or even practicle to have a turbo and not have the air filter poking through the fairing.

Similar threads

- Replies

- 237

- Views

- 30,588

- Replies

- 22

- Views

- 3,830

- Replies

- 7

- Views

- 4,778