Bronto

Registered

Did the Valve job on the Busa. It's not awkward as some motorcycles can be. The alignment marks clearly visible. The assembly not tedious.

Follow the Service Manual proceedures. Removing both side fairings, fuel tank, Airbox and few fairing mount brackets.

First Tip is to cover the throttle body to protect it from getting stuff inside. Seen mechanics use SprayCan plastic tops and tape them over the openings.

Next tip after removing the Vavle cover. Seals and washers can fall off it. Careful to not lose any parts. A small box to put the valve cover in helps keep the parts in order.

Do without a specialty tool tip. With the valve cover off. You'll be able to sight in the alignment marks on the Camshaft gears. Kewl how the frame has openings in the right places, you'll see

Can do the valve clearance measurements setting up TDC 1 and TDC 2 using these marks. Otherwise need huge allen wrench to fit sighting hole to alignment marks on the crankshaft. Alignment to the camshaft gears is more accurate for what it's worth

Can do the valve clearance measurements setting up TDC 1 and TDC 2 using these marks. Otherwise need huge allen wrench to fit sighting hole to alignment marks on the crankshaft. Alignment to the camshaft gears is more accurate for what it's worth

So leave those starter clutch cover sighting hole plates intact.

So leave those starter clutch cover sighting hole plates intact.

I had also to replace a Starter Clutch gear set. While there noticed how the bottom gear on the Cam chain looked. It has two guide tracks holding it to the gear. Even being loose the chain wouldn't skip a gear. This is important when your aligning the chain and camshaft gears later. It's nice to know the cam chain didn't shift on the crankshaft on it's own.

Biggest tip is after all the clearance measurements are done. Set the crankshaft to TDC and leave it there from now on. Don't turn it for any reason until everything is completely back together.

Another tip is to Mark the exhaust side Camshaft gear and chain before removing it. Once the Camshaft retaining bushings are removed. Use a felt pen to mark both chain and camshaft gear. It'll be a mark to align later during reassembly. An easier method then aligning the gear markings to the head. But still double check with the alignment/head/gear markings.

Different way to pull the Buckets, some use suction cups, others use magnets. But the tip here is don't mix the buckets up. Pull a bucket, check the shim and replace it before going on to the next one. Each bucket is uniquely worn to fit in their spot. Mixing them up is not good thing

Not mentioned in the manual is how to get tention in the chain. To double check Camshaft and gear alignment. Using a crescent wrench lightly force the Camshaft position sensor metal pin on the intake camshaft. It should turn easily, don't force it or the pin's history

The Camchain tentioner is removed before removing the camshafts. The tensioner is replaced after the camshafts are reinstalled.

Last tip is replacing the valve cover, put the gasket in the cover first then mount in place. Put the valve cover sealant on the head in the locations noted in the manual.

Think of any other tips post em up.

Before and after the valve job the Busa runs much smoother. Idle through 10.5k RPMs real nice

Gas mileage has gone up few MPGs.

Gas mileage has gone up few MPGs.

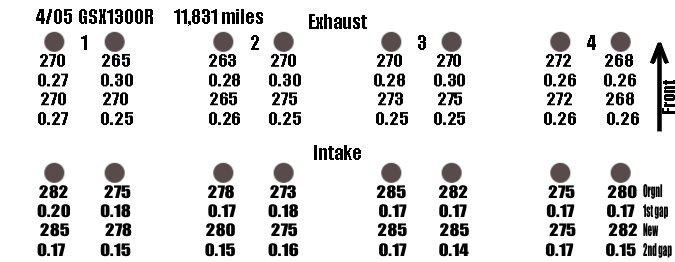

Pictured is Original shim/Clearance/NewShim/2nd clearance. Did some swopping around shims and reused them. Only had to get four new shims. Got the intake to 0.15mm target and exhaust to 0.25mm target. All the clearances were in spec range on the open side (Most gap). Valves wear and close gap clearances.

Follow the Service Manual proceedures. Removing both side fairings, fuel tank, Airbox and few fairing mount brackets.

First Tip is to cover the throttle body to protect it from getting stuff inside. Seen mechanics use SprayCan plastic tops and tape them over the openings.

Next tip after removing the Vavle cover. Seals and washers can fall off it. Careful to not lose any parts. A small box to put the valve cover in helps keep the parts in order.

Do without a specialty tool tip. With the valve cover off. You'll be able to sight in the alignment marks on the Camshaft gears. Kewl how the frame has openings in the right places, you'll see

I had also to replace a Starter Clutch gear set. While there noticed how the bottom gear on the Cam chain looked. It has two guide tracks holding it to the gear. Even being loose the chain wouldn't skip a gear. This is important when your aligning the chain and camshaft gears later. It's nice to know the cam chain didn't shift on the crankshaft on it's own.

Biggest tip is after all the clearance measurements are done. Set the crankshaft to TDC and leave it there from now on. Don't turn it for any reason until everything is completely back together.

Another tip is to Mark the exhaust side Camshaft gear and chain before removing it. Once the Camshaft retaining bushings are removed. Use a felt pen to mark both chain and camshaft gear. It'll be a mark to align later during reassembly. An easier method then aligning the gear markings to the head. But still double check with the alignment/head/gear markings.

Different way to pull the Buckets, some use suction cups, others use magnets. But the tip here is don't mix the buckets up. Pull a bucket, check the shim and replace it before going on to the next one. Each bucket is uniquely worn to fit in their spot. Mixing them up is not good thing

Not mentioned in the manual is how to get tention in the chain. To double check Camshaft and gear alignment. Using a crescent wrench lightly force the Camshaft position sensor metal pin on the intake camshaft. It should turn easily, don't force it or the pin's history

The Camchain tentioner is removed before removing the camshafts. The tensioner is replaced after the camshafts are reinstalled.

Last tip is replacing the valve cover, put the gasket in the cover first then mount in place. Put the valve cover sealant on the head in the locations noted in the manual.

Think of any other tips post em up.

Before and after the valve job the Busa runs much smoother. Idle through 10.5k RPMs real nice

Pictured is Original shim/Clearance/NewShim/2nd clearance. Did some swopping around shims and reused them. Only had to get four new shims. Got the intake to 0.15mm target and exhaust to 0.25mm target. All the clearances were in spec range on the open side (Most gap). Valves wear and close gap clearances.