Boosted_MV

Registered

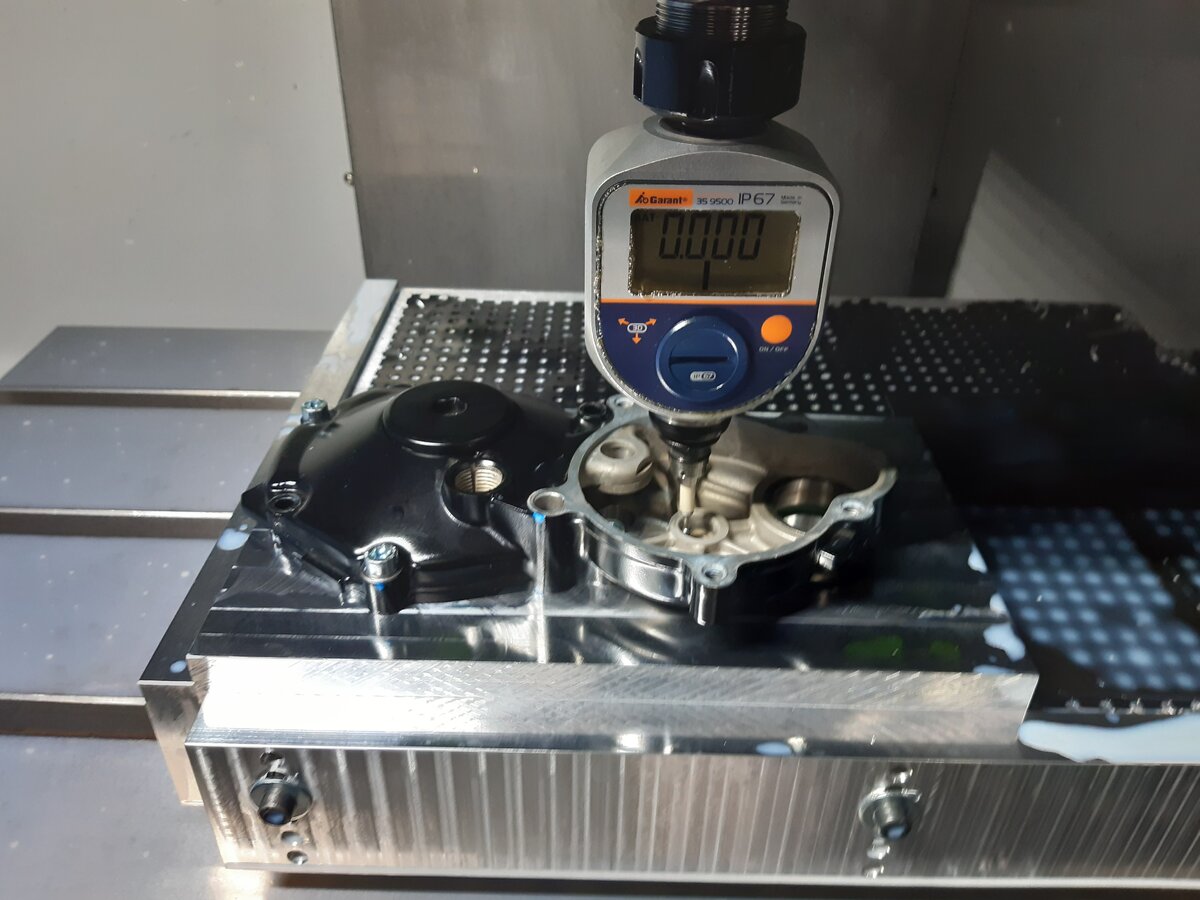

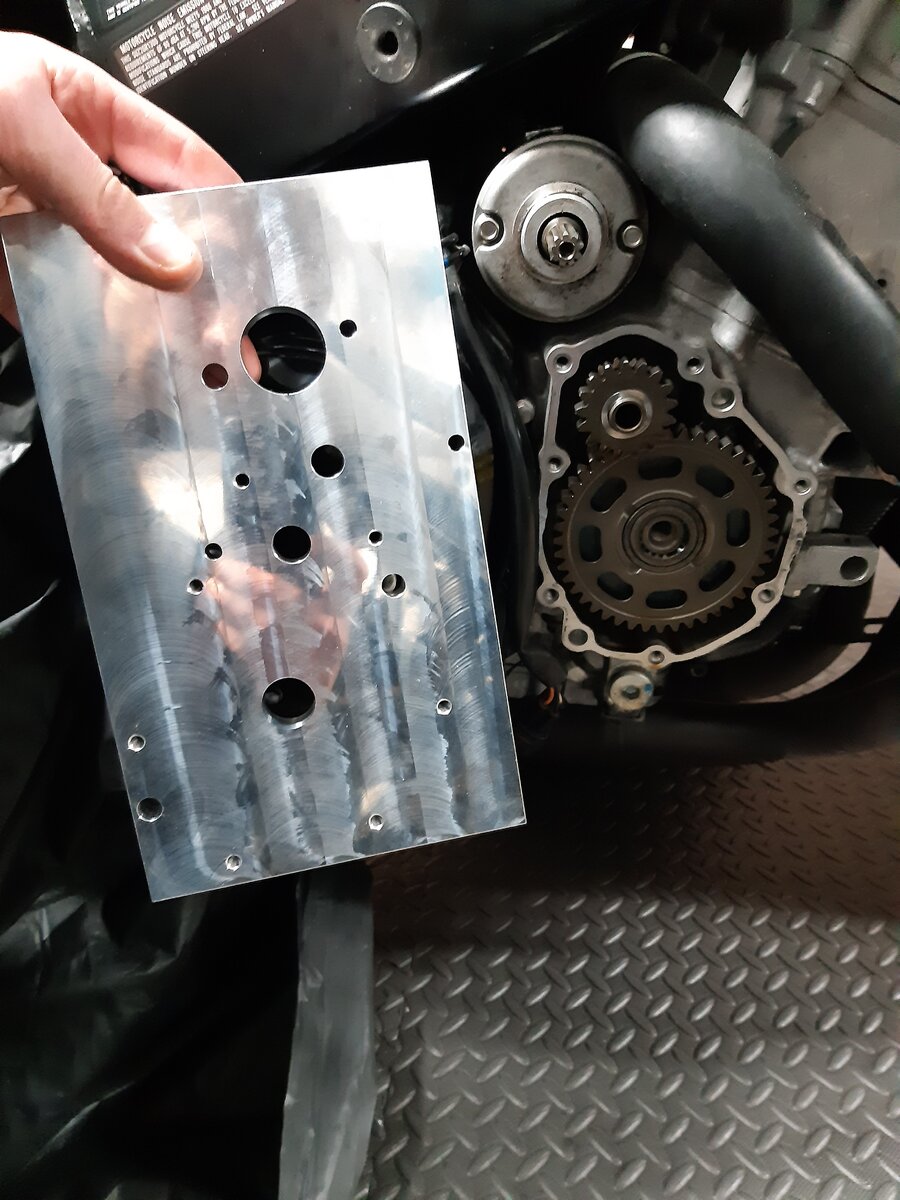

Last week i finished the fixture plate and i measured the 2nd side of the cover starterclutch. The first side fitted perfect to the fixtureplate with the dowelpins in place for exact positioning.

Fixture plate

Measuring 2nd side

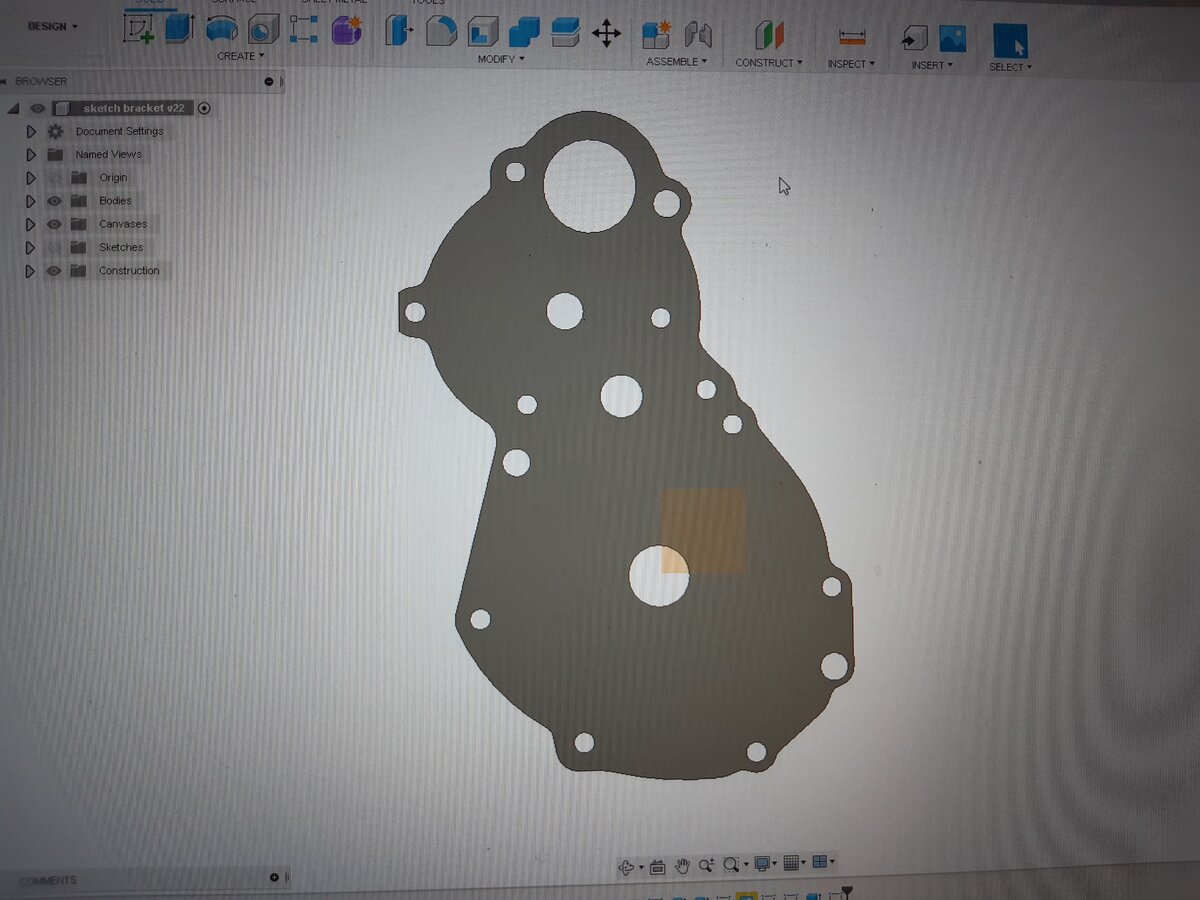

Next up will be milling the contour to make the plate to fit to the engine so i can check my messurement cause its hard to measure the crankshaft position back from the startercluth plate itself. And i can also double check the position of the gears between starter and starterclutch.

Fixture plate

Measuring 2nd side

Next up will be milling the contour to make the plate to fit to the engine so i can check my messurement cause its hard to measure the crankshaft position back from the startercluth plate itself. And i can also double check the position of the gears between starter and starterclutch.

.

.