You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What’s Going On in Your Garage

- Thread starter SSGT_B

- Start date

More options

Meta tagsRacingJake

Registered

Mrs bought me some bike polish so I spent some time on the Gen-3, GSX1400 and B-King.

View attachment 1655763

View attachment 1655764

View attachment 1655765

Tony, for some reason your work shop reminds me of the World's Fastest Indian movie ?

72 & 1/2H

Hi. You can not be to old early 60's I would say. Every day for me is a new pain some where. The old wounds from Nam and crashes never storp hurting. .

I sure like that snowblower....

PeregrineKeith

Registered

Now why couldn’t you live closer to lend a hand with mine!! Awesome looking Glide!Just need to tidy up the wires in the bags but she is done. Did a good walk away and you can hear it clear at 3/4 volume 5 houses down. My neighbors might hate me soon lol

View attachment 1655803

View attachment 1655804

View attachment 1655805

View attachment 1655806

SSGT_B

Registered

Thanks bubba. I’d gladly help out any time. I’m not a big fan of the extra weight the tour pack adds so I keep that off but it is handy at times.Now why couldn’t you live closer to lend a hand with mine!! Awesome looking Glide!

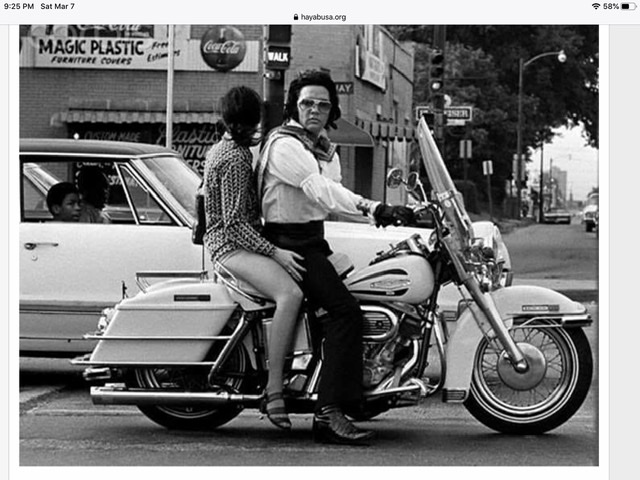

Elvis had one, quite similar.

That's a serious sound system for a bike...Just need to tidy up the wires in the bags but she is done. Did a good walk away and you can hear it clear at 3/4 volume 5 houses down. My neighbors might hate me soon lol

View attachment 1655803

View attachment 1655804

View attachment 1655805

View attachment 1655806

I had a buddy who had a system in his big decker, he'd sometimes play the most obscure music just to make people look....I remember riding with him one time and he was playing Slim Whitman at full blast...he didn't even like Slim Whitman but he played it just annoy anyone he could...

He sure was a character....

Well I got er done! I took two days, cleaning the top side yesterday and the bottom today. Man those headers were nasty. So was the chain and the front of the motor but a lil Simple Green, WD40 and Plexus and it’s all clean and shiny. Topped off the tank and added a lil Seafoam as it was raining right up to my driveway when I got home. Had about a half gallon in the tank when I parked it last Sunday. 94 today and 90s and high 80s for the next week. Maybe I’ll take the Busa out this week and look for a curvy road sign.

Fyi

That won't get the injectors clean.

You need to connect them to 12volts, momentarily, on and off quickly, to make them pulse/open, while spraying cleaner into them(don't leave the pos and neg connected constantly, or you risk burning them up).

Then turn the injector around and repeat, 'back flush' it.

This allows you to see if the spray pattern is correct, and if the injector is working properly.

This is the Only way to clean the gummed up and varnished gas inside the valve, if you don't open it with 12v...you can't completely clean inside them.

Soaking or ultra-sonic will not clean them there.

The screens may need replaced, and the o-rings definately should be.

A light coat of lube on the o-rings for install too, to prevent cuts, tears, or twisting.

13B-RX3

Registered

Thanks for the tip. I have an OTC injector pulser. I pulsed each one for 30 min while they were submerged, heated to 50c as well. As for the flushing, I'll do that tomorrow, after they soak over night. I had this fish gun left over from doing the wife's air conditioner. Figured it would work perfectly. I also have all new seals and screens for the injectors. I'm leaving no stone unturned on this one.Fyi

That won't get the injectors clean.

You need to connect them to 12volts, momentarily, on and off quickly, to make them pulse/open, while spraying cleaner into them(don't leave the pos and neg connected constantly, or you risk burning them up).

Then turn the injector around and repeat, 'back flush' it.

This allows you to see if the spray pattern is correct, and if the injector is working properly.

This is the Only way to clean the gummed up and varnished gas inside the valve, if you don't open it with 12v...you can't completely clean inside them.

Soaking or ultra-sonic will not clean them there.

The screens may need replaced, and the o-rings definately should be.

A light coat of lube on the o-rings for install too, to prevent cuts, tears, or twisting.

mark3evo

Registered

Here is the size of my matchboxHey! I thought no-one in the UK had garages??

Or if they do... they're the size of a matchbox lmao.

ottafish

Registered

Jeeez, you could read that number plate from a passing satellite..

mark3evo

Registered

I prefer not having the police pull me over and issue me a £100 or $110 fine

mark3evo

Registered

I prefer not having the Police pull me over and issue me with a £100 or $110 fineJeeez, you could read that number plate from a passing satellite..

Some of the cops are picky would rather issue a ticket than chase down a guy with a knife

Similar threads

- Replies

- 48

- Views

- 20,097

- Replies

- 34

- Views

- 3,379

- Replies

- 24

- Views

- 1,172