GOOSH!..

<span style='font-size:17pt;line-height:100%'>MOUNTING TIPS FOR HID BALLAST</span>

1. Mount ballast to right (as seated on bike) ram air tube diaganal part. Test fit with cheap double sided tape, sliding nose section on/off to ensure fit.

2. Prior to perm mount clean ram tube with alcohol and let disolve. Use provided double sided tape pad.

3. Get a package of two enclosed, hoover #60 flat vacuume cleaner belts at about $1.99 - $3.00 for the two. (GIANT RUBBER BANDS)

4. Make sure you can "unplug" or "Seperate" wires between ballast and lighting igniter or socket depending on model. You dont want to be removing nose section and have to stop and untape wires to ballast due to light being on nose and ballast on ram tube. If there are no connectors put one in. Note ram air tubes get less vibration and are flater and thicker than inside nose section. Less likely to get damaged in minor crash. *PUT TOWEL ON FRONT FENDER TO AVOID SCRATCHES*

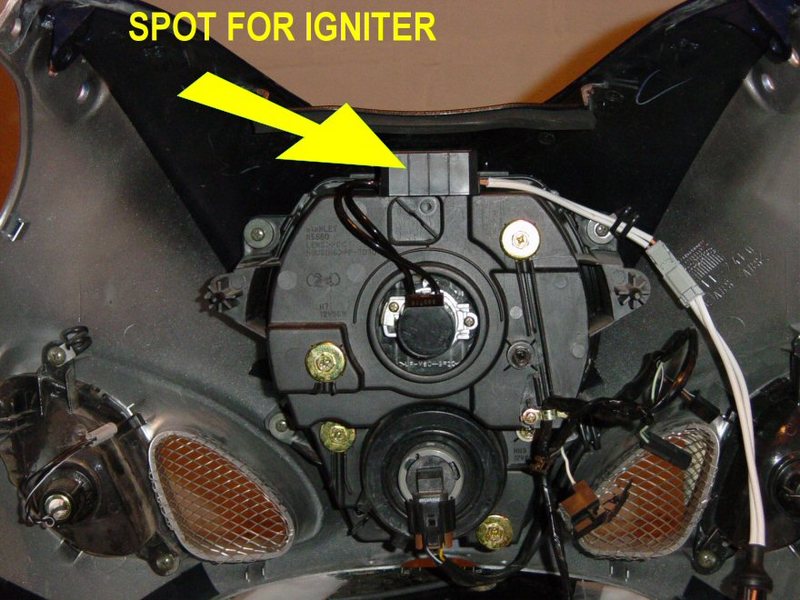

5. Mount igniter on shelf above headlight. Perfect fit. Clean shelf with alcohol. Decent double sided tape works.

6. DONT TOUCH GLASS HID BULB PERIOD. Clean with alcohol lightly and let disolve completely.

7. Stock headlight wiring works but not totally suggested for HID power source. Wont hurt the wires but it's going thru the entire headlight circuit with other stuff on it.

8. Consder putting an on/off switch in to take low current shortage away from ballast during bike start up (starvation).

9. Use a 12v relay. Get power from the bikes battery to power relay. Use headlight wire to "trigger" relay to turn on ballast. Put on/off switch on ground side of main power from battery to relay. Relay power will work all the time bike on or off however headlight wire will only trigger relay to light ballast with key on or bike running. No drain thru bike smaller wire configurations. No flickering due to bad grounding/connections.

10. Do not use HID kits with high tension lines (spark plug wires) and BEND THE LINES.

11. Do not mount ballast in trunk area and run LONG ASSS wires to the front.

12. Re-aim headlight while sitting on bike before putting inner panels back on.

13. Try not to use cheap crimp on connectors, solder it. Too much vibrations.

14. Unless your going back to stock I would move further up the wire and cut the stock plug off. Less problems when soldered. You can always put it back on.

15. Use silcone to completely cover all the contacts on the relay once your satisifed with your hook up to keep moisture out and vibration shorts to a min.

16. Suggestions of relay mounting location. BACK SIDE OF INSTRUMENT CLUSTER FRAME.

17. Glad I could help.

I found a plastic round "cap" to go over the rubber dust boot and put two screws in from the sides to hold it inplace. Then put a decal on it to WARN about voltage. Keeps it clean and neat.

<!--EDIT|ICEMANN

Reason for Edit: None given...|1137005624 -->

<span style='font-size:17pt;line-height:100%'>MOUNTING TIPS FOR HID BALLAST</span>

1. Mount ballast to right (as seated on bike) ram air tube diaganal part. Test fit with cheap double sided tape, sliding nose section on/off to ensure fit.

2. Prior to perm mount clean ram tube with alcohol and let disolve. Use provided double sided tape pad.

3. Get a package of two enclosed, hoover #60 flat vacuume cleaner belts at about $1.99 - $3.00 for the two. (GIANT RUBBER BANDS)

4. Make sure you can "unplug" or "Seperate" wires between ballast and lighting igniter or socket depending on model. You dont want to be removing nose section and have to stop and untape wires to ballast due to light being on nose and ballast on ram tube. If there are no connectors put one in. Note ram air tubes get less vibration and are flater and thicker than inside nose section. Less likely to get damaged in minor crash. *PUT TOWEL ON FRONT FENDER TO AVOID SCRATCHES*

5. Mount igniter on shelf above headlight. Perfect fit. Clean shelf with alcohol. Decent double sided tape works.

6. DONT TOUCH GLASS HID BULB PERIOD. Clean with alcohol lightly and let disolve completely.

7. Stock headlight wiring works but not totally suggested for HID power source. Wont hurt the wires but it's going thru the entire headlight circuit with other stuff on it.

8. Consder putting an on/off switch in to take low current shortage away from ballast during bike start up (starvation).

9. Use a 12v relay. Get power from the bikes battery to power relay. Use headlight wire to "trigger" relay to turn on ballast. Put on/off switch on ground side of main power from battery to relay. Relay power will work all the time bike on or off however headlight wire will only trigger relay to light ballast with key on or bike running. No drain thru bike smaller wire configurations. No flickering due to bad grounding/connections.

10. Do not use HID kits with high tension lines (spark plug wires) and BEND THE LINES.

11. Do not mount ballast in trunk area and run LONG ASSS wires to the front.

12. Re-aim headlight while sitting on bike before putting inner panels back on.

13. Try not to use cheap crimp on connectors, solder it. Too much vibrations.

14. Unless your going back to stock I would move further up the wire and cut the stock plug off. Less problems when soldered. You can always put it back on.

15. Use silcone to completely cover all the contacts on the relay once your satisifed with your hook up to keep moisture out and vibration shorts to a min.

16. Suggestions of relay mounting location. BACK SIDE OF INSTRUMENT CLUSTER FRAME.

17. Glad I could help.

I found a plastic round "cap" to go over the rubber dust boot and put two screws in from the sides to hold it inplace. Then put a decal on it to WARN about voltage. Keeps it clean and neat.

<!--EDIT|ICEMANN

Reason for Edit: None given...|1137005624 -->

:

: