You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel bearing removal

- Thread starter VFRcanada

- Start date

More options

Meta tagsI don't know how tight the fit is on our wheel bearings, but I've changed several sets of dirt bike bearings. After removing the dust seals you could just tap them out with a long punch from the back side.

I would really avoid heating anything if I was you though.

If the old bearings have been around any time at all I'd say replace with new ones. As far as parts go the're pretty cheap insurance.

I would really avoid heating anything if I was you though.

If the old bearings have been around any time at all I'd say replace with new ones. As far as parts go the're pretty cheap insurance.

Last edited:

I use a blind bearing puller set.

Example Here

Example Here

mike1180

Banned

Either the long punch from the back, or the blind bearing puller works well.

Pry the dust seals off first.

I wouldn't heat anything either.

If you take a bearing out it is done and you should use new ones.

I put a little antiseize compound on the outside of the new bearing and it goes in easier, and will come out next time easier.

Pry the dust seals off first.

I wouldn't heat anything either.

If you take a bearing out it is done and you should use new ones.

I put a little antiseize compound on the outside of the new bearing and it goes in easier, and will come out next time easier.

I wouldn't recommend anti-sieze on your bearing race. The last thing you want is a slippery surface on a pressed fit. The two surfaces are made to fit tight so the race has no chance of any movement throughout it's life. When a bearing begins to wear out, many times they begin to drag creating friction by binding. If there is anti-sieze between the bearing's race and the hub, it can easily spin inside the hub and ruin your wheel.

Warchild

Banned

100% correct. Never re-use bearings that have been drifted out.If you take a bearing out it is done and you should use new ones.

However, concur with Tufbusa in that it is generally unnecessary to place any lubricating substance in the outer race prior to installation.

The common method is to place the new bearings in the freezer for several hours prior to gently drifting them in place (bearings only, of course... not the dust seals).

If you don't have a proper bearing driver, simply use the old bearing as a drift. You can use a heat gun, set on medium, to *gently* heat up (expand) the wheel hub where the bearing resides. Then your (frozen) new bearing will almost drop into place.

mike1180

Banned

I wouldn't recommend anti-sieze on your bearing race. The last thing you want is a slippery surface on a pressed fit. The two surfaces are made to fit tight so the race has no chance of any movement throughout it's life. When a bearing begins to wear out, many times they begin to drag creating friction by binding. If there is anti-sieze between the bearing's race and the hub, it can easily spin inside the hub and ruin your wheel.

Mine were really tight in there.

I almost had to destroy them to get them out.

I don't know about others but there is no chance of them spinning on mine, they were in way too tight.

Even with the lube of the anti seize they were reallly hard to get back in.

I only use a small dab of the anti seize, to stop the different metals from corroding and seizing them in place.

You are right, if they are in there loose, don't use the antiseize.

mike1180

Banned

I don’t like to tap on the bearing with anything at all.

There is a chance of brinneling even if you use the old bearing to drive them in.

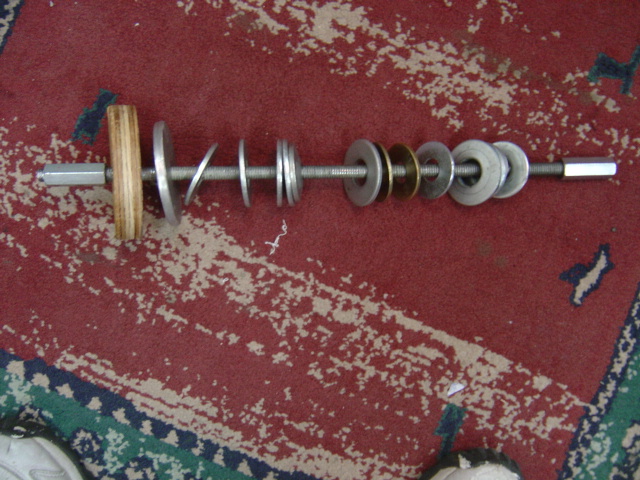

You can use a bolt or threaded rod to suck them in one side at a time.

I made a cheap tool that works real well, with different sizes of washers to fit the bearings.

All Balls Products

REMOVING WHEEL BEARINGS:

When you knock a bearing out of a wheel, for chroming, powdercoating, etc., you are fundamentally destroying that bearing. In fact, there's no other way to get it out without destroying it because it's pressed in on the outer diameter but access to the bearing is from the inner diameter. So you're putting an impact force across the balls of the bearing, which damages it. It's called loading across the bearing races. You're putting little microscopic dents into the ball and the race, and over time they get aggravated. The technical term is brinneling; when you put a shock force on an outer race to an inner race across the balls, that's what you get.

There is a chance of brinneling even if you use the old bearing to drive them in.

You can use a bolt or threaded rod to suck them in one side at a time.

I made a cheap tool that works real well, with different sizes of washers to fit the bearings.

All Balls Products

REMOVING WHEEL BEARINGS:

When you knock a bearing out of a wheel, for chroming, powdercoating, etc., you are fundamentally destroying that bearing. In fact, there's no other way to get it out without destroying it because it's pressed in on the outer diameter but access to the bearing is from the inner diameter. So you're putting an impact force across the balls of the bearing, which damages it. It's called loading across the bearing races. You're putting little microscopic dents into the ball and the race, and over time they get aggravated. The technical term is brinneling; when you put a shock force on an outer race to an inner race across the balls, that's what you get.

Mine were really tight in there.

I almost had to destroy them to get them out.

I don't know about others but there is no chance of them spinning on mine, they were in way too tight.

Even with the lube of the anti seize they were reallly hard to get back in.

I only use a small dab of the anti seize, to stop the different metals from corroding and seizing them in place.

You are right, if they are in there loose, don't use the antiseize.

The race is tight in the hub by design. With the use of a proper puller, they come out with ease.

suzuki4life

Banned

I use axle grease.

mike1180

Banned

The race is tight in the hub by design. With the use of a proper puller, they come out with ease.

I hear that!

But if I had a dollar for everything that "should be" or "should work" and didn't, I would be a very rich man.

I hear that!

But if I had a dollar for everything that "should be" or "should work" and didn't, I would be a very rich man.

Yep, I hear ya man! And if I had a dollar every time someone jury rigged something halfassed to make it work, I'd be a very rich man too.

suzuki4life

Banned

I beat them out and then press or tap them in.

Similar threads

- Replies

- 10

- Views

- 1,626