Mythos

Registered

OEM Footpeg Bracket Removal/

Sato Rearsets Install

Sato Recomends fully installing their rearsets and then disassembling after the desired height adjustments are determined. Thread locking agent may then be applied to all bolts, including those in the parts which come preassembled. In this tutorial I suggest applying thread locking agent immediately upon installation unless the bolts need to be removed or loosened for adjustment purposes. In these cases, I have stated to not apply thread locking agent until the parts have been properly adjusted.

The torque specs in the Sato installation instructions are 7-8 foot pounds for the 6mm bolts. I found that the hex in the 6 mm button head bolts started to strip at around 5 foot pounds. I recommend using nonpermanent thread locking agent on these bolts and torquing to no more than 3 foot pounds or just hand tighten good and snug. Sato torque specs for the 8mm bolts is 16-17 foot pounds. I used 15 foot pounds on these and had no problems with stripping. Henceforth in my tutorial, I specify the torque value that I actually used or the term “hand tight†to provide final tightening information.

I suggest taking the following preliminary steps to help with adjusting the pedal height when reinstalling the footrest assemblies or installing the aftermarket footrest.

Photograph the left and OEM right footrests so that there will be a visual indicator of the height the gear shift lever and the rear brake pedal were adjusted to. This may be handy for reinstalling the OEM footrest or adjustment of a gear shift lever on aftermarket footrest assemblies.

Also photograph the the shift linkage rod for reference if the gear shift lever should need to be adjusted exactly as it was. You may mark the rod with a Sharpie marker to show exactly where the jam nuts were tightened to.

For the right OEM footrest assy removal, refer to step 11 for an explanation as to how the rear brake pedal adjustment may be marked.

Tools:

Sharpie marker

small flat blade screwdriver

needle nose pliers

4mm hex tool socket

6mm hex tool socket

Two 10mm open end wrenches

vise grips

12mm open end wrench

nonpermanent thread locking agent

5mm hex tool socket

12mm box end wrench

0-50 ft lb torque wrench

sandpaper

Electrical tape

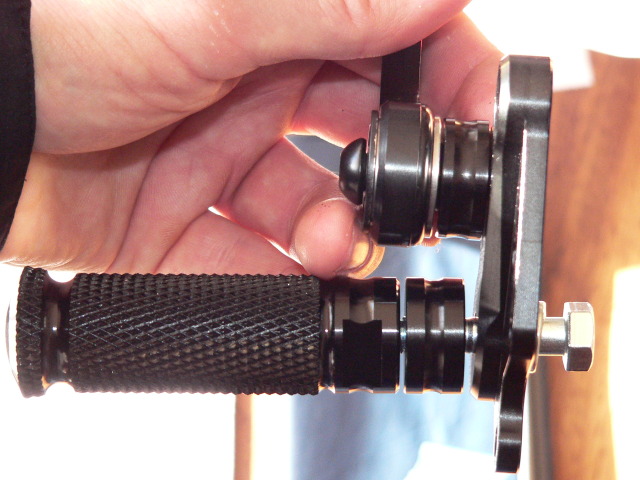

Zip tie

13 mm open end wrench

sandpaper

rag

white lithium grease

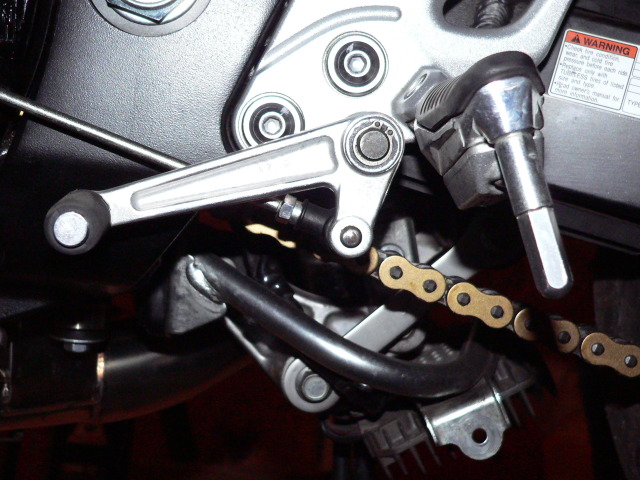

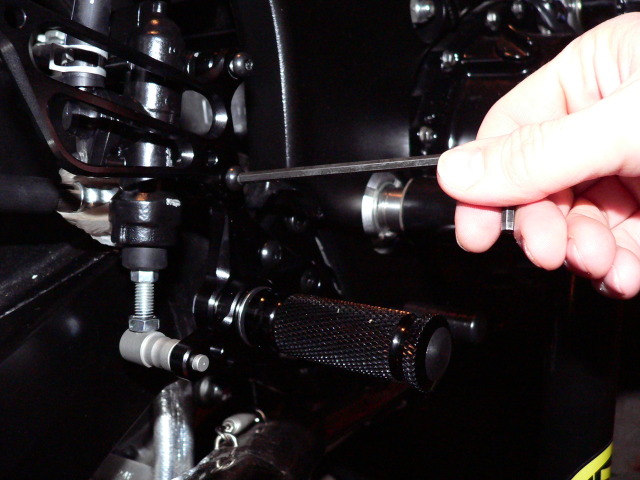

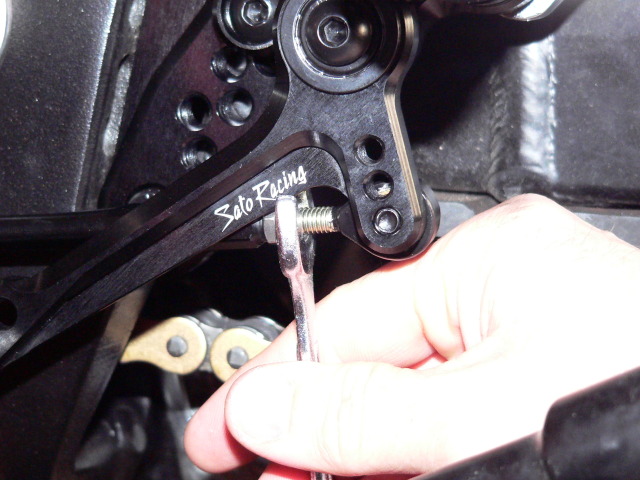

Footrest Bracket Removal, Right Side

1. Turn the rear brake pedal joint pin so that the two bent over stems of the cotter pin are accessible. It will be easier to turn the pin if pressure is applied under the joint so that the joint is lifted slightly. Straighten the cotter pin stems using a small flat blade screwdriver and a needle nose pliers. Pull the cotter pin out of the joint pin.

2. There is a small washer on the joint pin to the inside of the joint. Remove the washer.

3. Push up under the master cylinder/brake pedal joint and remove the joint pin.

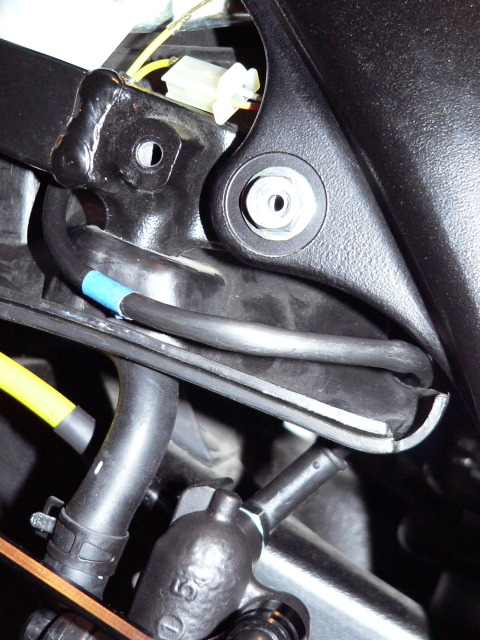

4. Remove the two bolts that fasten the master cylinder to the inside of the heel guard

using a 4mm hex tool.

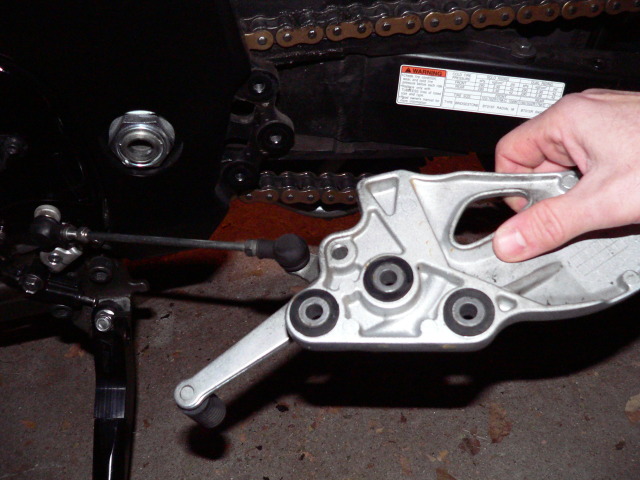

5. Remove the footrest bracket using a 6mm hex tool.

6. Disconnect the rear brake light sensor wire by pressing the point on the tine in and pulling the connectors apart. Remove the right footrest assembly.

Footrest Bracket Removal, Left Side

7. Loosen the jam nut at the forward heim joint using a 10mm open end wrench.

8. Remove the 3 mounting bolts using a 6mm hex tool.

9. Turn the entire left footrest assembly counter clockwise to unthread the shift rod from the forward heim joint. Remove the left footrest assembly. The gear shift lever adjustment of the shift linkage rod is left unchanged for reinstallation.

Sato Rearset Install, Right (Brake Pedal)

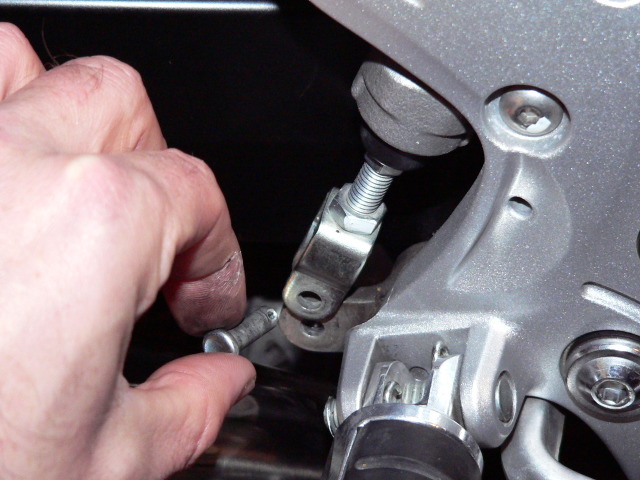

10. Clamp a vise grips onto the joint at the bottom of the rear brake master cylinder as shown. Use a 12mm open end wrench to loosen the locknut.

Do not place a screwdriver through the pivot holes in the joint to brace the joint while loosening the jam nut. The side plates of the joint will bend from the twisting force. Vise grips are the way to go on this.

11. Remove the joint and the nut inside of it.

I used a Sharpie on the stud threads to mark the position of the locknut for reinstallation reference.

12. Place an 8mm socket head bolt through each of the two mounting holes in the right base plate. Place a spacer behind the base plate on the threads of each 8mm bolt.

13. Use nonpermanent threadlocking agent and install the right base plate to the frame using a 6mm hex tool socket. Torque base plate mounting bolts, 15 foot lbs.

14. The brake pedal and right foot peg are preassembled to the right step plate. Tighten the M6 x 20mm screw snug into the brake pedal tip with a 4mm hex tool. Do not apply thread locking agent.

15. Attach the right step plate (with foot peg and rear brake pedal installed) to the right base plate. Choose one of the height positions and thread the two 8 mm button head bolts into the proper holes. Tighten the two 8mm button head socket bolts snug with a 5mm hex tool. Do not apply thread locking agent.

16. Slide the two 6mm button head screws through the right heel guard and the right right step plate. Thread the screws into the holes of the rear brake master cylinder. Leave these screws loose for the time being.

The downspout from the rear brake reservoir will press up into the recess in the undertail.

17. Thread the rear brake rod onto the stud of the rear brake master cylinder. Make sure that the flat of the rear brake rod faces up at the locknut and the peg faces the rear brake pedal.

I placed the locknut at the same height as it had been tightened against the OEM pivot joint. I tightened the rear brake rod up to it.

18. Place the washer onto the rear brake rod peg and then place the peg through the hole at the back of the rear brake pedal. Use a 4mm hex tool to snug the the two 6mm bolts that fasten the heel guard and the master cylinder to the step plate. Use a 12mm open end wrench to tighten the lock nut against the rear brake rod. Do not install the E clip to the brake rod peg yet.

The stud on the rear brake master cylinder is mounted flexibly. The bottom end can be tilted in any direction to help fit the brake rod peg into the hole in the pedal. The heel guard/master cylinder bolts should also be loose while fitting the peg to the hole to allow some movement of the entire master cylinder.

Rear Brake Light Pressure sensor Switch

19. Drain the rear brake system (see https://www.hayabusa.org/forum/maintenance-do-yourself/170084-genii-front-rear-brake-fluid-clutch-fluid-bleed-drain.html, Introduction and steps 13-18) and remove the banjo bolt from the rear master cylinder using a 12mm box end wrench. Place the threads of the brake light pressure sensor switch through the brake line fitting with a washer on either side of the fitting. Thread the pressure sensor switch with washers and brake line fitting into the master cylinder. Tighten the pressure sensor switch. Torque rear brake master cylinder banjo bolt 16.5 foot lbs. Rout the wire into the tail up to the rear brake light wire as shown.

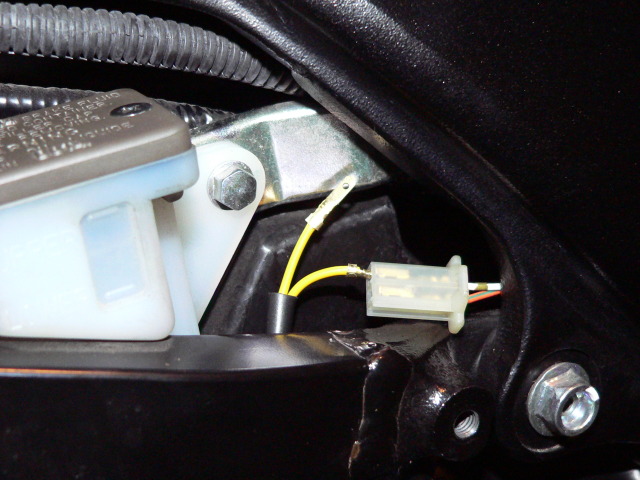

20. press the contact from each wire into the rear brake light connector lead. Either contact may go to either side of the connector regardless of polarity.

I sanded the contacts down a bit by rubbing them against sandpaper so they would fit into the connector smoothly.

21. Electrical tape the wires to the connector lead so they do not pull out. Zip tie the brake light pressure sensor switch wire to the frame as show. Fill and bleed the rear brake system with fresh brake fluid (see https://www.hayabusa.org/forum/maintenance-do-yourself/170084-genii-front-rear-brake-fluid-clutch-fluid-bleed-drain.html, Introduction and steps 13-21).

Sato Rearset Install, Left (shift pedal)

22. Install the left base plate to the frame using a 6mm hex tool and nonpermanent thread locking agent on the two M8 x 25mm socket head screws. Torque base plate mounting bolts, 15 foot lbs.

23. Install the shift pedal to the right kick plate. Place the foot peg bearing collar on the M8 x 35mm button head screw between the left step plate and the shift pedal. Use a 5mm hex tool hex tool to tighten the shift lever screw snug. Do not Use thread locking agent.

24. Fasten the shift pedal tip to the shift pedal. Tighten the M6 x 20mm screw snug using a 4mm hex tool. Do not use thread locking agent.

25. Assemble the foot peg, foot peg collar, lock washer and the M8 x 45mm bolt to the left kick plate as shown below. Use a 13 mm box end wrench to tighten the bolt snug.

26. Thread the M8 x 15mm button head screws through the left step plate and into the left base plate. snug them up with a 5mm hex tool.

27. Use a 4mm hex tool and non permanent thread locking agent to attach the left heel guard. Torque the heel guard screws to 3 foot lbs.

28. Assemble the reverse jam nut to the Sato heim joint by threading it all the way to the top of the threads. Thread the heim joint and jam nut into the shift rod. Thread the stud so that half of it protrudes from the other end of the shift rod. Thread both jam nuts onto the stud so that they are drawn up to the shift rod.

29. Thread the stud in the shift rod as far as it will go into the forward heim joint on the OEM shift knuckle.

30. Use nonpermanent thread locking agent and slide the M6 x 20mm socket head screw through the shift rod heim joint. Place the rod end collar on the M6 x 20mm screw between the heim joint and the shift lever. Tighten the screw hand tight with a 5mm hex tool.

31. Cover the left footpeg with a rag to protect the finish and lock a vise grips onto it. Use a 13mm open end wrench to tighten the bolt into the foot peg.

Adjusting Footrest Height

32. Sato rearsets can be adjusted to five different positions. All that needs to be done is to remove the two M8 x 15mm button head screws from the step plate and position them in the desired set of mounting holes. Apply nonpermanent thread locking agent to the screws before remounting them and tighten the screws with a 5mm hex tool socket and torque wrench.

Adjusting Brake Pedal Height and Length

33. If the brake pedal height requires adjusting, loosen the M6 x 25mm button head screws that fasten the heel guard and the rear brake master cylinderusing a 4mm hex tool. Loosen the jam nut on the master cylinder using a 12mm open end wrench and remove the brake rod pin from the brake pedal. Thread the brake rod up or down as required to attain the proper height.

If desired, the rear brake pedal length may also be adjusted at this time by attaching the pedal tip to a different hole in the front of the pedal. Use non permanent thread locking agent and tighten the pedal tip screw hand tight with a 4mm hex tool.

34. When a comfortable height is achieved in the brake pedal, lubricate the brake rod

pin with white lithium grease. Place the brake rod pin back through the brake pedal making sure the washer is in place between the the brake rod and the brake pedal. Apply nonpermanent thread locking agent to the M6 x 25mm screws that fasten the heel guard and rear brake master cylinder and torque the screws to 3 foot lbs using a 4mm hex tool socket. Tighten the lock nut against the brake rod with a 12mm open end wrench. Install the E clip to the groove in the end of the brake rod pin using a small screwdriver to press it into the groove.

Adjust Gear Shift Pedal Height

35. If it is determined that the gear shift pedal height need to be adjusted, use two 10mm open end wrenches to loosen the jam nut on both the forward and aft heim joints. turn the shift rod by hand to lengthen or shorten it. Tighten the jam nuts when the proper shift pedal height is achieved.

Final Tightening and Thread Locking Agent

36. Use a 5mm hex tool to remove the 8mm button head screw from the shift pedal and the foot peg bearing collar.

37. Remove the gear shift pedal tip and reposition it to another hole in the end of the pedal if a different reach is desired. Apply nonpermanent thread locking agent to the pedal tip screw and tighten it hand tight with a 4mm hex tool.

38. Apply nonpermanent thread locking agent to the gear shift pedal screw. Reassemble the shift lever, foot peg bearing collar and left step plate. Using a 5mm hex tool socket and torque wrench, torque the gear shift screw to 15 foot lbs.

Sato Rearsets Install

Sato Recomends fully installing their rearsets and then disassembling after the desired height adjustments are determined. Thread locking agent may then be applied to all bolts, including those in the parts which come preassembled. In this tutorial I suggest applying thread locking agent immediately upon installation unless the bolts need to be removed or loosened for adjustment purposes. In these cases, I have stated to not apply thread locking agent until the parts have been properly adjusted.

The torque specs in the Sato installation instructions are 7-8 foot pounds for the 6mm bolts. I found that the hex in the 6 mm button head bolts started to strip at around 5 foot pounds. I recommend using nonpermanent thread locking agent on these bolts and torquing to no more than 3 foot pounds or just hand tighten good and snug. Sato torque specs for the 8mm bolts is 16-17 foot pounds. I used 15 foot pounds on these and had no problems with stripping. Henceforth in my tutorial, I specify the torque value that I actually used or the term “hand tight†to provide final tightening information.

I suggest taking the following preliminary steps to help with adjusting the pedal height when reinstalling the footrest assemblies or installing the aftermarket footrest.

Photograph the left and OEM right footrests so that there will be a visual indicator of the height the gear shift lever and the rear brake pedal were adjusted to. This may be handy for reinstalling the OEM footrest or adjustment of a gear shift lever on aftermarket footrest assemblies.

Also photograph the the shift linkage rod for reference if the gear shift lever should need to be adjusted exactly as it was. You may mark the rod with a Sharpie marker to show exactly where the jam nuts were tightened to.

For the right OEM footrest assy removal, refer to step 11 for an explanation as to how the rear brake pedal adjustment may be marked.

Tools:

Sharpie marker

small flat blade screwdriver

needle nose pliers

4mm hex tool socket

6mm hex tool socket

Two 10mm open end wrenches

vise grips

12mm open end wrench

nonpermanent thread locking agent

5mm hex tool socket

12mm box end wrench

0-50 ft lb torque wrench

sandpaper

Electrical tape

Zip tie

13 mm open end wrench

sandpaper

rag

white lithium grease

Footrest Bracket Removal, Right Side

1. Turn the rear brake pedal joint pin so that the two bent over stems of the cotter pin are accessible. It will be easier to turn the pin if pressure is applied under the joint so that the joint is lifted slightly. Straighten the cotter pin stems using a small flat blade screwdriver and a needle nose pliers. Pull the cotter pin out of the joint pin.

2. There is a small washer on the joint pin to the inside of the joint. Remove the washer.

3. Push up under the master cylinder/brake pedal joint and remove the joint pin.

4. Remove the two bolts that fasten the master cylinder to the inside of the heel guard

using a 4mm hex tool.

5. Remove the footrest bracket using a 6mm hex tool.

6. Disconnect the rear brake light sensor wire by pressing the point on the tine in and pulling the connectors apart. Remove the right footrest assembly.

Footrest Bracket Removal, Left Side

7. Loosen the jam nut at the forward heim joint using a 10mm open end wrench.

8. Remove the 3 mounting bolts using a 6mm hex tool.

9. Turn the entire left footrest assembly counter clockwise to unthread the shift rod from the forward heim joint. Remove the left footrest assembly. The gear shift lever adjustment of the shift linkage rod is left unchanged for reinstallation.

Sato Rearset Install, Right (Brake Pedal)

10. Clamp a vise grips onto the joint at the bottom of the rear brake master cylinder as shown. Use a 12mm open end wrench to loosen the locknut.

Do not place a screwdriver through the pivot holes in the joint to brace the joint while loosening the jam nut. The side plates of the joint will bend from the twisting force. Vise grips are the way to go on this.

11. Remove the joint and the nut inside of it.

I used a Sharpie on the stud threads to mark the position of the locknut for reinstallation reference.

12. Place an 8mm socket head bolt through each of the two mounting holes in the right base plate. Place a spacer behind the base plate on the threads of each 8mm bolt.

13. Use nonpermanent threadlocking agent and install the right base plate to the frame using a 6mm hex tool socket. Torque base plate mounting bolts, 15 foot lbs.

14. The brake pedal and right foot peg are preassembled to the right step plate. Tighten the M6 x 20mm screw snug into the brake pedal tip with a 4mm hex tool. Do not apply thread locking agent.

15. Attach the right step plate (with foot peg and rear brake pedal installed) to the right base plate. Choose one of the height positions and thread the two 8 mm button head bolts into the proper holes. Tighten the two 8mm button head socket bolts snug with a 5mm hex tool. Do not apply thread locking agent.

16. Slide the two 6mm button head screws through the right heel guard and the right right step plate. Thread the screws into the holes of the rear brake master cylinder. Leave these screws loose for the time being.

The downspout from the rear brake reservoir will press up into the recess in the undertail.

17. Thread the rear brake rod onto the stud of the rear brake master cylinder. Make sure that the flat of the rear brake rod faces up at the locknut and the peg faces the rear brake pedal.

I placed the locknut at the same height as it had been tightened against the OEM pivot joint. I tightened the rear brake rod up to it.

18. Place the washer onto the rear brake rod peg and then place the peg through the hole at the back of the rear brake pedal. Use a 4mm hex tool to snug the the two 6mm bolts that fasten the heel guard and the master cylinder to the step plate. Use a 12mm open end wrench to tighten the lock nut against the rear brake rod. Do not install the E clip to the brake rod peg yet.

The stud on the rear brake master cylinder is mounted flexibly. The bottom end can be tilted in any direction to help fit the brake rod peg into the hole in the pedal. The heel guard/master cylinder bolts should also be loose while fitting the peg to the hole to allow some movement of the entire master cylinder.

Rear Brake Light Pressure sensor Switch

19. Drain the rear brake system (see https://www.hayabusa.org/forum/maintenance-do-yourself/170084-genii-front-rear-brake-fluid-clutch-fluid-bleed-drain.html, Introduction and steps 13-18) and remove the banjo bolt from the rear master cylinder using a 12mm box end wrench. Place the threads of the brake light pressure sensor switch through the brake line fitting with a washer on either side of the fitting. Thread the pressure sensor switch with washers and brake line fitting into the master cylinder. Tighten the pressure sensor switch. Torque rear brake master cylinder banjo bolt 16.5 foot lbs. Rout the wire into the tail up to the rear brake light wire as shown.

20. press the contact from each wire into the rear brake light connector lead. Either contact may go to either side of the connector regardless of polarity.

I sanded the contacts down a bit by rubbing them against sandpaper so they would fit into the connector smoothly.

21. Electrical tape the wires to the connector lead so they do not pull out. Zip tie the brake light pressure sensor switch wire to the frame as show. Fill and bleed the rear brake system with fresh brake fluid (see https://www.hayabusa.org/forum/maintenance-do-yourself/170084-genii-front-rear-brake-fluid-clutch-fluid-bleed-drain.html, Introduction and steps 13-21).

Sato Rearset Install, Left (shift pedal)

22. Install the left base plate to the frame using a 6mm hex tool and nonpermanent thread locking agent on the two M8 x 25mm socket head screws. Torque base plate mounting bolts, 15 foot lbs.

23. Install the shift pedal to the right kick plate. Place the foot peg bearing collar on the M8 x 35mm button head screw between the left step plate and the shift pedal. Use a 5mm hex tool hex tool to tighten the shift lever screw snug. Do not Use thread locking agent.

24. Fasten the shift pedal tip to the shift pedal. Tighten the M6 x 20mm screw snug using a 4mm hex tool. Do not use thread locking agent.

25. Assemble the foot peg, foot peg collar, lock washer and the M8 x 45mm bolt to the left kick plate as shown below. Use a 13 mm box end wrench to tighten the bolt snug.

26. Thread the M8 x 15mm button head screws through the left step plate and into the left base plate. snug them up with a 5mm hex tool.

27. Use a 4mm hex tool and non permanent thread locking agent to attach the left heel guard. Torque the heel guard screws to 3 foot lbs.

28. Assemble the reverse jam nut to the Sato heim joint by threading it all the way to the top of the threads. Thread the heim joint and jam nut into the shift rod. Thread the stud so that half of it protrudes from the other end of the shift rod. Thread both jam nuts onto the stud so that they are drawn up to the shift rod.

29. Thread the stud in the shift rod as far as it will go into the forward heim joint on the OEM shift knuckle.

30. Use nonpermanent thread locking agent and slide the M6 x 20mm socket head screw through the shift rod heim joint. Place the rod end collar on the M6 x 20mm screw between the heim joint and the shift lever. Tighten the screw hand tight with a 5mm hex tool.

31. Cover the left footpeg with a rag to protect the finish and lock a vise grips onto it. Use a 13mm open end wrench to tighten the bolt into the foot peg.

Adjusting Footrest Height

32. Sato rearsets can be adjusted to five different positions. All that needs to be done is to remove the two M8 x 15mm button head screws from the step plate and position them in the desired set of mounting holes. Apply nonpermanent thread locking agent to the screws before remounting them and tighten the screws with a 5mm hex tool socket and torque wrench.

Adjusting Brake Pedal Height and Length

33. If the brake pedal height requires adjusting, loosen the M6 x 25mm button head screws that fasten the heel guard and the rear brake master cylinderusing a 4mm hex tool. Loosen the jam nut on the master cylinder using a 12mm open end wrench and remove the brake rod pin from the brake pedal. Thread the brake rod up or down as required to attain the proper height.

If desired, the rear brake pedal length may also be adjusted at this time by attaching the pedal tip to a different hole in the front of the pedal. Use non permanent thread locking agent and tighten the pedal tip screw hand tight with a 4mm hex tool.

34. When a comfortable height is achieved in the brake pedal, lubricate the brake rod

pin with white lithium grease. Place the brake rod pin back through the brake pedal making sure the washer is in place between the the brake rod and the brake pedal. Apply nonpermanent thread locking agent to the M6 x 25mm screws that fasten the heel guard and rear brake master cylinder and torque the screws to 3 foot lbs using a 4mm hex tool socket. Tighten the lock nut against the brake rod with a 12mm open end wrench. Install the E clip to the groove in the end of the brake rod pin using a small screwdriver to press it into the groove.

Adjust Gear Shift Pedal Height

35. If it is determined that the gear shift pedal height need to be adjusted, use two 10mm open end wrenches to loosen the jam nut on both the forward and aft heim joints. turn the shift rod by hand to lengthen or shorten it. Tighten the jam nuts when the proper shift pedal height is achieved.

Final Tightening and Thread Locking Agent

36. Use a 5mm hex tool to remove the 8mm button head screw from the shift pedal and the foot peg bearing collar.

37. Remove the gear shift pedal tip and reposition it to another hole in the end of the pedal if a different reach is desired. Apply nonpermanent thread locking agent to the pedal tip screw and tighten it hand tight with a 4mm hex tool.

38. Apply nonpermanent thread locking agent to the gear shift pedal screw. Reassemble the shift lever, foot peg bearing collar and left step plate. Using a 5mm hex tool socket and torque wrench, torque the gear shift screw to 15 foot lbs.