card16969

Registered

So today on Aarons workshop were going to learn how to..... sorry I wanted to start out with a laugh. So that you dont think that im just some crack pot writing out some long summary of how to do a H.I.D. install heres a little about me. I spent over 4 years as a car audio installer installing not only stereo systems but remote starts, alarms, overhead and headrest video systems and many other vehicle electronics. Having been a avid motorcycle enthusiast and growing up around motorcycles I decided to pursue a career as a race mechanic, I attended Motorcycle Mechanics Institute in Phoenix Arizona and I graduated with honors and landed a job on a super bike team but unfortunately 2 months before I was supposed to move to work on the team the team lost its backing along with many other teams and I was out a job so here I am.

So a lot of people have a problem with their gauges and clock flickering after they install their H.I.D.'s. I have heard anything from the problem being electric noise to faulty lights to faulty gauges. In reality the issue is too high of an amperage draw on the lighting circuit. Simple way of figuring this out is look at the gauge of the wire being used to power the stock lighting. While the wattage of the lights may be equal to or greater than the wattage of the H.I.D.'s that are going to be used the amperage is greater. Some people are using delay timers in order to bypass this problem but that does not completely take care of it. The cause of the gauge flutter is that like any electric gauge of its type it has to learn its boundaries during start up and because it is on the same circuit as the lights when the H.I.D.'s fire up it draws too much amperage and shuts them down during their initial start up which causes them to flutter back and forth.

To properly take care of this issue we need to apply direct power to the ballast's and in order to do this we need to use a relay. For some people relays are intimidating but overall they are quite simple. The reason we use a separate power supply is because the circuit fot the lights is already quite full and we dont want to add the additional load. What we need to do this job is....

2x 4 post relays

in line fuse holder

wire strippers

pack of 8 female wire connectors sized to fit relay

zip ties

soldering gun and solder

electrical tape

4 colors of wire (preferably red and black heavier gauge wire and 2 other wire colors of your choice)

2 ring terminals

First we are going to start by removing the side fairings and then removing the nose/front fairing (you can do this install with it on the bike but i find it much easier to do with it off).

.

.

Next unplug the stock lights and ziptie back the wiring so that its neat and out of the way

Next you are going to install your bulbs into the appropriate locations

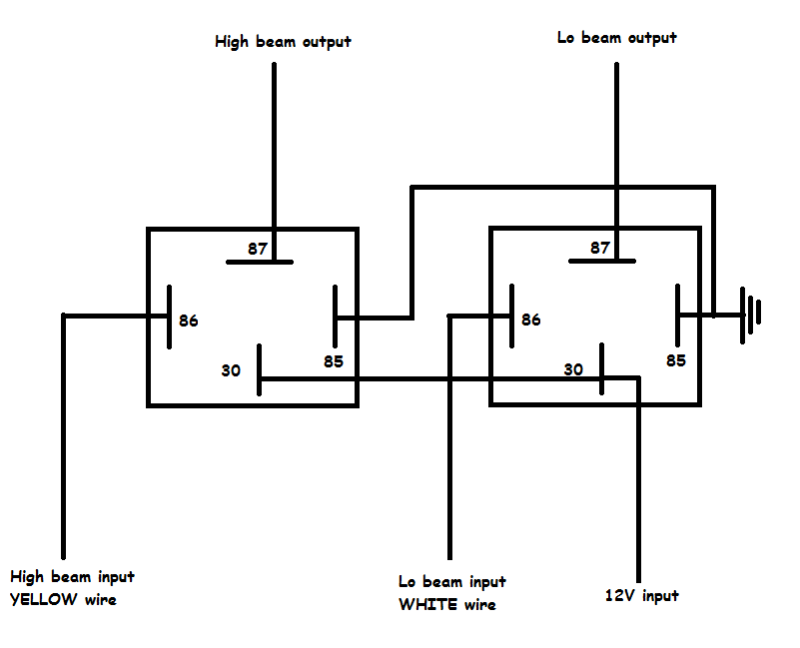

Next we are going to wire our relays using the following diagram

Take both wiring harness's from the ballasts and connect them to the ballast and cut off the opposite ends so it looks like this.

Next cut an approximately 3' long piece of red and piece of black wire and an additional 3" piece of both wires, these wires need to be heavier gauge because they are the power inputs for eveyr thing. These are going to be your power and your ground going to your relay . You are going to strip both ends of all four pieces of wire. Take the three inch piece of wire and the 3' piece of wire and place them together into one female connector and duplicate this for the other color of wire. These are going to be your power and ground jumper wires to power both relays. On the other end of the 3" piece of black wire place both ground wires from the power harness for the ballast and crimp them into another female connector. On the other end of the red wire you are going to crimp another female connector on. On both of the red wires coming from the ballast you are going to crimp on female connectors. The finished product should look like this.

Next tape both relays together so they look like this.

Now we are going to build our relay. DO NOT SOLDER THE WIRES DIRECTLY TO THE RELAY AS IT WILL DESTROY THE INTERNALS OF IT. Take the ground jumper (black) we made and connect each connector to post 85 on both relays. Now take the long red juper we buit and connect each connector to post 30 on each relay. Next take the red wire from each ballast and connect it to post 87 on each relay. This wire is the power wire going out to each ballast. Next you are going to create the trigger wire for each relay. These wires will power on the high or low beam. When running this wire you have to make sure that if it is the low beam input that you connect that ballast to the low beam bulb. Take your two remaining colors of wire and make approximately 3' pieces strip back one end of each wire and crimp on a female connector and connect on to the 86 post on each relay. When it is done it should look like this.

Now we are going to separate the wires, take the red and black heavier gauge wires and separate them. I put a piece of electircal tape about every 8" to tie them together and keep things nice and clean. now the power and ground wires that go to one ballast and the input wire that we made for that relay should be separated to one side and the other ballast to the other side so it looks like this.

Now we are going to use some tape or zip ties along the wires and clean them up. Around the relays, I place a good layer of electrical tape so that the wires stand no chance of coming off of the relay with the vibration of the bike. As your doing this it should look like this.

Next connect the ballasts to the bulbs and run the inputs along the nose and around the light fixture. Run it along the stock wiring harness as it makes for a clean install. Run the wires down and along the stock wiring until you are near the plug. Strip back the electrical tape and you wil find a white wire and a yellow wire. Strip back a piece of both of these wires as they are the inputs for your relay. Connect the wire coming from your low beam ballast to the WHITE wire and solder it and once it has cooled wrap it good with electrical tape and do the same connecting the wire for the high beam ballast to the YELLOW wire. Go along and clean up your wiring and zip tie it together where necessary. When you are finished the final install should look something like this.

Reinstall front fairing on bike and zip tie ballasts right air intake runner. Run the power and ground wires back to the battery. Trim the ground cable to the appropriate length and attach ring terminal. Take the power wire and trim accordingly, attach fuse holder and solder the wires and tape or heat shrink it. Attach ring terminal to the end and now connect negative and positive to the battery. Fire up the bike and test our your lights. If you have done everything your lights should work.

So a lot of people have a problem with their gauges and clock flickering after they install their H.I.D.'s. I have heard anything from the problem being electric noise to faulty lights to faulty gauges. In reality the issue is too high of an amperage draw on the lighting circuit. Simple way of figuring this out is look at the gauge of the wire being used to power the stock lighting. While the wattage of the lights may be equal to or greater than the wattage of the H.I.D.'s that are going to be used the amperage is greater. Some people are using delay timers in order to bypass this problem but that does not completely take care of it. The cause of the gauge flutter is that like any electric gauge of its type it has to learn its boundaries during start up and because it is on the same circuit as the lights when the H.I.D.'s fire up it draws too much amperage and shuts them down during their initial start up which causes them to flutter back and forth.

To properly take care of this issue we need to apply direct power to the ballast's and in order to do this we need to use a relay. For some people relays are intimidating but overall they are quite simple. The reason we use a separate power supply is because the circuit fot the lights is already quite full and we dont want to add the additional load. What we need to do this job is....

2x 4 post relays

in line fuse holder

wire strippers

pack of 8 female wire connectors sized to fit relay

zip ties

soldering gun and solder

electrical tape

4 colors of wire (preferably red and black heavier gauge wire and 2 other wire colors of your choice)

2 ring terminals

First we are going to start by removing the side fairings and then removing the nose/front fairing (you can do this install with it on the bike but i find it much easier to do with it off).

Next unplug the stock lights and ziptie back the wiring so that its neat and out of the way

Next you are going to install your bulbs into the appropriate locations

Next we are going to wire our relays using the following diagram

Take both wiring harness's from the ballasts and connect them to the ballast and cut off the opposite ends so it looks like this.

Next cut an approximately 3' long piece of red and piece of black wire and an additional 3" piece of both wires, these wires need to be heavier gauge because they are the power inputs for eveyr thing. These are going to be your power and your ground going to your relay . You are going to strip both ends of all four pieces of wire. Take the three inch piece of wire and the 3' piece of wire and place them together into one female connector and duplicate this for the other color of wire. These are going to be your power and ground jumper wires to power both relays. On the other end of the 3" piece of black wire place both ground wires from the power harness for the ballast and crimp them into another female connector. On the other end of the red wire you are going to crimp another female connector on. On both of the red wires coming from the ballast you are going to crimp on female connectors. The finished product should look like this.

Next tape both relays together so they look like this.

Now we are going to build our relay. DO NOT SOLDER THE WIRES DIRECTLY TO THE RELAY AS IT WILL DESTROY THE INTERNALS OF IT. Take the ground jumper (black) we made and connect each connector to post 85 on both relays. Now take the long red juper we buit and connect each connector to post 30 on each relay. Next take the red wire from each ballast and connect it to post 87 on each relay. This wire is the power wire going out to each ballast. Next you are going to create the trigger wire for each relay. These wires will power on the high or low beam. When running this wire you have to make sure that if it is the low beam input that you connect that ballast to the low beam bulb. Take your two remaining colors of wire and make approximately 3' pieces strip back one end of each wire and crimp on a female connector and connect on to the 86 post on each relay. When it is done it should look like this.

Now we are going to separate the wires, take the red and black heavier gauge wires and separate them. I put a piece of electircal tape about every 8" to tie them together and keep things nice and clean. now the power and ground wires that go to one ballast and the input wire that we made for that relay should be separated to one side and the other ballast to the other side so it looks like this.

Now we are going to use some tape or zip ties along the wires and clean them up. Around the relays, I place a good layer of electrical tape so that the wires stand no chance of coming off of the relay with the vibration of the bike. As your doing this it should look like this.

Next connect the ballasts to the bulbs and run the inputs along the nose and around the light fixture. Run it along the stock wiring harness as it makes for a clean install. Run the wires down and along the stock wiring until you are near the plug. Strip back the electrical tape and you wil find a white wire and a yellow wire. Strip back a piece of both of these wires as they are the inputs for your relay. Connect the wire coming from your low beam ballast to the WHITE wire and solder it and once it has cooled wrap it good with electrical tape and do the same connecting the wire for the high beam ballast to the YELLOW wire. Go along and clean up your wiring and zip tie it together where necessary. When you are finished the final install should look something like this.

Reinstall front fairing on bike and zip tie ballasts right air intake runner. Run the power and ground wires back to the battery. Trim the ground cable to the appropriate length and attach ring terminal. Take the power wire and trim accordingly, attach fuse holder and solder the wires and tape or heat shrink it. Attach ring terminal to the end and now connect negative and positive to the battery. Fire up the bike and test our your lights. If you have done everything your lights should work.

i just know that i love my hids and they work perfectly without the extra wiring and acc. oh and i also run air ride, leds, digital volt gauge, digital psi gauge. battery is a fastbygast pb2 380 ca batt. stock stator.

i just know that i love my hids and they work perfectly without the extra wiring and acc. oh and i also run air ride, leds, digital volt gauge, digital psi gauge. battery is a fastbygast pb2 380 ca batt. stock stator. just removed the gauges and inner fairing covers. not being a smarta$$ but just sounds like more than needed for a set of lights. in my opinion if you honestly feel you have 2 do all that and worry about eletrical gremlins or ur just not eletrically inclined, just leav it alone. u dont want an electrical headache. just my 2cents

just removed the gauges and inner fairing covers. not being a smarta$$ but just sounds like more than needed for a set of lights. in my opinion if you honestly feel you have 2 do all that and worry about eletrical gremlins or ur just not eletrically inclined, just leav it alone. u dont want an electrical headache. just my 2cents