Mythos

Registered

Brake and Clutch Fluid Bleed and Drain

The brake fluid in brake and clutch systems is bled primarily to to rid the system of air that may have entered the system during maintenance procedures. Fluid may also be bled in order to change old, worn out brake fluid for new. In this case, the system is not drained but fresh fluid is added while the system is being bled. Proportionally, only a small amount of the old fluid remains with the fresh fluid.

In some situations (such as removing brake lines) it is desirable to drain all fluid from the system. The fluid may be purged completely simply by bleeding the system without replenishing it. In this case, the fluid in the system is displaced by air. The system will need to be refilled with new fluid and thoroughly bled until all air is eliminated from the system.

Air can be compressed much easier than brake fluid so the presence of air anywhere within a brake system reduces the internal pressure that is built when brakes are applied. Without maximum brake fluid pressure, the moving parts within the brake system will lack force which results in a loss of braking power. Air within the brake system will be notable by what is often called a “spongy†feel to the brake lever or pedal. Spongy brakes feel soft and the lever actuates more than usual.

Any small amount of water is also undesirable to have trapped within the system. Water does not react to compression like brake fluid and it will overheat at a lower temperature. Be careful to keep any water that might be used to wash a brake fluid spill from entering the system. Dust and dirt particles can contribute to clogs in the systems so take measures to prevent them from entering the the system through an open reservoir.

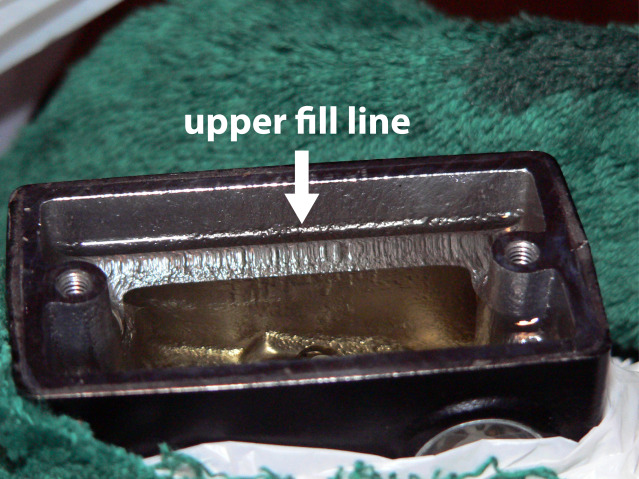

Fill fluid reservoirs to just below the maximum full line and NO HIGHER. Overfilling the reservoir can result in an excessive volume when the fluid gets hot and expands from application of the brake. Excessive volume may cause brakes to lock without warning. Excessive internal fluid may also cause fluid leakage.

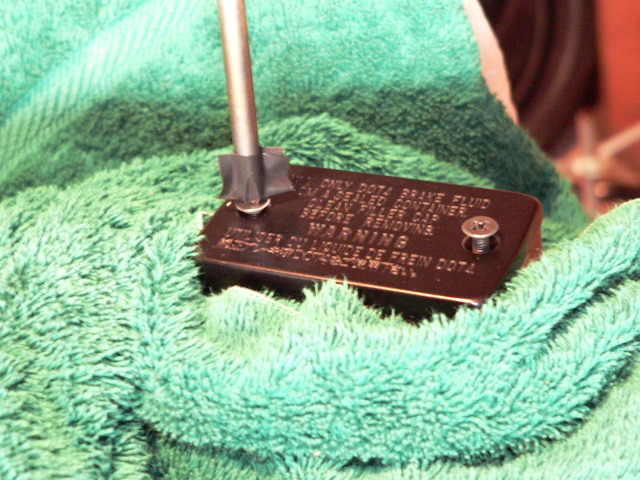

DOT #4 is the grade of brake fluid that is recommended for the Hayabusas brake system. Brake fluids that are labeled for use in systems requiring “DOT #3 or DOT #4†are actually no different than those specifically labeled for use in systems requiring DOT #4. DOT #5 is a higher performance break fluid with a higher boiling point but if DOT #5 is used in systems designed for DOT #4, the fluid may leak past the rubber seals.

Brake fluid will etch many painted or plastic surfaces that it comes in contact with. Therefore, a pail of water and sponge should be kept prepared for the inevitable drips and spills that occur while working with the brake and clutch fluid systems. It is always wise to cover as much of the bike as possible with plastic to prevent damage from spatters that may occur without having been detected.

The pictures in this tutorial show the body panels and some other parts removed for ease of viewing. It’s not necessary to remove these parts although if they are removed, they are safe from potential brake/clutch fluid spills.

Tools:

pail of water and sponge

plastic

8mm box end wrench

1/4†clear plastic hose

empty bottle.

towel

phillips screwdriver

electrical tape

fresh brake fluid

vacuum pump tool

Front Brake Bleed

Set the bike vertical on a rear stand to avoid fluid spills.

1. Cover the entire front of the motorcycle with plastic to protect painted and plastic

surfaces from accidental spills and spatters of brake fluid. Leave the front brake fluid reservoir uncovered by the plastic.

2. Remove the rubber cap from the front brake bleed valve located on the right front brake caliper.

I wrapped a piece of tape around the hex on the bleed valve to protect the finish from the wrench (see next step).

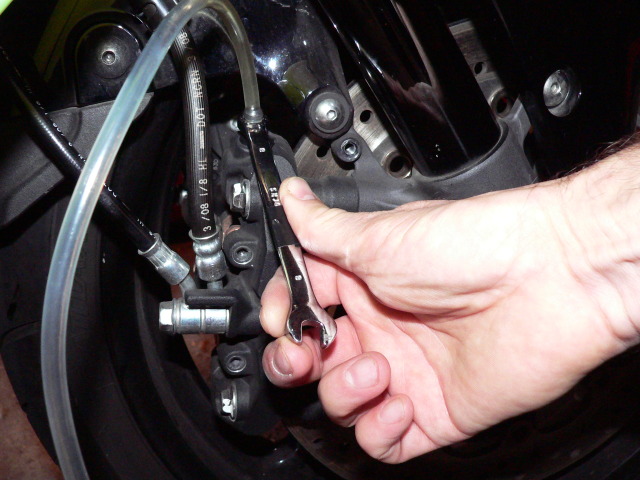

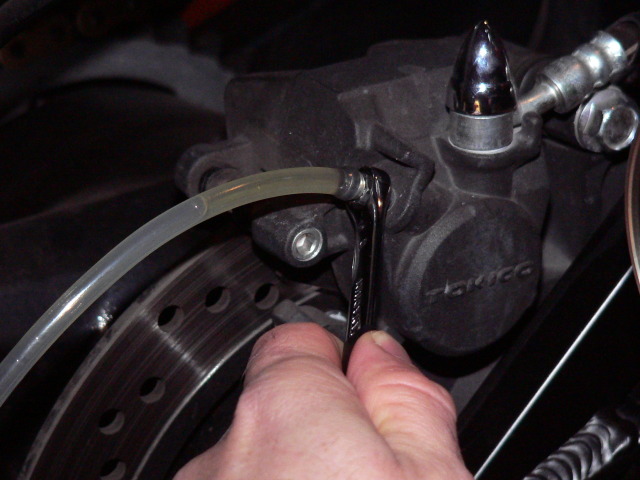

3. Place an 8mm box end wrench on the bleed valve of the right front brake caliper. Slide a 1/4†clear plastic hose over the nipple on the bleed valve and place the other end of the hose into an empty bottle.

Quarter inch O.D. plastic hose that is used for water tubing on refrigerators works well for bleed hose.

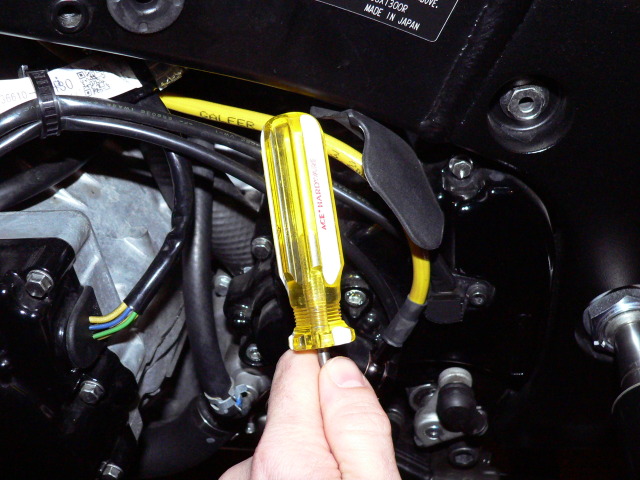

4. Place a towel around the front brake fluid reservoir. Use a phillips screwdriver to remove the the two screws that fasten the front brake fluid reservoir cover.

I stretch a piece of electrical tape over the tip of the screwdriver to prevent damage to the finish on the screws.

5. Remove the internal front brake fluid reservoir cover.

6. Remove the rubber gasket from the front brake fluid reservoir.

7. Slowly actuate the front brake lever, pumping if necessary to build pressure in the system. Watch for air bubbles rising to the top of the reservoir fluid. Hold the lever pressed.

It’s possible for fluid to squirt out. To be careful, slowly pump the lever.

Watch for tiny air bubbles rising rising in the reservoir when the brake is pumped. When they stop, the master cylinder is bled but more air may be trapped lower in the system. To remove all air, continue to bleed as described below.

8. While squeezing the brake lever, turn the bleed valve one quarter turn counterclockwise. Squeeze the brake lever to the grip and hold to express fluid. Watch for air bubbles in the hose. Turn the bleed valve closed again. Release the brake lever.

9. Tap the brake lines and master cylinder with a solid object to dislodge any air bubbles that may be clinging to the inside of the system. Continue bleeding.

10. Repeat steps 7-9 four or five more times. The process is: squeeze/pump lever, open bleed, close bleed, release lever.

squeeze, open, close, release...squeeze, open, close, release...

If bleeding is not performed in this order, air can be sucked back into the system rather than removed.

Do not allow the fluid to level to fall to the bottom of the reservoir or air will be sucked into the master cylinder. Replenish the brake fluid by pouring fresh fluid into the reservoir. Continue bleeding until the fluid comes out colorless (old fluid is red-brown).

While air is bled from the system, watch for air bubbles in the fluid that is expressed through the hose.

Continue bleeding the system until the fluid is colorless and clear of air.

11. Repeat steps 7-10 on the left front brake caliper and the front brake system should be completely bled of air.

12. When the system is bled of air, fill the the fluid reservoir to just below the upper fill line (never fill the fluid reservoir higher than the fill line) and install the reservoir gasket and inner and outer covers(reverse procedure of steps 4-6).

Remove the plastic tubing from the air bleeder valve, install the bleed cover and tighten the bleed valve(s).

Front bleed valves tightening torque: 5.5 ftlbs.

I do not tighten the delicate threads on the bleeds quite that much. Approximately 4 ft pounds is good and carefully check for signs of leakage from the bleeds immediately after a test ride with hard braking.

Rear Brake Bleed

Set the bike vertical on a rear stand to avoid fluid spills.

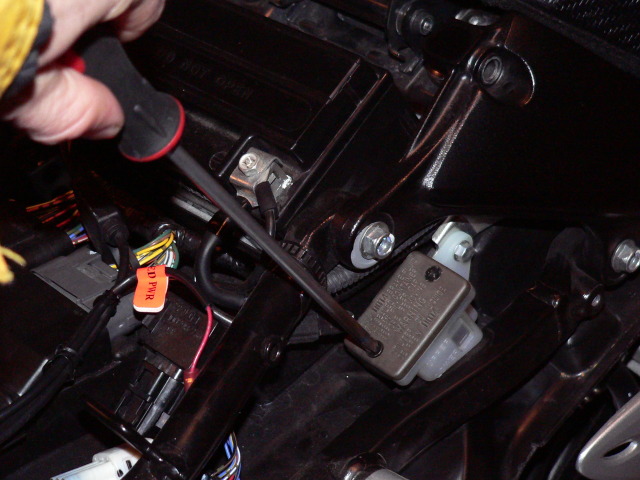

Remove the frame cover from the tail of the bike.

Plastic and a towel may be placed over the surrounding area to protect against possible spatters of brake fluid from the reservoir under the tail frame cover.

13. Remove the bleed valve cap.

14. Place an 8mm wrench on the bleed valve. Attach a length of 1/4 inch tubing to the bleed valve and place the opposite end in a receptacle.

15. Use a phillips screwdriver to remove the two screws from the reservoir cover of the rear brake fluid reservoir. Remove the reservoir cover.

16. Remove the gasket from the rear brake reservoir.

17. Pump the rear brake pedal and hold it down.

Watch the reservoir for any tiny air bubbles that might rise to the surface of the fluid. If bubbles are observed, continue pumping. When the bubbles stop, the rear brake master cylinder is bled of air. The lower end of the system still needs to be bled.

18. While holding the rear brake pedal down, open the rear brake bleed valve one quarter turn. Press the brake pedal to the bottom of its throw as brake pressure is eliminated and fluid is expressed from the bleed valve. Watch for air bubbles in the hose. While still holding the rear brake pedal all the way down, turn the the bleed valve closed. Allow the rear brake pedal to return back to the top position.

19. Tap the brake lines and master cylinder with a solid object to dislodge any air bubbles that may be clinging to the inside of the system. Continue bleeding.

20. Repeat steps 18-19 four or five more times. The process is: squeeze/pump lever, open bleed, close bleed, release lever...

squeeze, open, close, release... squeeze, open, close, release...

If the bleed is not performed in this order, air or old fluid from the receptacle can be sucked back into the system rather than removed.

Do not allow the fluid to level to fall to the bottom of the reservoir or air will be sucked into the master cylinder from the empty reservoir. Replenish the brake fluid by pouring fresh fluid into the reservoir as you bleed.

Continue bleeding and replenishing fluid as described above. As the system is bled, watch for air bubbles in the fluid that is expressed through the plastic hose attached to the bleed valve.

Continue bleeding the system until the fluid is colorless and clear of air.

21. When the system is bled of air, fill the the fluid reservoir to the upper fill line (never fill the fluid reservoir higher than the upper fill line) and install the reservoir gasket and cover (reverse procedure of steps 14-15). Remove the plastic tubing from the air bleeder valve, install the bleed cover and tighten the rear bleed valve.

Rear brake bleed valves tightening torque: 5.5 ft lbs.

I do not tighten the delicate threads on the bleeds quite that much. Approximately 4 ft pounds is good and carefully check for signs of leakage from the bleeds immediately after a test ride with hard braking.

Clutch Line Bleed

Set the bike vertical on a rear stand to avoid fluid spills.

22. Cover the entire front of the motorcycle with plastic to protect painted and plastic

surfaces from accidental spills and spatters of brake fluid. Leave the clutch fluid reservoir uncovered by the plastic.

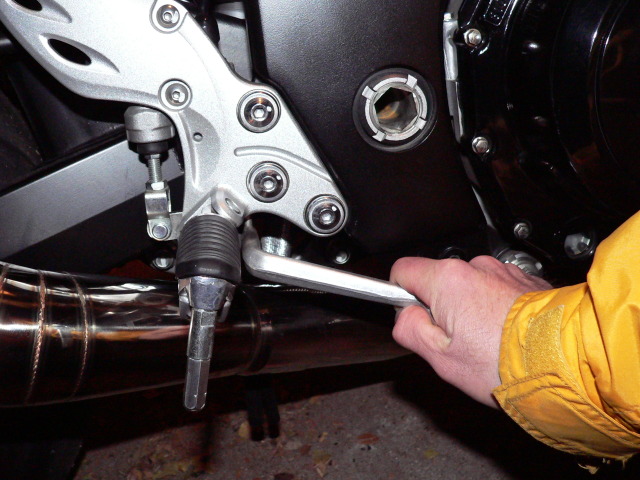

23. Remove the rubber cap from the clutch slave bleed valve.

I wrapped a piece of tape around the hex on the bleed valve to protect the finish from the wrench (see next step).

24. Place an 8mm box end wrench on the clutch slave bleed valve. Slide a 1/4†clear plastic hose over the nipple on the bleed valve and place the other end of the hose into an empty bottle or other receptacle.

Quarter inch O.D. plastic hose that is used for water tubing on refrigerators works well for bleed hose.

25. Place a towel around the clutch fluid reservoir. Use a phillips screwdriver to remove the the two screws that fasten the front brake fluid reservoir cover.

I stretch a piece of electrical tape over the tip of the screwdriver to prevent damage to the finish on the screws.

26. Remove the internal clutch fluid reservoir cover.

27. Remove the rubber gasket from the clutch fluid reservoir.

28. Slowly actuate the clutch lever, pumping the lever. Watch for air bubbles rising to the top of the reservoir fluid. Hold the lever to the grip.

It’s possible for fluid to squirt out. To be careful, slowly pump the lever.

You might see tiny air bubbles rising in the reservoir when the clutch is pumped. If you see this, pump the clutch lever until the bubbles stop. The master cylinder is now bled but more air may be trapped lower in the system. To remove all air, continue to bleed as described below.

29. While holding the clutch lever to the grip, turn the bleed valve one quarter turn counterclockwise. Fluid will flow through the hose connected to the bleed valve. Watch for air bubbles in the hose. Turn the bleed valve closed again. Release the clutch lever.

30. Tap the clutch slave cylinder, lines and master cylinder with a solid object to dislodge any air bubbles that may be clinging to the inside of the system. Continue bleeding.

31. Repeat steps 28-30 four or five more times. The process is: squeeze/pump lever, open bleed, close bleed, release lever.

squeeze, open, close, release...squeeze, open, close, release...

If the bleed is not performed in this order, air can be sucked back into the system rather than removed.

Do not allow the fluid to level to fall to the bottom of the reservoir or air will be sucked into the master cylinder. Replenish the clutch fluid by pouring fresh fluid into the reservoir. Continue bleeding until the fluid comes out colorless (old fluid is red-brown).

When air is bled from the system, watch for air bubbles in the fluid that is expressed through the hose.

Continue bleeding the system until the fluid is colorless and clear of air.

32. When the system is bled of air, fill the the fluid reservoir to just below the fill mark (never fill the fluid reservoir higher than the fill mark) and install the reservoir gasket and inner and outer covers(reverse procedure of steps 25-27).

Remove the plastic tubing from the air bleeder valve, install the bleed cover and tighten the bleed valve(s).

Clutch slave bleed valve tightening torque: 4.5 ftlbs.

I do not tighten the delicate threads on the bleeds quite that much. Approximately 4 ft pounds is good and carefully check for signs of leakage from the bleeds immediately after a test ride.

The brake fluid in brake and clutch systems is bled primarily to to rid the system of air that may have entered the system during maintenance procedures. Fluid may also be bled in order to change old, worn out brake fluid for new. In this case, the system is not drained but fresh fluid is added while the system is being bled. Proportionally, only a small amount of the old fluid remains with the fresh fluid.

In some situations (such as removing brake lines) it is desirable to drain all fluid from the system. The fluid may be purged completely simply by bleeding the system without replenishing it. In this case, the fluid in the system is displaced by air. The system will need to be refilled with new fluid and thoroughly bled until all air is eliminated from the system.

Air can be compressed much easier than brake fluid so the presence of air anywhere within a brake system reduces the internal pressure that is built when brakes are applied. Without maximum brake fluid pressure, the moving parts within the brake system will lack force which results in a loss of braking power. Air within the brake system will be notable by what is often called a “spongy†feel to the brake lever or pedal. Spongy brakes feel soft and the lever actuates more than usual.

Any small amount of water is also undesirable to have trapped within the system. Water does not react to compression like brake fluid and it will overheat at a lower temperature. Be careful to keep any water that might be used to wash a brake fluid spill from entering the system. Dust and dirt particles can contribute to clogs in the systems so take measures to prevent them from entering the the system through an open reservoir.

Fill fluid reservoirs to just below the maximum full line and NO HIGHER. Overfilling the reservoir can result in an excessive volume when the fluid gets hot and expands from application of the brake. Excessive volume may cause brakes to lock without warning. Excessive internal fluid may also cause fluid leakage.

DOT #4 is the grade of brake fluid that is recommended for the Hayabusas brake system. Brake fluids that are labeled for use in systems requiring “DOT #3 or DOT #4†are actually no different than those specifically labeled for use in systems requiring DOT #4. DOT #5 is a higher performance break fluid with a higher boiling point but if DOT #5 is used in systems designed for DOT #4, the fluid may leak past the rubber seals.

Brake fluid will etch many painted or plastic surfaces that it comes in contact with. Therefore, a pail of water and sponge should be kept prepared for the inevitable drips and spills that occur while working with the brake and clutch fluid systems. It is always wise to cover as much of the bike as possible with plastic to prevent damage from spatters that may occur without having been detected.

The pictures in this tutorial show the body panels and some other parts removed for ease of viewing. It’s not necessary to remove these parts although if they are removed, they are safe from potential brake/clutch fluid spills.

Tools:

pail of water and sponge

plastic

8mm box end wrench

1/4†clear plastic hose

empty bottle.

towel

phillips screwdriver

electrical tape

fresh brake fluid

vacuum pump tool

Front Brake Bleed

Set the bike vertical on a rear stand to avoid fluid spills.

1. Cover the entire front of the motorcycle with plastic to protect painted and plastic

surfaces from accidental spills and spatters of brake fluid. Leave the front brake fluid reservoir uncovered by the plastic.

2. Remove the rubber cap from the front brake bleed valve located on the right front brake caliper.

I wrapped a piece of tape around the hex on the bleed valve to protect the finish from the wrench (see next step).

3. Place an 8mm box end wrench on the bleed valve of the right front brake caliper. Slide a 1/4†clear plastic hose over the nipple on the bleed valve and place the other end of the hose into an empty bottle.

Quarter inch O.D. plastic hose that is used for water tubing on refrigerators works well for bleed hose.

4. Place a towel around the front brake fluid reservoir. Use a phillips screwdriver to remove the the two screws that fasten the front brake fluid reservoir cover.

I stretch a piece of electrical tape over the tip of the screwdriver to prevent damage to the finish on the screws.

5. Remove the internal front brake fluid reservoir cover.

6. Remove the rubber gasket from the front brake fluid reservoir.

7. Slowly actuate the front brake lever, pumping if necessary to build pressure in the system. Watch for air bubbles rising to the top of the reservoir fluid. Hold the lever pressed.

It’s possible for fluid to squirt out. To be careful, slowly pump the lever.

Watch for tiny air bubbles rising rising in the reservoir when the brake is pumped. When they stop, the master cylinder is bled but more air may be trapped lower in the system. To remove all air, continue to bleed as described below.

8. While squeezing the brake lever, turn the bleed valve one quarter turn counterclockwise. Squeeze the brake lever to the grip and hold to express fluid. Watch for air bubbles in the hose. Turn the bleed valve closed again. Release the brake lever.

9. Tap the brake lines and master cylinder with a solid object to dislodge any air bubbles that may be clinging to the inside of the system. Continue bleeding.

10. Repeat steps 7-9 four or five more times. The process is: squeeze/pump lever, open bleed, close bleed, release lever.

squeeze, open, close, release...squeeze, open, close, release...

If bleeding is not performed in this order, air can be sucked back into the system rather than removed.

Do not allow the fluid to level to fall to the bottom of the reservoir or air will be sucked into the master cylinder. Replenish the brake fluid by pouring fresh fluid into the reservoir. Continue bleeding until the fluid comes out colorless (old fluid is red-brown).

While air is bled from the system, watch for air bubbles in the fluid that is expressed through the hose.

Continue bleeding the system until the fluid is colorless and clear of air.

11. Repeat steps 7-10 on the left front brake caliper and the front brake system should be completely bled of air.

12. When the system is bled of air, fill the the fluid reservoir to just below the upper fill line (never fill the fluid reservoir higher than the fill line) and install the reservoir gasket and inner and outer covers(reverse procedure of steps 4-6).

Remove the plastic tubing from the air bleeder valve, install the bleed cover and tighten the bleed valve(s).

Front bleed valves tightening torque: 5.5 ftlbs.

I do not tighten the delicate threads on the bleeds quite that much. Approximately 4 ft pounds is good and carefully check for signs of leakage from the bleeds immediately after a test ride with hard braking.

Rear Brake Bleed

Set the bike vertical on a rear stand to avoid fluid spills.

Remove the frame cover from the tail of the bike.

Plastic and a towel may be placed over the surrounding area to protect against possible spatters of brake fluid from the reservoir under the tail frame cover.

13. Remove the bleed valve cap.

14. Place an 8mm wrench on the bleed valve. Attach a length of 1/4 inch tubing to the bleed valve and place the opposite end in a receptacle.

15. Use a phillips screwdriver to remove the two screws from the reservoir cover of the rear brake fluid reservoir. Remove the reservoir cover.

16. Remove the gasket from the rear brake reservoir.

17. Pump the rear brake pedal and hold it down.

Watch the reservoir for any tiny air bubbles that might rise to the surface of the fluid. If bubbles are observed, continue pumping. When the bubbles stop, the rear brake master cylinder is bled of air. The lower end of the system still needs to be bled.

18. While holding the rear brake pedal down, open the rear brake bleed valve one quarter turn. Press the brake pedal to the bottom of its throw as brake pressure is eliminated and fluid is expressed from the bleed valve. Watch for air bubbles in the hose. While still holding the rear brake pedal all the way down, turn the the bleed valve closed. Allow the rear brake pedal to return back to the top position.

19. Tap the brake lines and master cylinder with a solid object to dislodge any air bubbles that may be clinging to the inside of the system. Continue bleeding.

20. Repeat steps 18-19 four or five more times. The process is: squeeze/pump lever, open bleed, close bleed, release lever...

squeeze, open, close, release... squeeze, open, close, release...

If the bleed is not performed in this order, air or old fluid from the receptacle can be sucked back into the system rather than removed.

Do not allow the fluid to level to fall to the bottom of the reservoir or air will be sucked into the master cylinder from the empty reservoir. Replenish the brake fluid by pouring fresh fluid into the reservoir as you bleed.

Continue bleeding and replenishing fluid as described above. As the system is bled, watch for air bubbles in the fluid that is expressed through the plastic hose attached to the bleed valve.

Continue bleeding the system until the fluid is colorless and clear of air.

21. When the system is bled of air, fill the the fluid reservoir to the upper fill line (never fill the fluid reservoir higher than the upper fill line) and install the reservoir gasket and cover (reverse procedure of steps 14-15). Remove the plastic tubing from the air bleeder valve, install the bleed cover and tighten the rear bleed valve.

Rear brake bleed valves tightening torque: 5.5 ft lbs.

I do not tighten the delicate threads on the bleeds quite that much. Approximately 4 ft pounds is good and carefully check for signs of leakage from the bleeds immediately after a test ride with hard braking.

Clutch Line Bleed

Set the bike vertical on a rear stand to avoid fluid spills.

22. Cover the entire front of the motorcycle with plastic to protect painted and plastic

surfaces from accidental spills and spatters of brake fluid. Leave the clutch fluid reservoir uncovered by the plastic.

23. Remove the rubber cap from the clutch slave bleed valve.

I wrapped a piece of tape around the hex on the bleed valve to protect the finish from the wrench (see next step).

24. Place an 8mm box end wrench on the clutch slave bleed valve. Slide a 1/4†clear plastic hose over the nipple on the bleed valve and place the other end of the hose into an empty bottle or other receptacle.

Quarter inch O.D. plastic hose that is used for water tubing on refrigerators works well for bleed hose.

25. Place a towel around the clutch fluid reservoir. Use a phillips screwdriver to remove the the two screws that fasten the front brake fluid reservoir cover.

I stretch a piece of electrical tape over the tip of the screwdriver to prevent damage to the finish on the screws.

26. Remove the internal clutch fluid reservoir cover.

27. Remove the rubber gasket from the clutch fluid reservoir.

28. Slowly actuate the clutch lever, pumping the lever. Watch for air bubbles rising to the top of the reservoir fluid. Hold the lever to the grip.

It’s possible for fluid to squirt out. To be careful, slowly pump the lever.

You might see tiny air bubbles rising in the reservoir when the clutch is pumped. If you see this, pump the clutch lever until the bubbles stop. The master cylinder is now bled but more air may be trapped lower in the system. To remove all air, continue to bleed as described below.

29. While holding the clutch lever to the grip, turn the bleed valve one quarter turn counterclockwise. Fluid will flow through the hose connected to the bleed valve. Watch for air bubbles in the hose. Turn the bleed valve closed again. Release the clutch lever.

30. Tap the clutch slave cylinder, lines and master cylinder with a solid object to dislodge any air bubbles that may be clinging to the inside of the system. Continue bleeding.

31. Repeat steps 28-30 four or five more times. The process is: squeeze/pump lever, open bleed, close bleed, release lever.

squeeze, open, close, release...squeeze, open, close, release...

If the bleed is not performed in this order, air can be sucked back into the system rather than removed.

Do not allow the fluid to level to fall to the bottom of the reservoir or air will be sucked into the master cylinder. Replenish the clutch fluid by pouring fresh fluid into the reservoir. Continue bleeding until the fluid comes out colorless (old fluid is red-brown).

When air is bled from the system, watch for air bubbles in the fluid that is expressed through the hose.

Continue bleeding the system until the fluid is colorless and clear of air.

32. When the system is bled of air, fill the the fluid reservoir to just below the fill mark (never fill the fluid reservoir higher than the fill mark) and install the reservoir gasket and inner and outer covers(reverse procedure of steps 25-27).

Remove the plastic tubing from the air bleeder valve, install the bleed cover and tighten the bleed valve(s).

Clutch slave bleed valve tightening torque: 4.5 ftlbs.

I do not tighten the delicate threads on the bleeds quite that much. Approximately 4 ft pounds is good and carefully check for signs of leakage from the bleeds immediately after a test ride.