Redcurbjumper

Registered

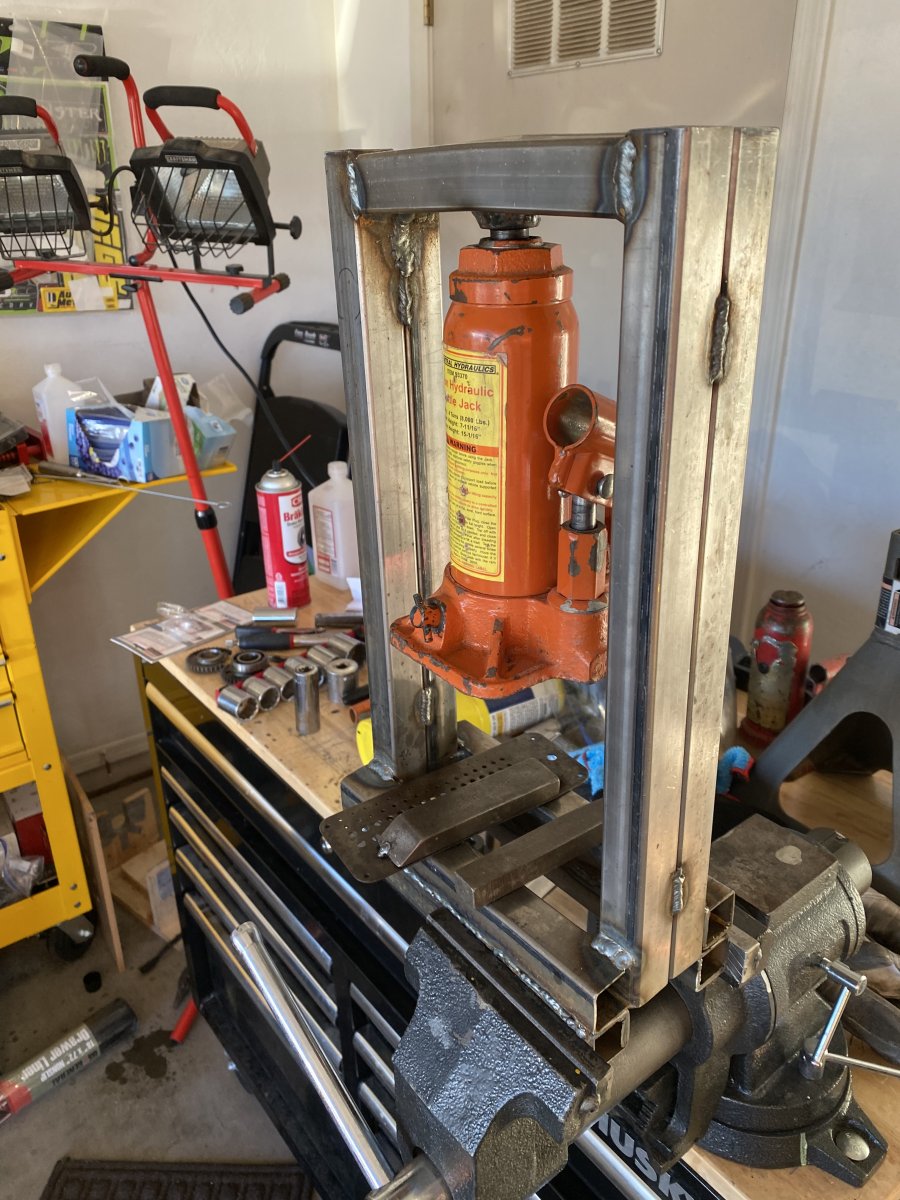

Pressed the stock gears and bearings off and installed the adjustable gears and new bearings with this today. Could have used some more bracing as she started to bend a little right when the stock gears broke free (heat was used). Square tubing and an old bottle Jack. (Bird poop welds are patent pending)

Saved $200 bucks and it takes up less space in the shop!

Saved $200 bucks and it takes up less space in the shop!