HighCaliberJordan

Registered

Hey guys!

So I finally have finished my build. We strapped it to the Dyno and it was just an absolute dog.

Here is the build

Gen 2 engine from a 2008 BK 5k miles

Holley HP Ecu

Aeromotive A1000 fuel system with 1:1 fpr

E-85 fuel

MPS fuel rail

82lb injectors

JE 8.7:1 Forged pistons

Base spacer

Comp CTCTR5858 Air Cooled Turbo. T3 .63 housing with polished Compressor Housing (E-Cover)

Tial blow off valve and wastegate

3” straight pipe exhaust

Upgraded ape valve springs

I took the head in to have it milled and 5 angle valve seats.

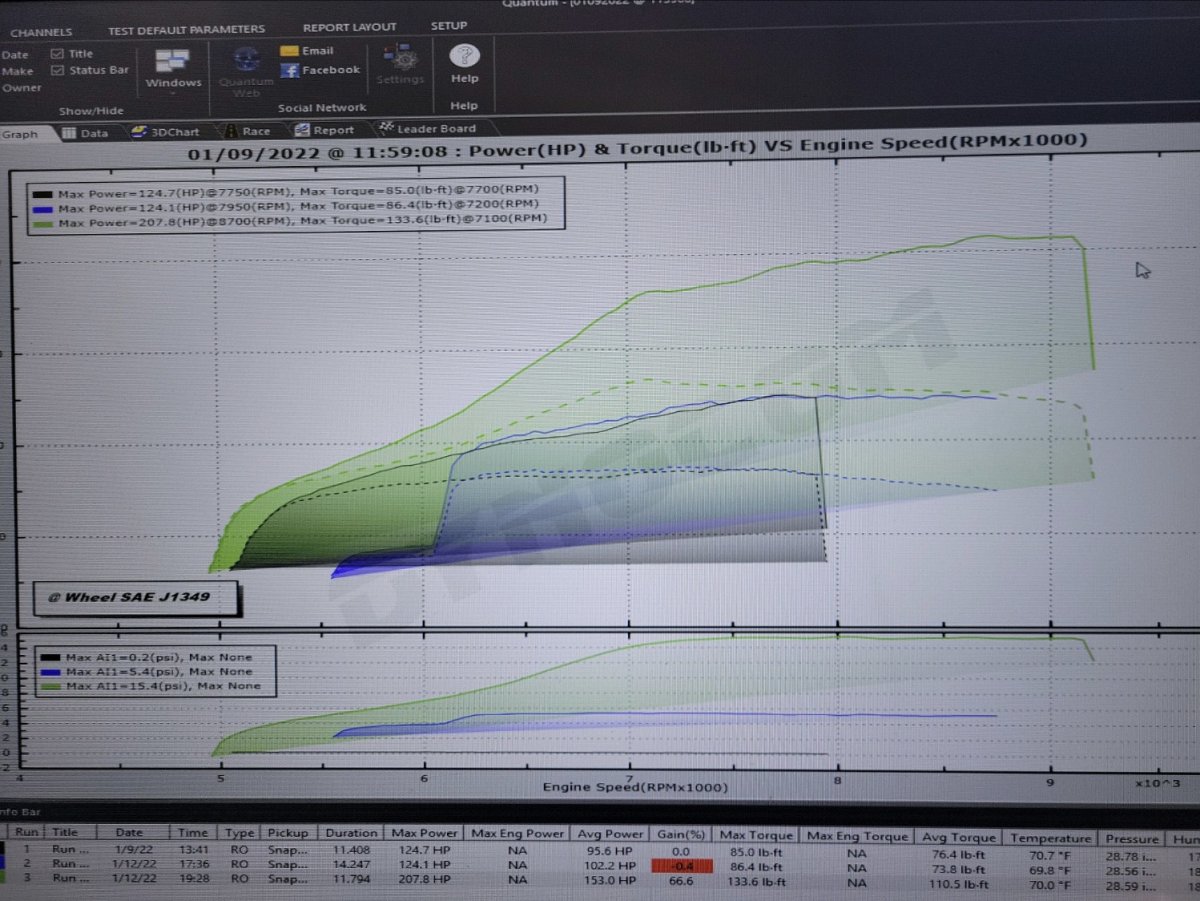

We did a few pulls and at 4psi, it was making 125hp.

We have turned it up to 15psi and are getting 207hp. Something does not seem right at all here. Does anyone have any ideas? Do you think I put the camshaft chain on off a bit? Is there any adjustment to the timing to accommodate for the base spacer?

Any idea of where to start looking would be greatly appreciated.

So I finally have finished my build. We strapped it to the Dyno and it was just an absolute dog.

Here is the build

Gen 2 engine from a 2008 BK 5k miles

Holley HP Ecu

Aeromotive A1000 fuel system with 1:1 fpr

E-85 fuel

MPS fuel rail

82lb injectors

JE 8.7:1 Forged pistons

Base spacer

Comp CTCTR5858 Air Cooled Turbo. T3 .63 housing with polished Compressor Housing (E-Cover)

Tial blow off valve and wastegate

3” straight pipe exhaust

Upgraded ape valve springs

I took the head in to have it milled and 5 angle valve seats.

We did a few pulls and at 4psi, it was making 125hp.

We have turned it up to 15psi and are getting 207hp. Something does not seem right at all here. Does anyone have any ideas? Do you think I put the camshaft chain on off a bit? Is there any adjustment to the timing to accommodate for the base spacer?

Any idea of where to start looking would be greatly appreciated.