Kiwi Rider

Registered

Have a look at this and give me your thoughts on how this could possible eventuate and end up like this…

Bike is a Suzuki VZ1500 Boulevard 2009 model, 30,000 miles on the clock and appears to have never had any major repairs, only servicing.

Owner brought it into work with a horrible whirring/whining noise on decel in all gears, slight noise on power but really bad on decel.

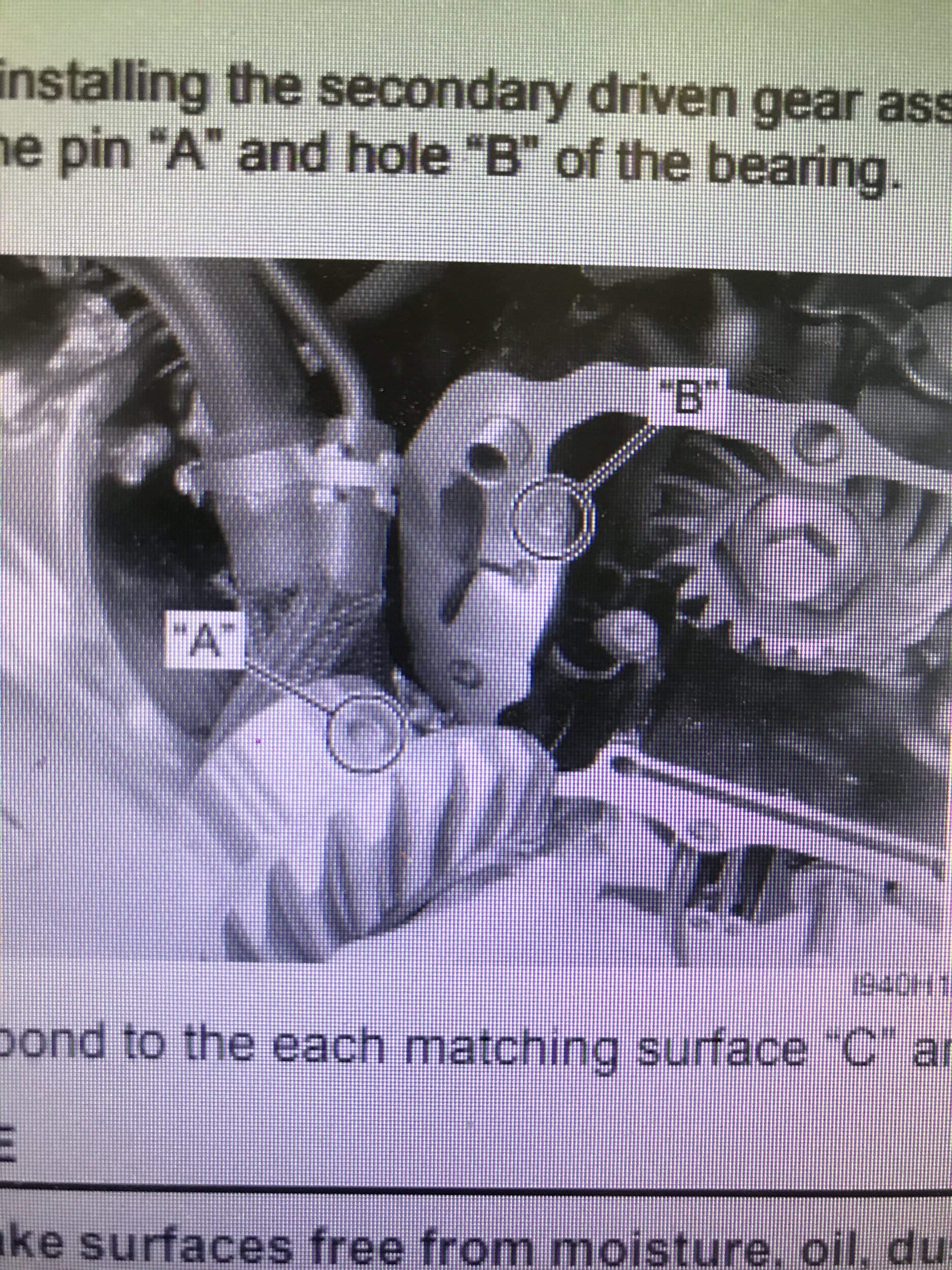

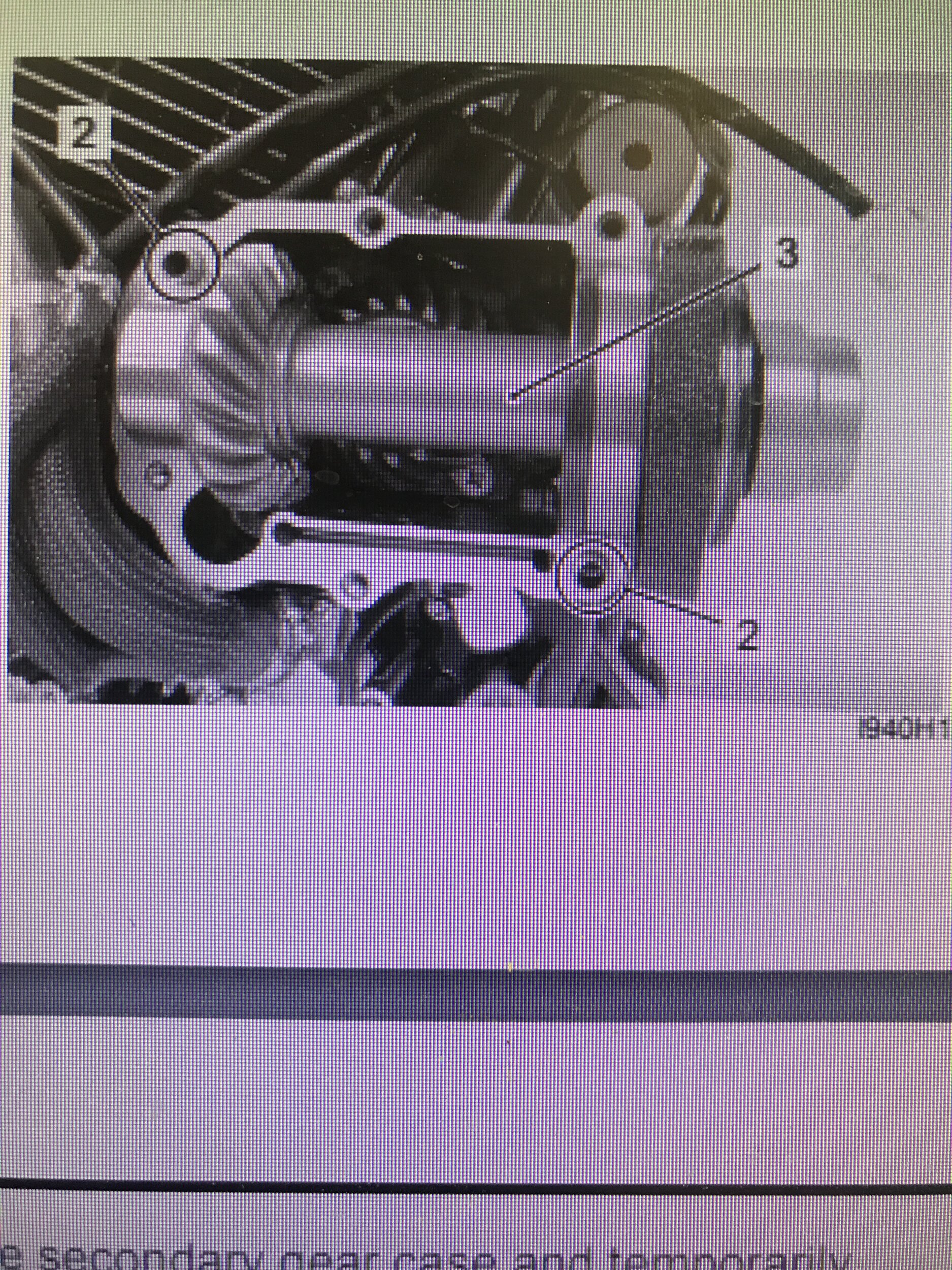

After narrowing down the area the noise was coming from it appeared to be from the output shaft area.

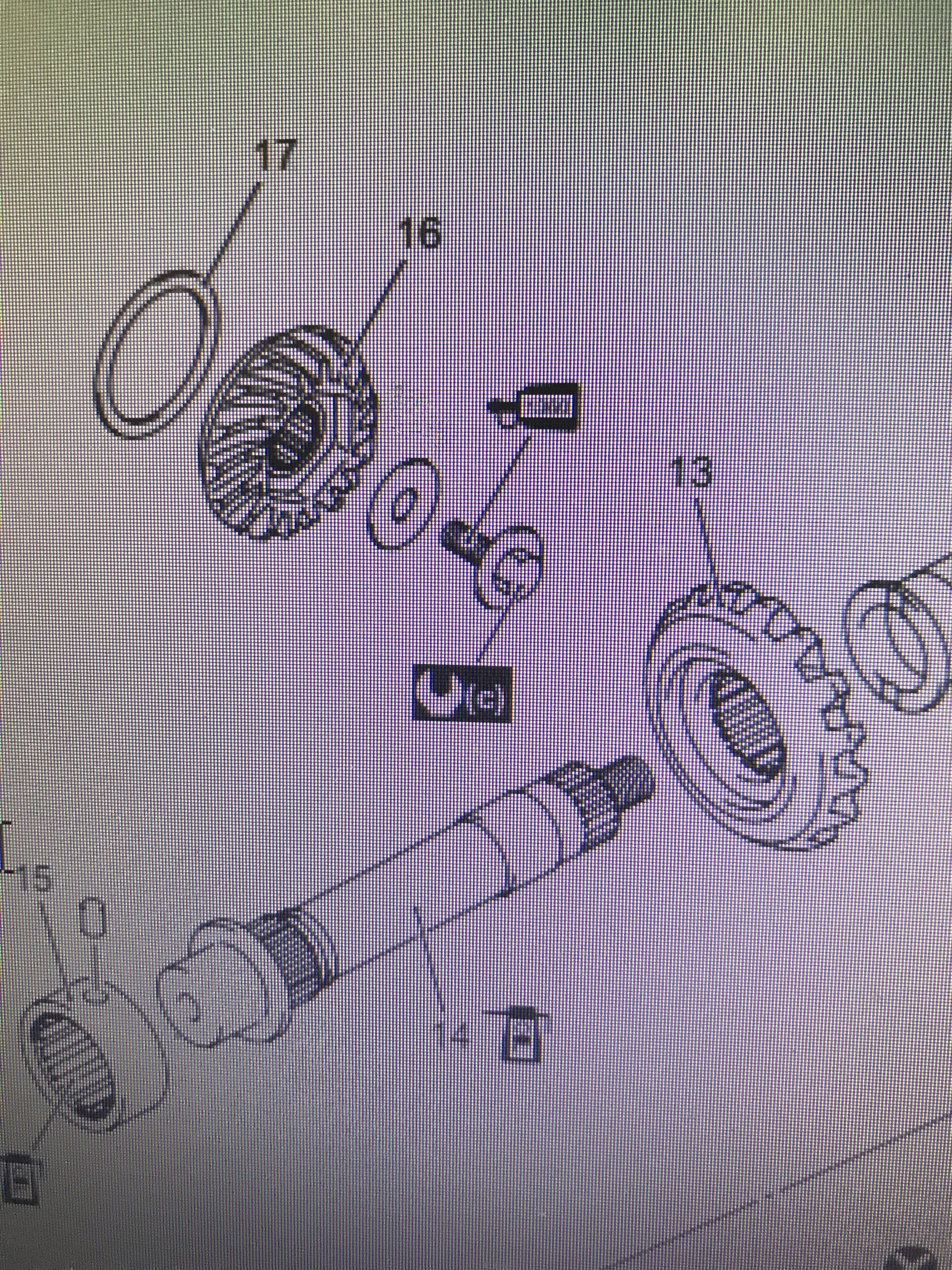

The bevel drive gear coming from the output shaft of the gearbox is retained by a large No. 10 graded bolt and shim type washer. The head of the bolt and the washer had snapped clean off the threaded end of the bolt, and dropped down into the housing narrowly avoiding being crunched by the bevel drive.

Here’s some pics… crazy huh?

We have theorised about the cause of the break in the bolt, but I’m really interested to hear what y’all think…

Bike is a Suzuki VZ1500 Boulevard 2009 model, 30,000 miles on the clock and appears to have never had any major repairs, only servicing.

Owner brought it into work with a horrible whirring/whining noise on decel in all gears, slight noise on power but really bad on decel.

After narrowing down the area the noise was coming from it appeared to be from the output shaft area.

The bevel drive gear coming from the output shaft of the gearbox is retained by a large No. 10 graded bolt and shim type washer. The head of the bolt and the washer had snapped clean off the threaded end of the bolt, and dropped down into the housing narrowly avoiding being crunched by the bevel drive.

Here’s some pics… crazy huh?

We have theorised about the cause of the break in the bolt, but I’m really interested to hear what y’all think…