So here's another result I had from the last Maxton event I thought I would share with everyone. It seems I may have to look for a new fuel pump. I've been running the same pump for many years now. This might be a good time to try a bosch 044 to see how well it runs in my fuel system.

The first graph is a graph I always plot for fuel pressure and oil just to see at a glance if there are any major issues going on with fluid pickup. If during accelaration there's a drop in either it could indicate that the pickup is not completely submerged/covered.

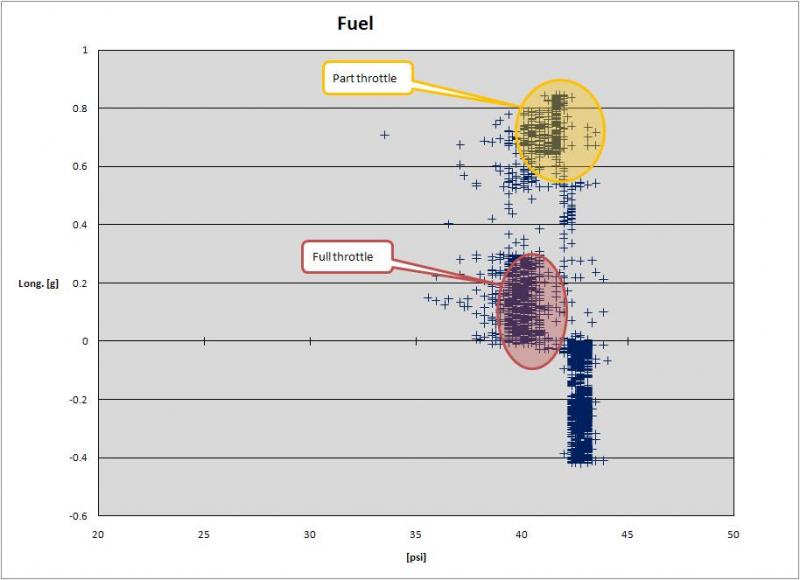

In the second graph I look at the pressure and include the throttle position. This tells me how hard the fuel system is working. You can see that once I go to full throttle there's a drop in pressure.

I also check fuel pressure vs voltage to see if a drop in pressure may be caused by a drop in voltage to the pumps. That one checks out fine with the new electrical system.

Before things get worse with this pump I'll swap in a different one to see if this goes away.

The first graph is a graph I always plot for fuel pressure and oil just to see at a glance if there are any major issues going on with fluid pickup. If during accelaration there's a drop in either it could indicate that the pickup is not completely submerged/covered.

In the second graph I look at the pressure and include the throttle position. This tells me how hard the fuel system is working. You can see that once I go to full throttle there's a drop in pressure.

I also check fuel pressure vs voltage to see if a drop in pressure may be caused by a drop in voltage to the pumps. That one checks out fine with the new electrical system.

Before things get worse with this pump I'll swap in a different one to see if this goes away.

I agree the 2psi drop isn't a big deal. If it were a bigger drop I would have some concerns. I just gets nuts sometimes trying to eliminate variables. I'm a bit curious to see if swapping the single return line to the tank with a -8 to see if it has any effect. I've got plenty of line and fittings so there isn't any costs involved. Swapping pumps would allow me to compare one against the other.

I agree the 2psi drop isn't a big deal. If it were a bigger drop I would have some concerns. I just gets nuts sometimes trying to eliminate variables. I'm a bit curious to see if swapping the single return line to the tank with a -8 to see if it has any effect. I've got plenty of line and fittings so there isn't any costs involved. Swapping pumps would allow me to compare one against the other.  to the vavle..

to the vavle..