FireMedic

Registered

Gen 1

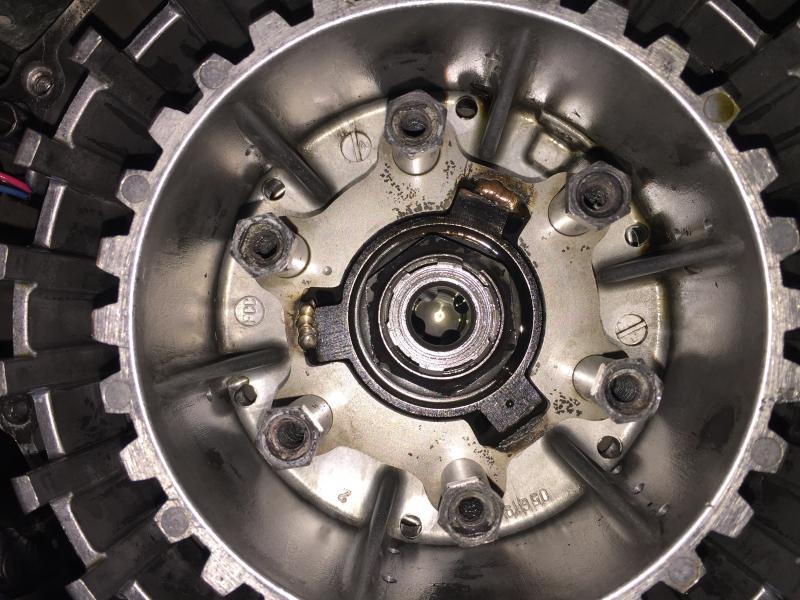

Had some motor work done by a reputable builder and welding up clutch was part of the deal. Stock clutch, 4 HD clutch springs with OEM Stack. I've been fighting clutch issues since bike got on dyno. The tuner went for the first nitrous pull and after pull shut down the bike telling me I need HD springs. Put 4 HD springs in and clutch has been good for a few rides.

About a week ago after riding about an hour I bike felt like it lost power and clutch started slipping worse then ever in all gears. I babied the bike home and talked the guy who tuned the bike. I was told to try and throw an extra steel plate in the middle of stack (2.06 stack height/it was at 1.98".)

I figured the "weld piece" would be in oil pan but it is not. I removed clutch cover and oil pan with out seeing any metal piece. I/m not sure when it this happened. Looking for some advice on what to do next or what might be going on.

Any help appreciated

Had some motor work done by a reputable builder and welding up clutch was part of the deal. Stock clutch, 4 HD clutch springs with OEM Stack. I've been fighting clutch issues since bike got on dyno. The tuner went for the first nitrous pull and after pull shut down the bike telling me I need HD springs. Put 4 HD springs in and clutch has been good for a few rides.

About a week ago after riding about an hour I bike felt like it lost power and clutch started slipping worse then ever in all gears. I babied the bike home and talked the guy who tuned the bike. I was told to try and throw an extra steel plate in the middle of stack (2.06 stack height/it was at 1.98".)

I figured the "weld piece" would be in oil pan but it is not. I removed clutch cover and oil pan with out seeing any metal piece. I/m not sure when it this happened. Looking for some advice on what to do next or what might be going on.

Any help appreciated

..

..