Yes I tried to keep the system as simple and neat as possible but on saying that I have still had to resort to an external reg and return line. I maybe would have been as well to do it your way. It is nice not to have to find space for a big pump though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Supercharged BKing

- Thread starter vampire

- Start date

More options

Meta tagsvampire

Registered

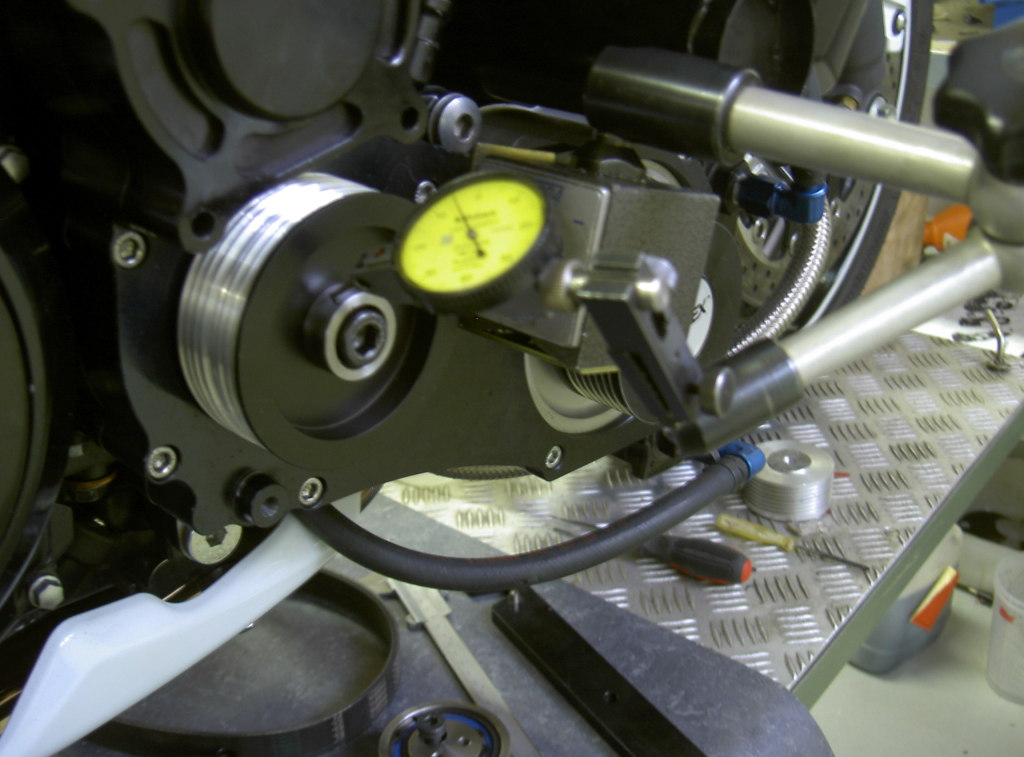

The new 78 mm cranck pulley is on. Important to set the bearing cup in the central position. I think this is the minimum possible size without modification to the outer cover plate. When you go smaller you at least have to grid some aluminum away on the inside of the coverplate were the bolds for the TTS cover come through. At the charger side 82 mm is the maximum size without mod., go bigger and the belt will touch the outer plate.

B-12

Registered

If you pull so much ignition out ,does not the ECU switch to "secure mode" (sorry for my leak of terms)

Readed somewere that the ECU will only accept xx degres and then go automaticaly to secure mode in combination with the "not fitting" signals of crank-and camshafts.

I mean the sensors go out of acceptabel range for the ECU.

But i have a GENI Busa !

greets

Bernie

Readed somewere that the ECU will only accept xx degres and then go automaticaly to secure mode in combination with the "not fitting" signals of crank-and camshafts.

I mean the sensors go out of acceptabel range for the ECU.

But i have a GENI Busa !

greets

Bernie

B-12

Registered

Thanks Kees

How much boost did you make with the 40mm restrictor ?

Have 80+80 pulleys but some issues mounting the belt. 78 on crankshaft seems to be perfect. The Gen1 should be a bit lower in rpms than yours with the GEN2 maps.

Have mounted a 05thu cometic spacer ,bigger intank fuelpump with 180l flow (AudiV8) and tested S2000 injectors with a range from real 340ccm to 348ccm.

Think this will do it with ignition pull.

greets

How much boost did you make with the 40mm restrictor ?

Have 80+80 pulleys but some issues mounting the belt. 78 on crankshaft seems to be perfect. The Gen1 should be a bit lower in rpms than yours with the GEN2 maps.

Have mounted a 05thu cometic spacer ,bigger intank fuelpump with 180l flow (AudiV8) and tested S2000 injectors with a range from real 340ccm to 348ccm.

Think this will do it with ignition pull.

greets

vampire

Registered

In had it on the dyno, mapping till 50% TPS. Boost around 16psi on the gauge at 9000 rpm. I forgot to make a datalog to get the exact boost figures, but will do next time. Pulley size at that moment was 85 crank, 80 on charger. As soon as possible we'll fifnish dyno with the new pulley ratio. I never had a cone in it. had made one, but don't like the idea of restricting this way. What 's your issue with the belt? 80/80 seems to me to fit well. The belt i used on the 85/80 also fits at 78/80. Tensioner is positioned a bit lower but no problems .

B-12

Registered

In had it on the dyno, mapping till 50% TPS. Boost around 16psi on the gauge at 9000 rpm. I forgot to make a datalog to get the exact boost figures, but will do next time. Pulley size at that moment was 85 crank, 80 on charger. As soon as possible we'll fifnish dyno with the new pulley ratio. I never had a cone in it. had made one, but don't like the idea of restricting this way. What 's your issue with the belt? 80/80 seems to me to fit well. The belt i used on the 85/80 also fits at 78/80. Tensioner is positioned a bit lower but no problems .

Belt is to short , i cant mount the tensioner (need just 2mm to hit the tread of the tensioner correctly) must look for the number or lenght of it.

Do you plan an intercooler ?

I have a brand new MC-express turbo cooler ,but to match it all tubings have to be changed. So i decided to mount it as the kit comes from Richard to get it running.

Daily job is killing me ,and i have to spend a bit time with my family so the Charged Busa is a real sleeper.......a garage sleeper ??????

vampire

Registered

Lenght is on the belt. I got a Contitech 7 PK 648. 7 is the number of ribs, PK the type and 648 the lenght in MM. For the smaller pulley i also got a GoodYear Poly-V 630. So 630mm, 18 mm shorter. I keep it as a spare part, the Conti still fits. When you got the same Coti belt, it will fit. I had it on the 85/80 pulley without a problem. On the 78 it's a bit close to the charger pulley, but still okay. Did you first put the belt on the both pulleys and then mount the tensioner?

B-12

Registered

Hi

sorry for late reply

i have also the 648 belt. 80mm is messured the outer diameter of pulleys.

Yes ,i put first the belt on the pulleys ,and then tried to mout the tensioner. By hand i could not push it so far "down" to catch the thread for the tensioner bolt. Any trick ?

If i stick a hexwrench throuh the tensioner i can move it a bit downwards and it would fit. But no way to push it by hand or with my tumb And i think it should fit in this position easy as its not "tensioned"

And i think it should fit in this position easy as its not "tensioned"

Maybe i do it just the wrong way ?

Thanks for support

sorry for late reply

i have also the 648 belt. 80mm is messured the outer diameter of pulleys.

Yes ,i put first the belt on the pulleys ,and then tried to mout the tensioner. By hand i could not push it so far "down" to catch the thread for the tensioner bolt. Any trick ?

If i stick a hexwrench throuh the tensioner i can move it a bit downwards and it would fit. But no way to push it by hand or with my tumb

And i think it should fit in this position easy as its not "tensioned"

And i think it should fit in this position easy as its not "tensioned" Maybe i do it just the wrong way ?

Thanks for support

vampire

Registered

If your bracket for the chrager has the same dimension as a Gen2, it should easy fit. The 648 belt could do 85/80 pulley, so 80/80 on the same brackets is no problem, even a little shorter belt would fit. I put the belt on both pulleys, chargepulley has one rib more so be sure to get it in the right one( i think the outer one), then put the tensioner on and turn the excenter in top position so that you can get the bolt in . Don't think you can get wrong with it.

vampire

Registered

Today we did a first 100% TPS dyno. At the end of the day with AFR 11.5 and ignition pulled back 9 degrees it made a save 251rwhp@10100RPM and 182NM@7850Rpm. Straight line on the dyno, so when we lean it out a bit and some more revs it will easy do around 260 rwhp on this pulley ratio(78/80). Boost around 12 psi. First thing to do now is drive it for some miles to see what's it all about.

vampire

Registered

This week i finally found the time to put the BKing on the dyno for the first 100%TPS runs. At the end of the day it made 251 HP@10100Rpm at the wheel on the Dynostar. Max torque 182NM@ 7850 rpm. Ignition is pulled back 9 degr. and AFR 11.2. Boostlevel with pulley 78/80 at that point around 12 Psi on the gauge. Nice straigth dyno graphic. It needs some finetuning, but it's a good startingpoint i think.

B-king Rotrex C30-94 - YouTube[/url]

Last edited by a moderator:

vampire

Registered

Nice news

Do you limit the revs with ECU editor or just close throttle for the dyno.

Do you use the stock injectors

Rev limiter hardcut set at 11300rpm. We didn't want to hit the limiter, so gone off throtttle .Just see what AFR would do and the numbers. Using stock inj. all 8 set full open from iddle to max. revs, secundairy throttle plates same story in all gears and stock fuel pressure with a Wallbro pump.

Have you dropped the compression? What fuel are you running? What does a Bking make stock on a Dynostar? If you can get E85 then run 20% with 98oct or the best you can get. It will make a big difference, you can run 12:1 afr and maybe only 6 deg retard, it will make 50 + bhp difference. Some things to try if you are running short of fuel. The steel fuel pipe out of the tank you will notice is rolled over and reduced diameter, open it up to the full pipe dia with a dremmel its worth a lot in fuel flow. Same on the fuel rail. If you still can't get enough fuel fit a pop rivet head into the end of the fuel pressure regulator in the tank and it will run the pump at max pressure, put a T piece into the fuel line go through an adjustable regulator back to a return pipe you need to fit/weld into the tank. this will give you all the fuel and pressure you need.

vampire

Registered

Richard, i put Wossner 9:1 pistons in. Stock it made 168Hp on the dyno. Till this point no problems with fueling. I live near Germany were i can get 98 octane. Here in Holland it's hard to find.

I started with pulling back ignition 12 degrees at full trottle , but had to keep an eye on temperature rising. At that point AFR was around 10.5. So leaned out a little and set ignition to 9 degr. Shows a lot more power. As said before , it's a starting point. I got the new datalogger/ecueditor and first make some miles datalogging . TPS fueling is easy, IAP vacuum( so till about 10% TPS) is harder to get spot on. I think it has to do with the Bypass/dumpvalve. Switching from a little vacuum (valve still bleeds off a little) to a little less TPS and up again give some struggle. Not much, but try to find out on the logfiles to get it smoother.

Thanks for your advice.

I started with pulling back ignition 12 degrees at full trottle , but had to keep an eye on temperature rising. At that point AFR was around 10.5. So leaned out a little and set ignition to 9 degr. Shows a lot more power. As said before , it's a starting point. I got the new datalogger/ecueditor and first make some miles datalogging . TPS fueling is easy, IAP vacuum( so till about 10% TPS) is harder to get spot on. I think it has to do with the Bypass/dumpvalve. Switching from a little vacuum (valve still bleeds off a little) to a little less TPS and up again give some struggle. Not much, but try to find out on the logfiles to get it smoother.

Thanks for your advice.

I would think you would need very little retard with 9:1 I would run to about 24-26 deg adv.

vampire

Registered

Next time on the dyno i'll try some more ignition adv. For now i've done a lot off datalogging / autotune with the new EcE databox. But on vacuum still a problem with the bike stutter on steady throttle position . When the Blow off is just a little open it seems not consistantly bleeding off air. I've tried to set the spring +, but it didn't help. As soon as i change throttle position it's okay, then keeping it there with just a little vacuum, stutter comes in again. Any idea?

vampire

Registered

Hi Paul, ISC is hooked on the plenum with a banjo fitting and still activ on the EcE. But it's a thing to look after. On idle in neutral after a while rpm is just falling down to 800rpm and AFR gauge shows values around 18.0. So there's something to look after anyway. I got the same problem with the blow off. After two days or longer it's stuck. After a couple of miles it suddenly opens. I think the stuttering is caused by the valve not working like it should, but maybe i'm forgetting/ not seeing something.

Similar threads

- Replies

- 30

- Views

- 3,049