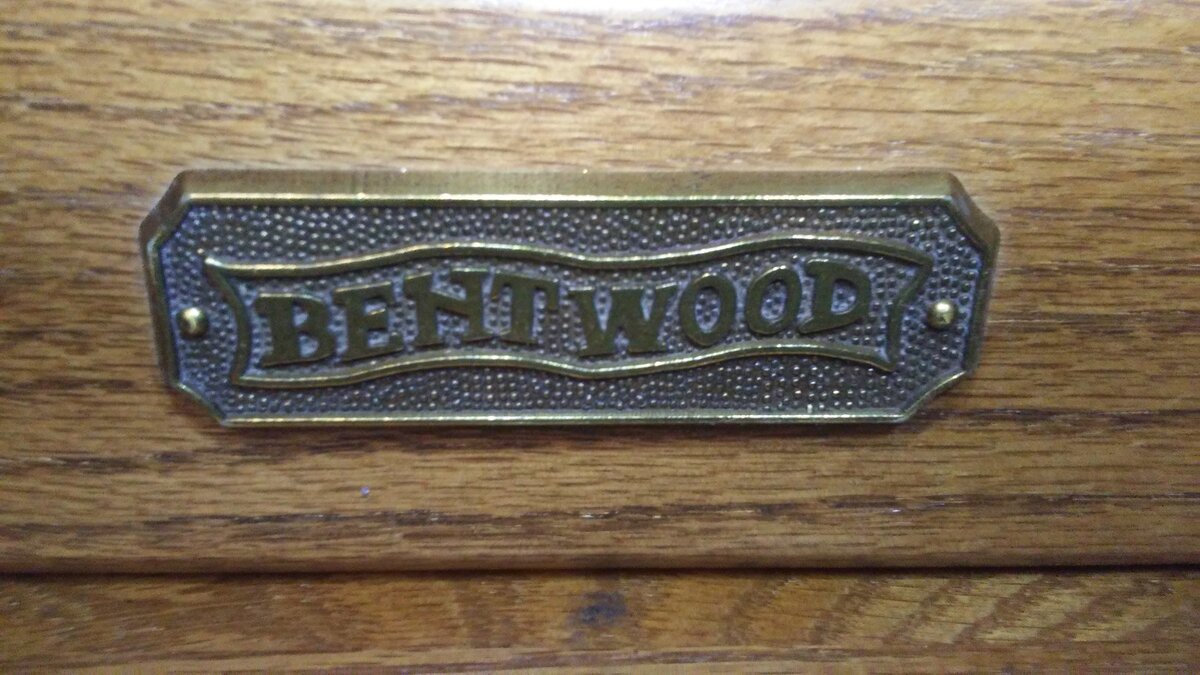

My "Anti-Roomate/and her friends" safe keeping vault has broken. Not much company info except perhaps a company in Oregon,USA.

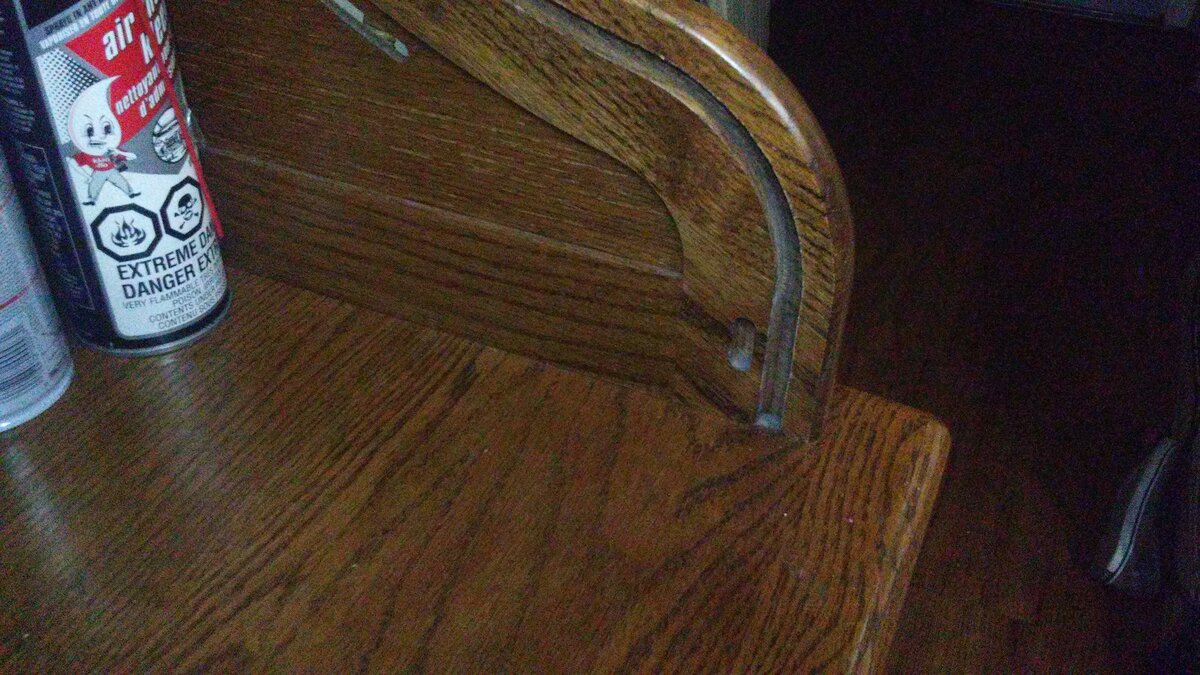

I'm guessing thats where it was manufactured. One site says "Closed" permanently. Anyways, was wondering if anybody knew what the material was that is used on the inside to give the wood that flexibility to open/close as it rolls up/down. My idea is to use some type of cloth,scuff up the surface and glue on a full length patch using contact cement.It almost looks like some type of heavy paper or something. The 2 halves have separated as clean as if it was cut with a razor blade or scalpel,it's that clean of a break.

Idea's? I would prefer to avoid total disassembly of the desk upper,even thou it appears not to have been glued during manufacture.

IDK....feels more like paper than cloth...

It may come apart nicely...you can see daylight between the contact joints.

But what an' undertaking...

Thanks,

Rubb.

I'm guessing thats where it was manufactured. One site says "Closed" permanently. Anyways, was wondering if anybody knew what the material was that is used on the inside to give the wood that flexibility to open/close as it rolls up/down. My idea is to use some type of cloth,scuff up the surface and glue on a full length patch using contact cement.It almost looks like some type of heavy paper or something. The 2 halves have separated as clean as if it was cut with a razor blade or scalpel,it's that clean of a break.

Idea's? I would prefer to avoid total disassembly of the desk upper,even thou it appears not to have been glued during manufacture.

IDK....feels more like paper than cloth...

It may come apart nicely...you can see daylight between the contact joints.

But what an' undertaking...

Thanks,

Rubb.