You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More extreme weight reduction

- Thread starter Draco1340

- Start date

More options

Meta tags

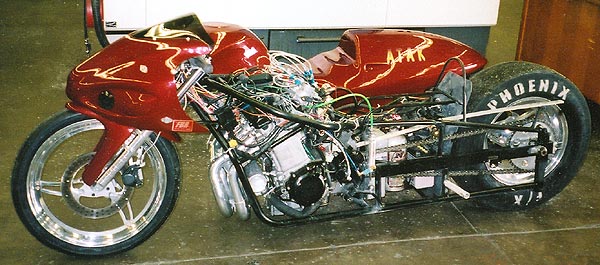

one of these weighs about 380

But it is not street legal!

Draco1340

Registered

OK, so this is the finished product. 452 lbs all gassed up. 129 mph in the 1/8th and 159 in the 1/4 on Motor only for a 100% street legal insured inspected Hayabusa. I got a couple of 30# Spray passes in at 165 mph before the clutch welded itself together into a molten mass of stench.

Note the antiskid tape on seat. That was after I went off the back on first pass.

Note the antiskid tape on seat. That was after I went off the back on first pass.

Looks good Tom.  To keep from slipping on my seat I always put a strip of leather on it. Leather seat to leather butt gave no slip.

To keep from slipping on my seat I always put a strip of leather on it. Leather seat to leather butt gave no slip.

How did things work out with your battery?

To keep from slipping on my seat I always put a strip of leather on it. Leather seat to leather butt gave no slip.

To keep from slipping on my seat I always put a strip of leather on it. Leather seat to leather butt gave no slip. How did things work out with your battery?

Draco1340

Registered

I left the stock battery in the bike this past weekend because I was flashing the ECU every pass. I finally dumped my Power Commander, and needed to convert my motor map and my nitrous map over to ECU editor. The flashes can take up to 4 minutes, and the logger is also a power hog, so to be safe I left my "Dewalt Special" in the trailer. I will test the A123 battery and a new clutch cooler next weekend running Top Bike. I plan on checking the balance of each cell for the first couple of weeks, but from what I can tell, this new battery doesn't un-balance itseft very quickly.

The long flash time is why I still have a PC on my bike. I make multi correction in there and then at the end move it over to the ECU and zero it out again. It just saves alot of time.

What are your plans for clutch cooling? Did you just have to much slip in the clutch?

What are your plans for clutch cooling? Did you just have to much slip in the clutch?

Draco1340

Registered

If you leave ECU editor open, the updates are only 30 seconds each. Its only when you open it for the first time that it takes ~ 4 minutes. I'm still learning the little tricks

Clutch cooling... I used to measure the clutch cover and wait for the temp to drop below 130F before taking a pass. But depending on the air temperature, there can be a big difference between plate temp and cover temp. I welded a second bung onto my cover so that I can force cool air through the clutch between passes. I have a small IR temp gauge that screws into the second bung to verify plate temps are between 120 and 170 F and I'm good to go. At some temperature, the plates warp, stick to the hub, and your all done. In theory it should work...

Clutch cooling... I used to measure the clutch cover and wait for the temp to drop below 130F before taking a pass. But depending on the air temperature, there can be a big difference between plate temp and cover temp. I welded a second bung onto my cover so that I can force cool air through the clutch between passes. I have a small IR temp gauge that screws into the second bung to verify plate temps are between 120 and 170 F and I'm good to go. At some temperature, the plates warp, stick to the hub, and your all done. In theory it should work...

yup been there with the clutch welding  Sounds like a good plan to pump cool air directly at the clutch assembly.

Sounds like a good plan to pump cool air directly at the clutch assembly.

Sounds like a good plan to pump cool air directly at the clutch assembly.

Sounds like a good plan to pump cool air directly at the clutch assembly.

Draco1340

Registered

Stainless valves, 60# spring pressure, unshrouded valves, and a bit of headwork by me. Nothing else. I have a set of .350 / .370 cams to go in later next month, but I wanted to see what weight reduction would do for me first. I should be able to creep up on a 70 N2O shot by mid summer.

badass1000

Registered

I am trying to do what I can within reason and keep it reliable, and looking stock. It is my street bike.

I removed one of the fans with no issues. removed the gaurds off of the one I left on.

My DME stock replacement subframe showed up fri. Great looking piece. Only complaint is no hooks for the helmet. This is nice when I go somewhere and leave my helmet outside locked to the bike. Also some times on ocasion I will ride down town with no helmet and glasses on, but have my helmet straped to the side for when I go ride after going down town. Took it to the local fab shop I use and had a hook fabed up and welded on this mourning.

Bare stock subframe was 9lbs 10.5oz.

DME stock replacement subframe was 3lbs 6.25oz.

going to get a small 8 cell 1.7lb lithium battery put in the next couple days. Then going to measure the fully adjustable lowering links I have now and have a piece of aluminium bar stock cut and drilled to replace the fully adjustable ones. fully adjustable ones were a couple pounds.

Really want to remove the passenger pegs and brackets, but leave them on for the females once in awhile.

I really should of had the passenger peg brackets machined down some before I had them powdercoated. passenger peg brackets and aluminium passenger pegs is still almost 3lbs if I remember correctly.

I removed one of the fans with no issues. removed the gaurds off of the one I left on.

My DME stock replacement subframe showed up fri. Great looking piece. Only complaint is no hooks for the helmet. This is nice when I go somewhere and leave my helmet outside locked to the bike. Also some times on ocasion I will ride down town with no helmet and glasses on, but have my helmet straped to the side for when I go ride after going down town. Took it to the local fab shop I use and had a hook fabed up and welded on this mourning.

Bare stock subframe was 9lbs 10.5oz.

DME stock replacement subframe was 3lbs 6.25oz.

going to get a small 8 cell 1.7lb lithium battery put in the next couple days. Then going to measure the fully adjustable lowering links I have now and have a piece of aluminium bar stock cut and drilled to replace the fully adjustable ones. fully adjustable ones were a couple pounds.

Really want to remove the passenger pegs and brackets, but leave them on for the females once in awhile.

I really should of had the passenger peg brackets machined down some before I had them powdercoated. passenger peg brackets and aluminium passenger pegs is still almost 3lbs if I remember correctly.

Last edited:

Similar threads

- Replies

- 6

- Views

- 1,294