You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good deeds: DIY slave cover support

- Thread starter tnarmyng

- Start date

More options

Meta tagsMythos

Registered

Nice. I have the one from Exoticycle. I'm sure extra reliable being that it goes across the top of the slave cylinder but it's heavy. That should be improved by replacing the steel bolts with aluminum but the aluminum brace itself is quite a chunk of metal. Take a picture of yours on a scale if you want. I can weigh mine for comparison.

michael parris heuberger

Registered

Hi. This is a good way to protect the output shaft and the cases, go with the Robinsons output shaft support kit.Nice. I have the one from Exoticycle. I'm sure extra reliable being that it goes across the top of the slave cylinder but it's heavy. That should be improved by replacing the steel bolts with aluminum but the aluminum brace itself is quite a chunk of metal. Take a picture of yours on a scale if you want. I can weigh mine for comparison.

Mythos

Registered

For me, that's a YES and a NO. I have a Woodcraft stator cover and it weighs a ton compared to the OEM cover. On the other hand, I recently crashed a bike and one of the OEM covers crushed and ground through on the pavement. A heavy duty billet cover will withstand a crash a lot better than an OEM cover but they're boat anchors.My ape bracket fit like garbage and I had to bend the overflow tube more than my liking I'd pay the money and go billet RCC cover for sure.

Last edited:

Mythos

Registered

I investigated that when I bought the "billet" countershaft sprocket nut from Robinson. I see how it's designed to ride inside the support bracket. If I go turbo, I will definitely go with that setup. I gotta mention though, "billet" means carved from a block of solid metal. It's usually aluminum but billet can be any metal. The Robinson countershaft sprocket nut was lighter than OEM but it was still steel. Steel is a better choice being that it could rub against the support bracket under huge torque but it's still heavy. Stronger almost always means heavier. I didn't think it was necessary for an NA busa so I went with an aluminum sprocket nut instead.Hi. This is a good way to protect the output shaft and the cases, go with the Robinsons output shaft support kit.

JeffSyh

Registered

Biggest bonus to the billet cover is it doubles as a support and case saver since a chain will never bust through it! I'll probably upgrade to the RCC this winter and just give away the ape support.For me, that's a YES and a NO. I have a Woodcraft stator cover and it weighs a ton compared to the OEM cover. On the other hand, I recently crashed a bike and one of the OEM covers crushed and ground through on the pavement. A heavy duty billet cover will withstand a crash a lot better than an OEM cover but they're boat anchors.

The biggest failure of the stock cover is that Heavier clutch springs will break the coverBiggest bonus to the billet cover is it doubles as a support and case saver since a chain will never bust through it! I'll probably upgrade to the RCC this winter and just give away the ape support.

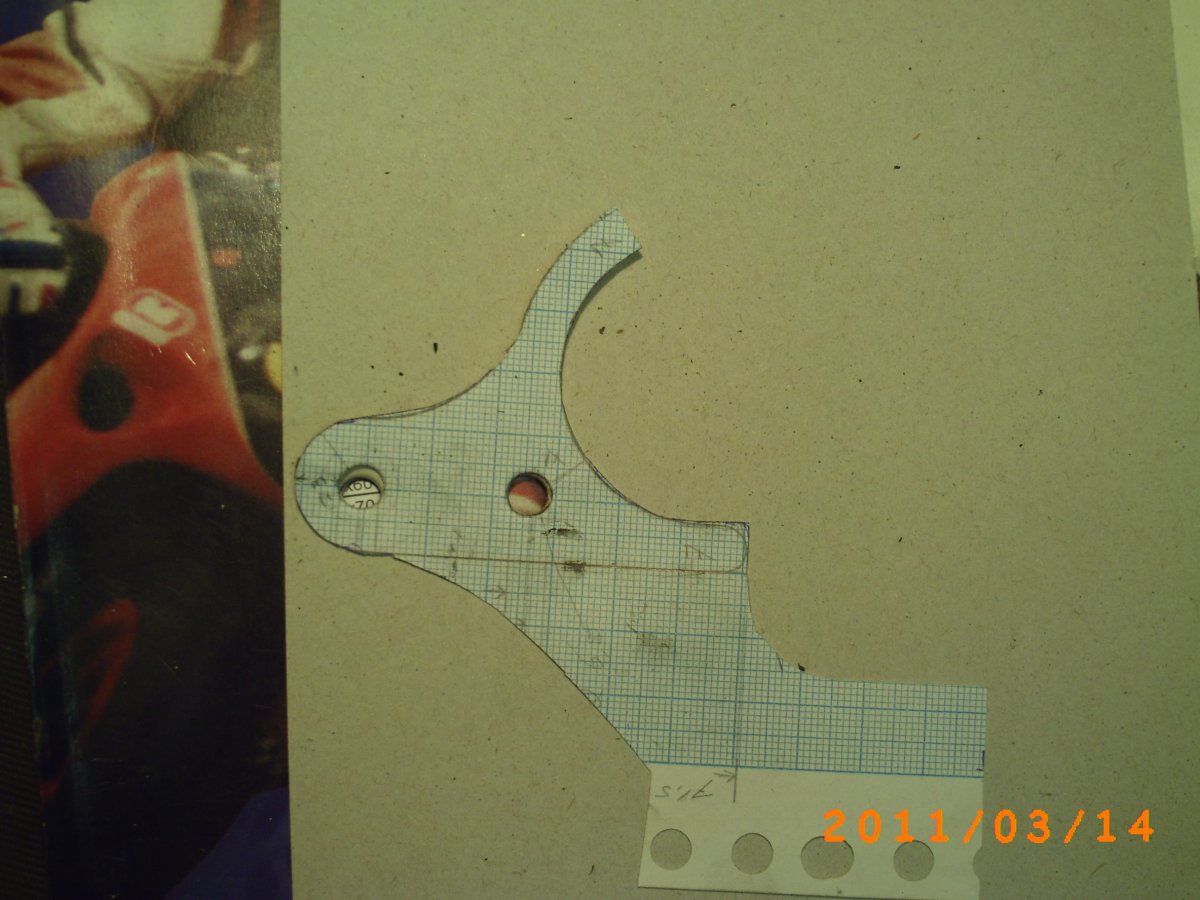

I tried 6061 T6 but made the mistake of getting a HALF INCH lol. Impossible to plasma cut an overall a kick in the nurts. Went with carbon steel (didn't exist before last week as far as I knew lol) for the current model. I've got some very minor trimming to do still but just this...Nice. I have the one from Exoticycle. I'm sure extra reliable being that it goes across the top of the slave cylinder but it's heavy. That should be improved by replacing the steel bolts with aluminum but the aluminum brace itself is quite a chunk of metal. Take a picture of yours on a scale if you want. I can weigh mine for comparison.

.. spitballing, close to 1.5 lbs and only 1/4". Good thing I'm only 145 lbs

But hey, at $13 bucks for the plate, a 16 min drive from home to grab it, and an hour or so to get it 95% on point, so far, beats the hell out of a week+ shipping and handling time, $10 shipping, and +$60, plus tax. The wait was what got me into the DIY state of mind.... mostly.

Bigboy Busa2

Registered

Michael always calling out parts that cost as much as everyone else car paymentHi. This is a good way to protect the output shaft and the cases, go with the Robinsons output shaft support kit.

VERY time consuming.. FOR ME. But had there been a good template accessible.. an hour tops. Which is why I decided to share the exact dims via CAD, simpler 3D template w/ measurements, and a cheapo bolt-to-bolt + 10 various measurements for the real DIYer.It's time consuming but I just draw up a template, cut out of aluminum stock and file it down. The APE looks like it's made from a 1/8" plate.

SOMEone will have a race in the future's near future.

^ Options: They're IMPOSSIBLE to find "used", ~5-10 day delivery time w/ weekends for new, and a solid 6 hours with creating a template, sourcing, trial-and-error grinding to proper fitment + install.

My aim is to T mine up and share it all, so the next ME can pop one out in an hour or two for that race or ride they want to make, or penny-pinching DIYer who can use the extra $60 bucks toward the other part they need.

Popie

Registered

I really think the Slave Support that goes right over the center of the cylinder is better than the one we're talking about here... Hayabusa Billet Aluminum Slave Support Block BLACK | eBay

Bigboy Busa2

Registered

Had to bend mine also. Was rubbing against hose. And the rcc is worth the insurance. I just wish it had a piece for the bottom to protect the shift shaft cover. Like it protects the water pump. Thats a new cover you see. Guess why.My ape bracket fit like garbage and I had to bend the overflow tube more than my liking I'd pay the money and go billet RCC cover for sure.

I

Much easier to source a plate than a block for a DIY, though.

Conceptually I agree, although I'd like to see the springs that could budge my carbon steel mock up.I really think the Slave Support that goes right over the center of the cylinder is better than the one we're talking about here... Hayabusa Billet Aluminum Slave Support Block BLACK | eBay

View attachment 1639708

Much easier to source a plate than a block for a DIY, though.

Bigboy Busa2

Registered

If I knew then what I do now. Yes, that's what I would get. About same price tooI really think the Slave Support that goes right over the center of the cylinder is better than the one we're talking about here... Hayabusa Billet Aluminum Slave Support Block BLACK | eBay

View attachment 1639708

Vanishing Point

Registered

My 2 finger type diy 10mm

Nice! What length bolts and spacers did you run on those? That'd get me 1/2 of the way there!

Similar threads

- Replies

- 23

- Views

- 1,486

- Replies

- 887

- Views

- 35,269

- Replies

- 9

- Views

- 5,946