Big thanks to Petrik :thumb:

This is working very nicely now with a few folks besides myself using it as well. You would have to have the gm 3 bar map sensor conversion on the bike to use this.

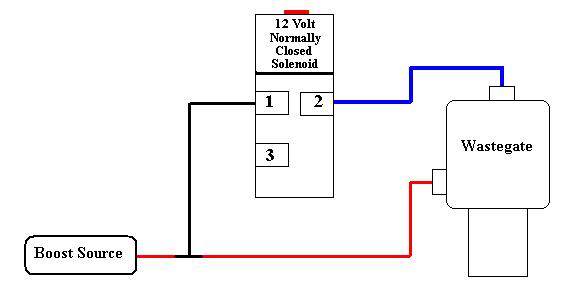

Hooking it up is very easy, just plug the solenoid into the PAIR output valve, Tee into the line going to the bottom of your wastegate, and plumb that to solenoid inlet, solenoid outlet goes to top of wastegate with as short of a run as possible. I have my solenoid secured to the harness about 4 inches from the wastegate.

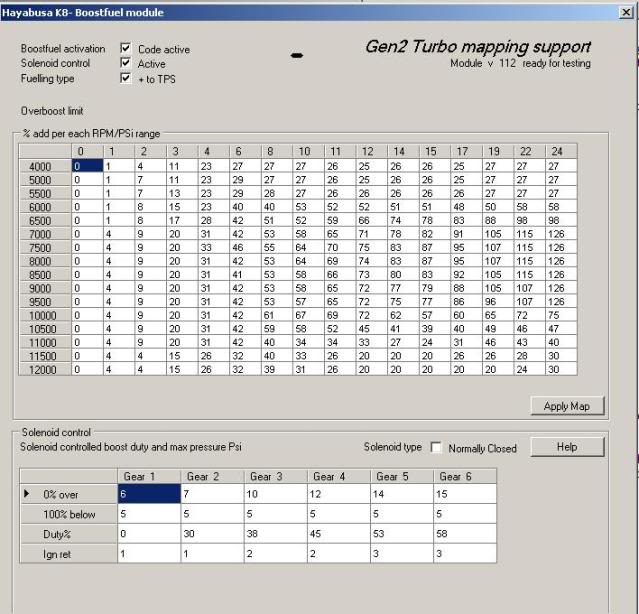

Regarding the software, there are 4 main tuning parameters

Duty%: This is how you actually set the boost level, 0% duty cycle means solenoid never turns on and you make no boost over gate spring.

100% duty cycle means you add as much air as possible to the top of wastegate which results in HUGE boost. Everything in between is

where you want to be. You will find depending on your setup it seems to take approx 30% duty cycle before any measurable amount

of boost is added. Then from there use small increments to see the effect. Keep in mind, not enough duty cycle = boost lower than you

want, too much duty results in jerky performance. It sounds complicated at first, but doesn't take long at all to setup on the bike, having

a datalogger makes it much easier than trying to watch a boost gauge. Or if on a dyno this would really be a piece of cake.

So Duty% is what controls how much open time the air solenoid has, BUT Petrik has added a couple of nice safety features as well.

0% Over: This is the max boost you want to see in each gear before you actually turn the solenoid off. Meaning if you put a value of 10 psi

here, if the map sensor sees boost pressure exceeding 10 psi, it will shut the solenoid off dropping boost back down, once below 10 psi

duty% will continue. The purpose of this feature is to prevent overboost. The real tuning should be done with the duty% value, not

this one. You could easily put 100% duty% with whatever max boost safety in there and it would limit boost to that pressure, but the

end result would be non-smooth boost traces, the bike will feel jerky. If you get your duty% set just right, where you aren't hitting

the max boost safety, then boost traces will be very smooth and bike will feel awesome.

100% Below: Basically this feature is implemented to help in spool time. The value you enter here should be right at or slightly below whatever

your wastegate produces in boost. I have a 6 psi spring, and i have 5 psi as my value here. What this does is opens up solenoid

completely until gate spring 5 psi is reached, so we are adding air to the top of the gate as much as possible to help get the bike

spooled a little quicker.

Ign Retard: This one is sort of self explanatory, but you can pull timing based on gear position with this feature.

Solenoid Plumbing

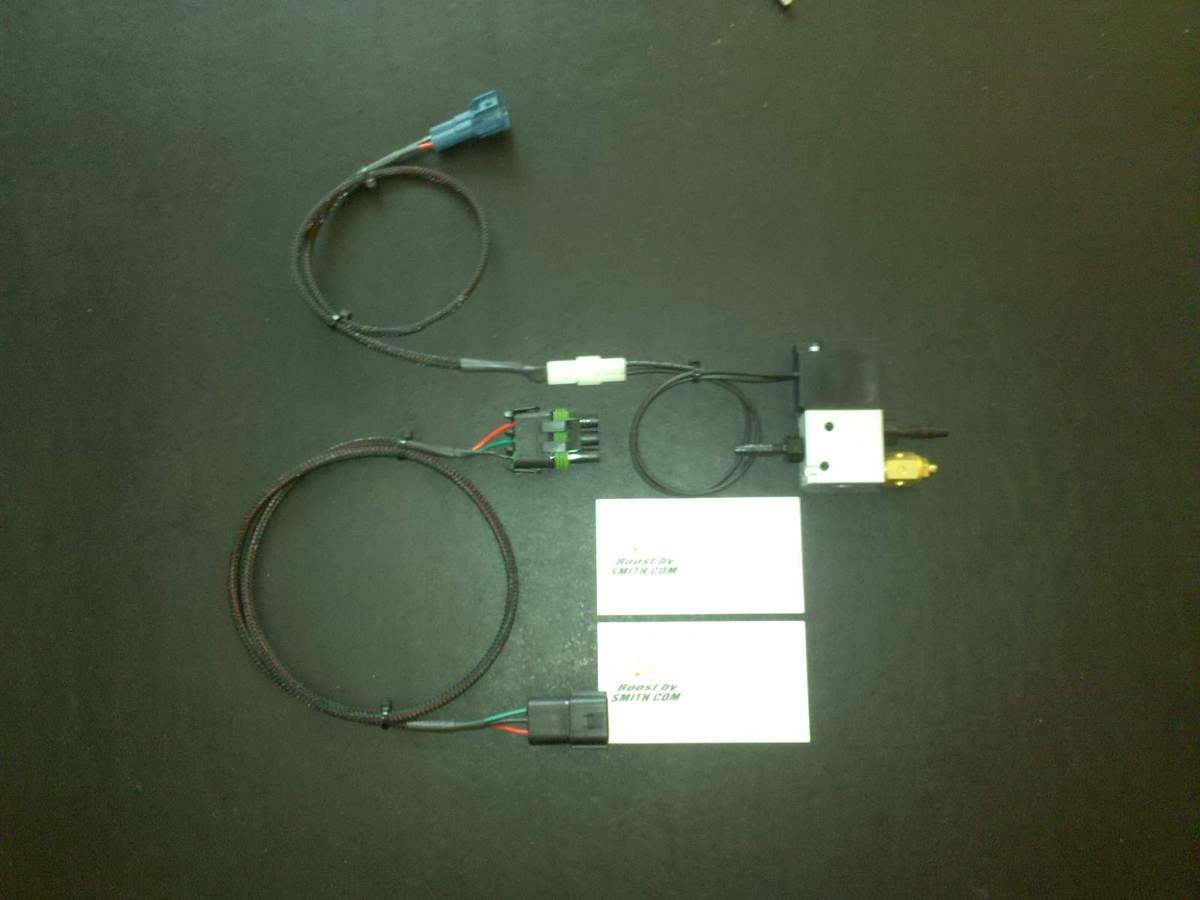

Actual kit includes

Air solenoid with brass fittings installed. Wired with voltage spike protection to PAIR valve connector

1/4" Vacuum line

1/4" Tee

3 Bar Map Sensor Adapter

(photo shows a muffler in solenoid exhaust port (not needed or included) and gm 3 bar map sensor adapter harness (not included))

This isn't the greatest datalog, not at 100% throttle much with the stock arm and road conditions, but you get the idea of increasing boost in each gear.

This is working very nicely now with a few folks besides myself using it as well. You would have to have the gm 3 bar map sensor conversion on the bike to use this.

Hooking it up is very easy, just plug the solenoid into the PAIR output valve, Tee into the line going to the bottom of your wastegate, and plumb that to solenoid inlet, solenoid outlet goes to top of wastegate with as short of a run as possible. I have my solenoid secured to the harness about 4 inches from the wastegate.

Regarding the software, there are 4 main tuning parameters

Duty%: This is how you actually set the boost level, 0% duty cycle means solenoid never turns on and you make no boost over gate spring.

100% duty cycle means you add as much air as possible to the top of wastegate which results in HUGE boost. Everything in between is

where you want to be. You will find depending on your setup it seems to take approx 30% duty cycle before any measurable amount

of boost is added. Then from there use small increments to see the effect. Keep in mind, not enough duty cycle = boost lower than you

want, too much duty results in jerky performance. It sounds complicated at first, but doesn't take long at all to setup on the bike, having

a datalogger makes it much easier than trying to watch a boost gauge. Or if on a dyno this would really be a piece of cake.

So Duty% is what controls how much open time the air solenoid has, BUT Petrik has added a couple of nice safety features as well.

0% Over: This is the max boost you want to see in each gear before you actually turn the solenoid off. Meaning if you put a value of 10 psi

here, if the map sensor sees boost pressure exceeding 10 psi, it will shut the solenoid off dropping boost back down, once below 10 psi

duty% will continue. The purpose of this feature is to prevent overboost. The real tuning should be done with the duty% value, not

this one. You could easily put 100% duty% with whatever max boost safety in there and it would limit boost to that pressure, but the

end result would be non-smooth boost traces, the bike will feel jerky. If you get your duty% set just right, where you aren't hitting

the max boost safety, then boost traces will be very smooth and bike will feel awesome.

100% Below: Basically this feature is implemented to help in spool time. The value you enter here should be right at or slightly below whatever

your wastegate produces in boost. I have a 6 psi spring, and i have 5 psi as my value here. What this does is opens up solenoid

completely until gate spring 5 psi is reached, so we are adding air to the top of the gate as much as possible to help get the bike

spooled a little quicker.

Ign Retard: This one is sort of self explanatory, but you can pull timing based on gear position with this feature.

Solenoid Plumbing

Actual kit includes

Air solenoid with brass fittings installed. Wired with voltage spike protection to PAIR valve connector

1/4" Vacuum line

1/4" Tee

3 Bar Map Sensor Adapter

(photo shows a muffler in solenoid exhaust port (not needed or included) and gm 3 bar map sensor adapter harness (not included))

This isn't the greatest datalog, not at 100% throttle much with the stock arm and road conditions, but you get the idea of increasing boost in each gear.