I have been watching this thread with great interest.

I have 2 sets of OEM wheels that I have had chromed.

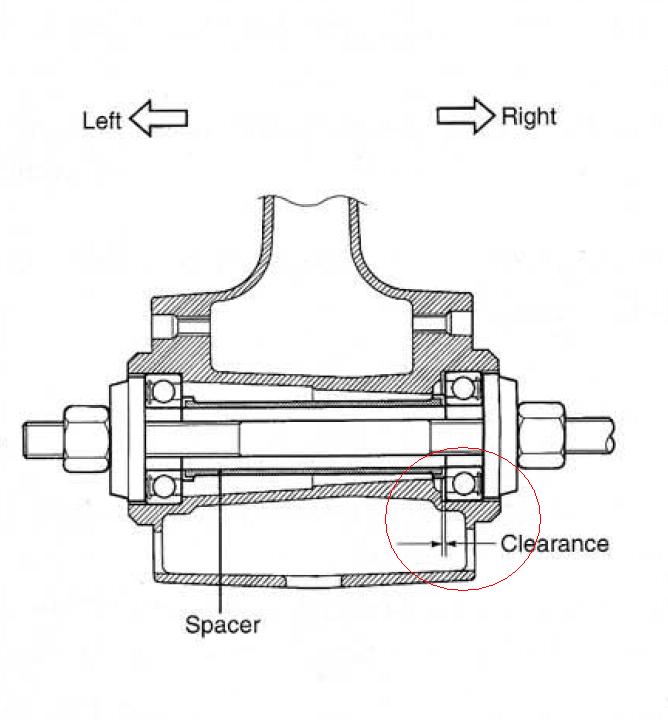

In that process the direction arrows have been ground off, making it harder to tell left and right.

It has also required replacing the wheel bearings in both sets.

I did not adhere to the instructions in the Suzuki manual (also the same in the Clymer manual) and I will explain why.

1. I feel that the design of the wheel is such that it would require both front wheel bearings (left and right) to finally come to rest with their outer races both flush (completely seated), and both inner races of each bearing pressing somewhat against the spacer.

If not then even if the axle was torqued to the proper specs, forces on the wheel would be able to cause the bearings to move about a little in a back and forth motion, within their recesses in the hub.

The inner races would be flush with the spacer, but if either one of the bearings was not seated flush, the whole affair could move sideways.

2. If the bearings are installed using the tool (which exerts force across the inner and outer race equally), then there is no chance of brinneling.

3. If however, the axle is used to move the right side bearing in the last bit until it is fully seated, then because the axle is only exerting force on the inner race, and the outer race is exerting resistance, then brinneling could occur.

4. I can’t see any difference between exerting the required torque on the axle to seat the right bearing, or using the tool to seat it to the same torque, except the tool puts the torque across the entire bearing face, minimizing the chance of brinneling.

So I installed the bearings, first one then the spacer, then the second and torqued them in with the tool, ( the same torque as the axle would require) making sure the spacer was exactly centered (or I would not get the axle in).

I have about 17,000 miles on a set done this way and no problems.

OH and BTW, the Haynes manual agrees with me and does not want a “clearance space” left on either bearing. (see below)

Glad your back Mr. Bogus, I value your thoughts on this.

).

).