You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

extension blocks :)

- Thread starter Busaboy1992

- Start date

More options

Meta tagsGixx1300R

Registered

I think I've seen/heard of just as many aftermarket swing-arm failures compared to extentsions. It almost always comes down to the material used and using a well-known product.

Also how it was designed

When you welded them in would under bracing be enough?

Gixx1300R

Registered

When you welded them in would under bracing be enough?

yes it would but I had extra tubing that I wanted to use

That's pretty cool. I have extensions on now and was thinking about welding them with under bracing and cutting off all that crap on the top for a better look.

Gixx1300R

Registered

Most bolt one swingarm extensions are made incorrectly. See pics

On my extensions there is a full 1 inch of billet material between the pocket (area that the axle is adjusted) and the tang (area that bolts into the stock swingarm. I have seen aftermarket extensions has only 1/4 inch material here. Also the axle ajuster bolt is drilled and tapped in this area so there may be as little as 1/4" x 2" material here in other extensions.

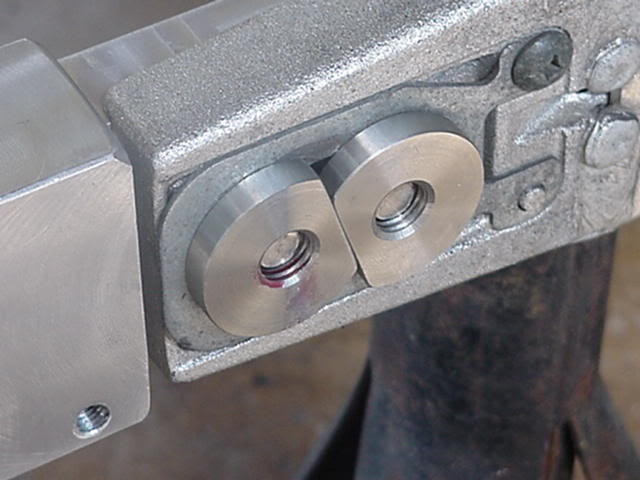

These are my stainless steel wellnuts. They spin and lock when torqued. Other extensions use a thin plate that is bolted to the threaded holes on the extension themselves. My wellnuts can be torqued to over 100lbs since the bolt and nuts are stainless.

On my extensions I radius this area. Other extensions do a 90 degree cut here. A radius will add strength and dampen vibrations. This area is prone to failure with a 90 degree machined cut.

On my extensions there is a full 1 inch of billet material between the pocket (area that the axle is adjusted) and the tang (area that bolts into the stock swingarm. I have seen aftermarket extensions has only 1/4 inch material here. Also the axle ajuster bolt is drilled and tapped in this area so there may be as little as 1/4" x 2" material here in other extensions.

These are my stainless steel wellnuts. They spin and lock when torqued. Other extensions use a thin plate that is bolted to the threaded holes on the extension themselves. My wellnuts can be torqued to over 100lbs since the bolt and nuts are stainless.

On my extensions I radius this area. Other extensions do a 90 degree cut here. A radius will add strength and dampen vibrations. This area is prone to failure with a 90 degree machined cut.

You do know who made that arm correct? It's not the arm, it's the lack of a rushed job by the customer and shop not doing as they normally do..

no gussets in a critical area..

Yes I know who built it. Why are you blaming the costomer? It's ultimately the builders responsibility to insure quality and safety of the product. Although it is very odd for that particular manufacture to have any defects.

Being down south, grudge racing is huge. Usually long bikes, big cc, high compression nitrous bikes grudge race here. 95% of them have evil, Adams, (and there's one other brand) arms on them. I'd say about every other month someone rips the dog bone pivot off the arm, or fold the arms like the one pictured. Yes those are the extreme cases, but continual use on an average street bike could end up with the same results over time. I won't risk that.

Thanks for all the info

I'm going to look at mine as soon as I get home to see how much meat mine have

Gixx1300R

Registered

I'm going to look at mine as soon as I get home to see how much meat mine have

let us know

I didn't say I blamed the customer, nor did I blame the shop that made the arm directly. I will spell it out for you. No customer should rush a shop to do anything cause rush jobs most time equates to incorrect jobs and the shop should never cut a corner to try and make a arm or any part for a customer fast without fufilling it's obligation to sell them a safe piece of equipment. Who would you blame if customer died? who would the family of the deceased blame? Blame, who would you blame if it was your own personal bike?

I come from the HOME of Grudge Racing, I have seen more fast stuff of all types of powersports growing up than most will see in this lifetime. Cutting corners cost you your name,products quality name and the most important loss could be life...I would never take money saved over the quality of a product and my customers won't either... We not ride or die bikers...We ride to keep from dying bikers. My customers lives are in my hands when I build them a bike, motor or supply them a part. We do it right or you can have someone else do it..Our lives depend on the sport we love and so do our families for us to get back home safe..

I come from the HOME of Grudge Racing, I have seen more fast stuff of all types of powersports growing up than most will see in this lifetime. Cutting corners cost you your name,products quality name and the most important loss could be life...I would never take money saved over the quality of a product and my customers won't either... We not ride or die bikers...We ride to keep from dying bikers. My customers lives are in my hands when I build them a bike, motor or supply them a part. We do it right or you can have someone else do it..Our lives depend on the sport we love and so do our families for us to get back home safe..

Yes I know who built it. Why are you blaming the costomer? It's ultimately the builders responsibility to insure quality and safety of the product. Although it is very odd for that particular manufacture to have any defects.

Being down south, grudge racing is huge. Usually long bikes, big cc, high compression nitrous bikes grudge race here. 95% of them have evil, Adams, (and there's one other brand) arms on them. I'd say about every other month someone rips the dog bone pivot off the arm, or fold the arms like the one pictured. Yes those are the extreme cases, but continual use on an average street bike could end up with the same results over time. I won't risk that.

Gixx1300R

Registered

I didn't say I blamed the customer, nor did I blame the shop that made the arm directly. I will spell it out for you. No customer should rush a shop to do anything cause rush jobs most time equates to incorrect jobs and the shop should never cut a corner to try and make a arm or any part for a customer fast without fufilling it's obligation to sell them a safe piece of equipment. Who would you blame if customer died? who would the family of the deceased blame? Blame, who would you blame if it was your own personal bike?

I come from the HOME of Grudge Racing, I have seen more fast stuff of all types of powersports growing up than most will see in this lifetime. Cutting corners cost you your name,products quality name and the most important loss could be life...I would never take money saved over the quality of a product and my customers won't either... We not ride or die bikers...We ride to keep from dying bikers. My customers lives are in my hands when I build them a bike, motor or supply them a part. We do it right or you can have someone else do it..Our lives depend on the sport we love and so do our families for us to get back home safe..

^^^^ This^^^^

Gixx1300r what do you think of this?

Gixx1300R

Registered

Gixx1300r what do you think of this?

I dont see a pic, can u repost it?

How about this time?

OK thanks buddy. This is the first set I have used and no one I know have them. I did use red loctite but was thinking of welding them but no idea if they are made out of good metal or cheap stuff.

Similar threads

- Replies

- 9

- Views

- 750

- Replies

- 16

- Views

- 7,689

- Replies

- 22

- Views

- 1,677