You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

German Tooltime

- Thread starter B-12

- Start date

More options

Meta tagsB-12

Registered

Thats gixxer's spray nozzle holder or a copy huh. Well a quick question I figure you may not have thought of----how do you know that most of that nos is not just going in one cylinder? That would not be a very good thing. That design just scares me looking at it. ??? You know any spray looks good when you hit it but what it does when you cant see inside that box at wide open throttle is something totally different even pointing it away you may still have it favoring a cylinder you do know what that means I hope? A favored cylinder will look like thisexcept it wont keep going

Thaught about this , but..........As a lot of dealers sell these holders there would be so much damaged engines we would hear about.

And..i think Gixxer and the others know what they are doing , going this way.

The plume will go in airbox thats right , but not dirctly to the stacks. The stuff then has to pass also the K&N and will be mixed well with the air.

Blowing in the rams is the same , but you have to fix the nozzles in the thin plastics.

Greater risk is to go with 4 lines into airbox. I saw at Hockenheim a nitrous guy (i know from Haya-board) with blown engine. One line got loose , and unfortunatly just sprayed in another intake.

So this one got dubble the stuff , went lean , and a melt piston.

Even if this was a wet system with fogger nozzles the result is the same.

Now he switched and has all lines outside.

Everybody with lines inside airbox......better check from time to time

lease:

lease:jeepinocala

Registered

Ok it makes more sense it is going befor the airfilter I did forget where the filter is on these bikes but here is another one -- Is it actually hitting the filter and freezing up against it? Good luck mine goes in both air intake tubes figuring that it would have a better chance of disbursing before the filter. Good luck please keep writing the final results after 20 shots or so.

Man, Bernie.. Can't wait to see the finished product.

Great job on the machine work also.. I'd be carefull w/ mounting that sucka as I know you will be. Something about nuts and bolts that could come loose inside the airbox scare me.. Now granted,.. they can't pass through the air filter to the cylinders, but I'm just saying...

P.S... You da man.. GoldenChild's got you HOOKED up!! Very nice.

Great job on the machine work also.. I'd be carefull w/ mounting that sucka as I know you will be. Something about nuts and bolts that could come loose inside the airbox scare me.. Now granted,.. they can't pass through the air filter to the cylinders, but I'm just saying...

P.S... You da man.. GoldenChild's got you HOOKED up!! Very nice.

I would epoxy it or use self tapping screws and silicone over them..

B-12

Registered

Man, Bernie.. Can't wait to see the finished product.

Great job on the machine work also.. I'd be carefull w/ mounting that sucka as I know you will be. Something about nuts and bolts that could come loose inside the airbox scare me.. Now granted,.. they can't pass through the air filter to the cylinders, but I'm just saying...

P.S... You da man.. GoldenChild's got you HOOKED up!! Very nice.

I saw that risc.

As my profession ist toolmaker , and i have some experience in mechanics , i thaugt about it and explain how il do it.

The nozzleholder has female treads , and the screwhead is in the airbox. So the screw will go trough the tread in the plate , and on outside i will mount selflocking nuts as addditional locknut.

With the o-ring i hope it will be leakproof.

Anyway i will check the mounting with dish soap or leaksearch spray.

Hope my terms are ok to explain. Il take some pics when done.

Thanks guys

Additional question

should i use velocity stacs with same lenght , or stay as it is ? (the two longs in the middle)

Think about equal distribution of the No2

Last edited:

B-12

Registered

Another small step further after holydays

It was so dammed cold that i had frozen fingers in the garage , and couldnt go on.

ImageShack Links Do Not Work

ImageShack Links Do Not Work

It was so dammed cold that i had frozen fingers in the garage , and couldnt go on.

ImageShack Links Do Not Work

Link no longer works ImageShack Links Do Not Work

Link no longer works B-12

Registered

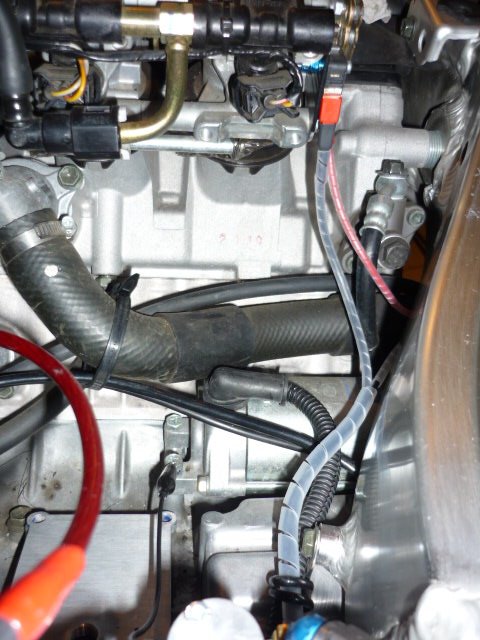

Final fit of solenoid.

Please comment , if you agree with it or if something must be changed. Its my first install.

Thanks to Daniel for support. and parts.

and parts.

Samco is just for protection of polyline. The line is finaly about 23 inch long. ok ??

With this lenght i have no bends. Could shorten it but then have to bend more.

Brass ellbow will be changed to Alu. The blue 4AN fitting is a filter with SS-filter-mesh inside.

Please comment , if you agree with it or if something must be changed. Its my first install.

Thanks to Daniel for support.

and parts.

and parts.Samco is just for protection of polyline. The line is finaly about 23 inch long. ok ??

With this lenght i have no bends. Could shorten it but then have to bend more.

Brass ellbow will be changed to Alu. The blue 4AN fitting is a filter with SS-filter-mesh inside.

Last edited:

B-12

Registered

Very clean install. Reroute your line from inbetween the throttle bodies. Run it on the side where the TPS is located. Also get a Nitrous filter and install it between the Bottle and the Solenoid. All Velocity stacks should be the same length.

Line now outside.

The blue fitting is wth SS-filter mesh inside.

Nozzle plate has tread for the screws , and the selflocking nuts are at the same time counternuts.

Fan nozzle blows towards stacks.

B-12

Registered

Today it made the first wooosh .

Good pressure , the poly hit me like a whip didnt expect this

didnt expect this

Toggled the horn button , looped +12 via WOT direct to solenoid. Switched ground from horn-button goes direct to solenoid.This way have +12 and ground switched separate and no risk of spraying on shortcut. Easy without relais.

I made a try with a 3A Fuse in the wire and only with my small tryout akku (1.2Amps) and it worked fine. Only a seconds or two but the 10A of the horn will need no relais.( Daniel)

Daniel)

I will only need one relais for the windowswitch which is to weak.

I´m happy

happy

(wires will be aranged propperly later)

My first install , and i will take any advice if you see something to do better.

Good pressure , the poly hit me like a whip

didnt expect this

didnt expect this

Toggled the horn button , looped +12 via WOT direct to solenoid. Switched ground from horn-button goes direct to solenoid.This way have +12 and ground switched separate and no risk of spraying on shortcut. Easy without relais.

I made a try with a 3A Fuse in the wire and only with my small tryout akku (1.2Amps) and it worked fine. Only a seconds or two but the 10A of the horn will need no relais.(

Daniel)

Daniel)I will only need one relais for the windowswitch which is to weak.

I´m

happy

happy

(wires will be aranged propperly later)

My first install , and i will take any advice if you see something to do better.

B-12

Registered

Found another used cheap solenoid on ebay , and use it as purge. Makes no sense  on my small shot.......???

on my small shot.......???

but a lot of fun.

Another weekend has passed with a bit of tooltime.

Hardware install is now nearly ready. Tested under pressure > no leaks

Last things are the brackets for the bottles ,and that will be a bit of work.

Will go with two 1lbs , with one on each side.

The relais is the only one i need and is for Gregs windowswitch.

The SS lines will later be wrapped. (no wires in range of them.the black is an additional ground for the tail)

Question: What makes a better efect on the purge outlet , a bigger or a small hole ?

on my small shot.......???

on my small shot.......???but a lot of fun.

Another weekend has passed with a bit of tooltime.

Hardware install is now nearly ready. Tested under pressure > no leaks

Last things are the brackets for the bottles ,and that will be a bit of work.

Will go with two 1lbs , with one on each side.

The relais is the only one i need and is for Gregs windowswitch.

The SS lines will later be wrapped. (no wires in range of them.the black is an additional ground for the tail)

Question: What makes a better efect on the purge outlet , a bigger or a small hole ?

Last edited:

I'm running straight poly line out the back, for my purge effect. I think the smaller the diameter the better effect; IMO. Gives it a louder higher pitch Psssssssssssssssssssssssssssst sound effect. Oh yeah.... don't forget the LED for lighting effect...lol. Chaaaching...Chaaaching...lmao

Looking good on your work.

Looking good on your work.

Last edited by a moderator: