mike1180

Banned

The challenge was to secure a busa with the minimum (or none) load on the suspension.

I have trailered bikes all my life and don’t believe in compressing the springs at all. I feel it takes some of the life out of the springs, and contributes to premature sag.

I have a trailer that I built 20 years ago with a 4000 pound axle with brakes and extremely strong, and I just can’t part with it.

I used this and had to get a ramp to fit it and be able to store in it when traveling.

The mounts consisted of:

- Baxley Sport Chock in the trailer position and with the safety lock on.

- hooks flush mounted in the trailer floor

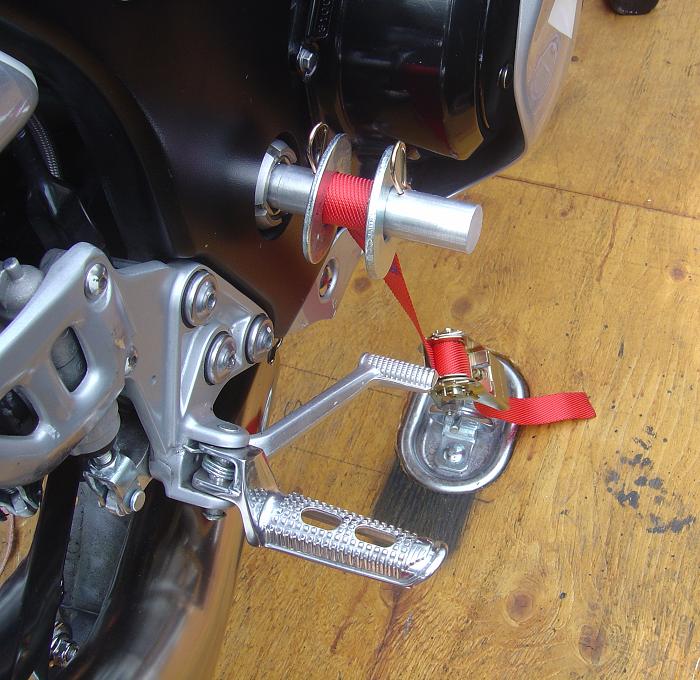

- 3 rods, each through the front axle, rear axle and swingarm (this one on the swingarm is just for safety, as when it is depressed it does compress the springs.) These rods can be 5/8 inch redirod, or as 2 of mine, aluminum stock cut down to fit.

With the 5/8 redirod on the front axle, the nut fits right into the axle on the one side.

I put the rear of the bike on a rear stand, and that gave it a lot more stability and took the load off the tire. I tied the rear stand down to the trailer, and then a loop for the tie down to fit in, and then another rope to tie the rear stand down further.

It all works good and I thought I would share as there may be some ideas someone could use.

I have trailered bikes all my life and don’t believe in compressing the springs at all. I feel it takes some of the life out of the springs, and contributes to premature sag.

I have a trailer that I built 20 years ago with a 4000 pound axle with brakes and extremely strong, and I just can’t part with it.

I used this and had to get a ramp to fit it and be able to store in it when traveling.

The mounts consisted of:

- Baxley Sport Chock in the trailer position and with the safety lock on.

- hooks flush mounted in the trailer floor

- 3 rods, each through the front axle, rear axle and swingarm (this one on the swingarm is just for safety, as when it is depressed it does compress the springs.) These rods can be 5/8 inch redirod, or as 2 of mine, aluminum stock cut down to fit.

With the 5/8 redirod on the front axle, the nut fits right into the axle on the one side.

I put the rear of the bike on a rear stand, and that gave it a lot more stability and took the load off the tire. I tied the rear stand down to the trailer, and then a loop for the tie down to fit in, and then another rope to tie the rear stand down further.

It all works good and I thought I would share as there may be some ideas someone could use.

i hope you were taking her some place to get dirty

i hope you were taking her some place to get dirty